Your lights just gone out, the fridge is warming, and you need power—fast. A portable generator rattles to life outside, and within minutes your home hums with electricity again. But have you ever wondered how does a portable electric generator work? What magic turns a few gallons of gasoline into life-saving 120 volts? The answer lies in a tightly choreographed dance between physics, engineering, and safety systems that most owners never see.

This guide strips away the mystery, walking you through the exact process your generator uses to convert fuel into usable power. You’ll learn what happens inside that metal box, why voltage stays steady even when your air conditioner kicks on, and the critical safety steps that keep both you and utility workers alive. By the end, you’ll understand exactly how does a portable electric generator work to keep your home running during emergencies.

Engine Combustion Spins the Crankshaft at 3,600 RPM

Your generator’s journey from fuel to electricity begins with a single-cylinder, four-stroke engine burning gasoline, propane, or diesel. Unlike your car engine that turns wheels, this powerplant has one mission: spin the crankshaft at precisely 3,600 revolutions per minute to produce 60 Hz alternating current required for North American appliances.

When you pull the starter cord or press the electric button, you initiate the combustion cycle that creates rotational energy:

- Intake stroke draws in the perfect fuel-air mixture through the carburetor

- Compression stroke squeezes this mixture to increase explosive force

- Power stroke ignites the mixture via spark plug, creating the explosion that drives the piston down

- Exhaust stroke pushes spent gases out through the muffler

Look for smooth acceleration to 3,600 RPM within 5 seconds—any sputtering indicates fuel mixture problems. Premium models with electronic fuel injection (EFI) start reliably even in freezing temperatures, while carbureted units may require choke adjustment below 40°F.

Alternator Magnets Generate Electricity Through Copper Coils

Mounted directly to the engine’s crankshaft, the alternator transforms mechanical rotation into electrical energy through electromagnetic induction. As the rotor—containing powerful magnets—spins at 3,600 RPM, its magnetic field cuts across stationary copper windings called the stator.

This interaction follows Faraday’s law: when a conductor moves through a magnetic field, it induces electrical current. The stator’s precisely arranged copper coils convert this movement into alternating current (AC) at exactly 60 Hz. Higher-end generators use brushless alternators with temperature-rated insulation (155°C class) that prevent melting under heavy loads while eliminating the need for maintenance-prone carbon brushes.

Pro tip: If your generator produces weak power even at full throttle, the rotor’s residual magnetism may have faded. Try “flashing the field” by briefly connecting a 12V battery to the exciter terminals—this restores the magnetic charge needed for proper voltage buildup.

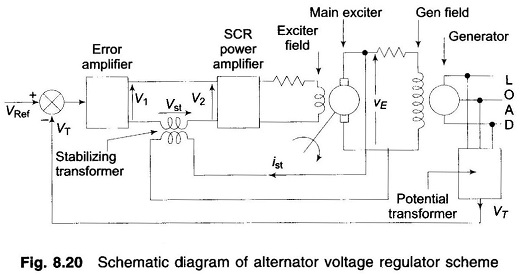

Voltage Regulator Stabilizes Power for Sensitive Electronics

Without regulation, your generator’s output would fluctuate wildly as appliances cycle on and off. The Automatic Voltage Regulator (AVR) constantly monitors output 60 times per second through a feedback winding, making micro-adjustments to maintain rock-steady 120V (or 240V split-phase).

Here’s the critical sequence when you plug in a high-draw appliance:

- Sensing: AVR detects voltage drop as load increases

- Comparing: Measures against ideal 120V target

- Adjusting: Increases DC current to rotor electromagnets

- Stabilizing: Restores voltage within 100 milliseconds

Conventional generators produce power with 15-20% total harmonic distortion (THD)—acceptable for lights and motors but potentially damaging to computers and medical equipment. Inverter generators add a crucial extra step, converting AC to DC and back to ultra-clean AC with less than 3% THD, making them safe for sensitive electronics.

Critical Safety Systems Prevent Electrocution and Fires

Before electricity reaches your outlets, multiple protection layers activate to prevent disasters. Thermal-magnetic circuit breakers trip at 120% of rated current to stop wire overheating, while Ground Fault Circuit Interrupters (GFCI) detect dangerous current leaks as small as 5 milliamps and shut down power in just 5 milliseconds—critical for outdoor or wet conditions.

