Your phone charger buzzes, your laptop flickers, and that camping trip generator sounds like a jackhammer. Inverter generators solve these problems through a clever three-stage process that delivers clean, quiet power. Unlike traditional generators that run full-throttle regardless of demand, these modern units adjust their engine speed automatically, using 20-40% less fuel while protecting your sensitive electronics.

This guide breaks down exactly how inverter generators transform raw mechanical energy into the pure sine wave power that keeps your devices safe and your neighbors happy. You’ll discover why professionals and outdoor enthusiasts increasingly choose this technology for reliable, electronics-friendly power anywhere.

Three-Stage Power Conversion Process

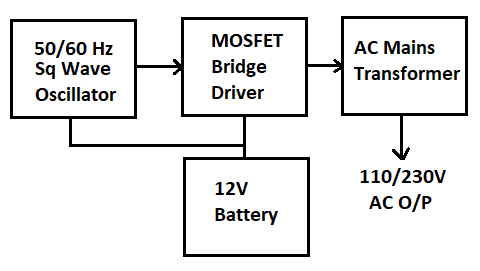

Inverter generators revolutionize electricity generation through AC-DC-AC conversion. This process transforms unstable raw power into computer-grade electricity through three distinct phases working in perfect harmony, creating power quality superior to your home electrical grid.

Stage 1: Variable-Speed AC Generation

The journey begins with a compact alternator spinning 2,500-5,000 RPM—dramatically different from conventional generators locked at 3,600 RPM. This variable speed system responds instantly to your power needs, generating high-frequency AC between 1,000-20,000 Hz.

Key advantages of variable speed operation:

– Engine slows during light loads (phone charging)

– Speeds up for heavy demands (air conditioner startup)

– Reduces noise by 50% compared to fixed-speed units

– Extends engine life through reduced wear

Unlike traditional generators that maintain constant speed regardless of demand, the inverter generator’s engine only works as hard as necessary. This raw power contains voltage spikes and harmonic distortion that would damage sensitive electronics—making the next stages critical for creating safe, stable electricity.

Stage 2: Precision DC Conversion

High-frequency AC enters a full-wave bridge rectifier where high-speed diodes convert it to DC power. This stage operates at 95%+ efficiency while handling 1,000-7,000 watts depending on generator size.

What happens during rectification:

– AC sine waves become DC voltage

– Active power factor correction maximizes usable output

– DC bus voltage stabilizes between 150-400V

– Ripple voltage filtered for smooth current flow

The DC stage acts as an electrical buffer, isolating your devices from engine speed fluctuations and fuel quality variations. This conversion is crucial because DC power can be precisely controlled before being transformed back to AC in the final stage.

Stage 3: Digital AC Reconstruction

A microprocessor-controlled inverter module reconstructs perfect AC power using high-frequency switching at 10-50 kHz. This digital signal processor continuously monitors and adjusts:

- Voltage precision: Maintains 120V within 1%

- Frequency stability: Locks at 60 Hz within 0.1 Hz

- Harmonic purity: Keeps distortion under 3%

- Load response: Adjusts within 100-200 milliseconds

The result? Power quality superior to your home electrical grid, safe for computers, medical equipment, and anything with a microprocessor. Unlike conventional generators that produce “modified sine wave” power full of electrical noise, inverter generators deliver pure sine wave output that sensitive electronics require.

Smart Engine Management System

Your inverter generator’s brain continuously balances power demand against fuel efficiency. Electronic throttle control responds to electrical load measured through current transformers, calculating optimal RPM every millisecond.

Real-time adjustments include:

– Idle-down during phone charging (2,500 RPM)

– Power boost for refrigerator startup (4,500 RPM)

– Eco-mode optimization for steady loads

– Quiet operation at 52-60 dB (conversation level)

This intelligence is why inverter generators use 20-40% less fuel than conventional models. When you’re only charging your phone, the engine doesn’t need to run at full capacity—it automatically adjusts to the minimal speed required, saving fuel and reducing wear.

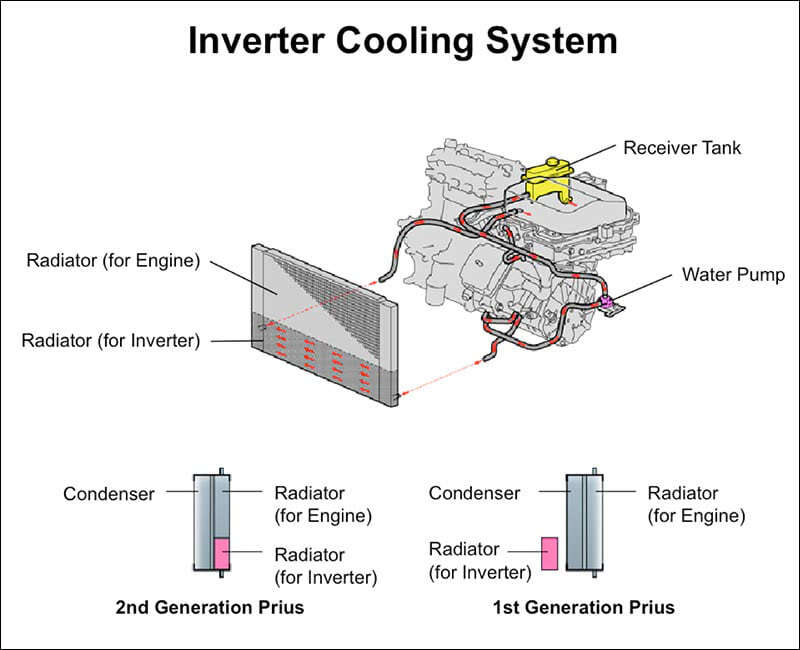

Advanced Cooling Architecture

Variable-speed cooling prevents overheating while maintaining compact size. Temperature sensors on inverter heat sinks trigger automatic fan speed adjustments, while rubber mounts isolate vibration for neighbor-friendly operation.

Cooling system features:

– Forced-air circulation with smart fan control

– Automatic thermal derating prevents