Never skip this critical step: Always connect your generator frame to your home’s grounding electrode system using 6-gauge copper wire. This provides a safe path for fault current to reach earth, preventing electrocution if an internal short occurs. More importantly, never backfeed your home through a standard wall outlet without a transfer switch—this can send 7,000-10,000 volts onto utility lines, creating lethal hazards for lineworkers restoring power.

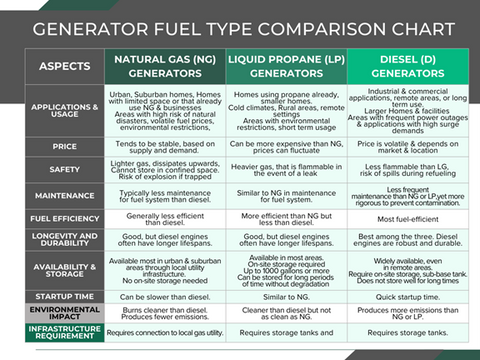

Gasoline vs. Propane vs. Diesel: Real-World Performance Differences

Your fuel choice dramatically impacts reliability, runtime, and cold-weather performance. Gasoline offers the best cold-start capability down to -20°C but degrades within three months without stabilizer. Expect 8-10 hours of runtime at 50% load from 4 liters in a typical 2kW unit.

Propane stores indefinitely in sealed cylinders and produces cleaner emissions, though vaporizers may ice up below -10°C. A standard 20-pound tank provides 10-11 hours at 50% load. Diesel delivers the highest energy density with 12-14 hours runtime from 4 liters at 50% load, but requires glow plugs for cold starts below freezing.

Expert note: Dual-fuel models let you switch between gasoline and propane without engine modification—ideal for extended outages when one fuel becomes scarce. Propane’s cleaner burn also reduces carbon buildup during long storage periods.

Why Your Microwave Can Run But Your AC Struggles to Start

Understanding starting watts versus running watts explains why some appliances work while others stall your generator. Motors draw 3-7 times their running current during startup—a 1,800-watt air conditioner might need 5,400 watts for just 3 seconds to overcome inertia.

Here’s what happens when you plug in multiple appliances:

- Simultaneous startup: Connecting high-draw devices at once often trips breakers

- Sequential starting: Turn on high-wattage appliances one at a time with 30-second intervals

- Eco-throttle benefit: Inverter models reduce engine speed under light loads, saving 40% fuel

- Parallel capability: Two compatible inverter generators can combine outputs to handle larger starting surges

For homes needing backup power, a 5-8kW generator typically handles refrigerator (600W), furnace fan (800W), sump pump (1,200W), and essential electronics for 8-10 hours overnight.

8-Step Pre-Start Safety Checklist Every Owner Must Complete

Before pulling that starter cord, complete this critical safety verification:

- Inspect fuel lines for cracks or leaks—replace if hardened or brittle

- Check oil level via dipstick—fill to upper mark with SAE 10W-30

- Verify grounding—confirm 6-gauge copper wire connects to grounding rod

- Confirm transfer switch position—must isolate utility power completely

- Position outdoors ≥20 feet from windows/doors, downwind of living areas

- Use proper extension cords—only 3-prong, outdoor-rated cables sized for load

- Never refuel hot engines—wait 15 minutes minimum after shutdown

- Install CO alarms—battery-operated units in all sleeping areas

Skipping any step risks carbon monoxide poisoning, electrical fire, or electrocution. Generators kill more people annually from CO poisoning than electrical faults—always operate outdoors with proper ventilation.

Essential Maintenance Tasks That Prevent Generator Failure

A neglected generator becomes useless when you need it most. Follow these intervals religiously:

- Every 25 hours: Clean air filter in dusty conditions—tap gently to remove debris

- Every 50 hours: Change oil (100 hours with synthetic)—drain while warm for complete removal

- Every 100 hours: Replace spark plug—check gap at 0.7-0.8 mm before installation

- Annually: Replace air filter regardless of usage hours—stale fuel degrades seals

For storage, either drain all fuel or add stabilizer at 1 ounce per 2.5 gallons, then run until carburetor is dry. Exercise your generator for 10 minutes monthly with a 50% load to keep seals lubricated and prevent fuel system clogs. This simple routine ensures your generator will start reliably when the next outage hits.

Understanding how does a portable electric generator work transforms you from a passive user to an informed operator who can maximize performance, ensure safety, and extend equipment life. When the lights go out next time, you’ll have more than noise and exhaust—you’ll have reliable, well-understood backup power exactly when you need it most.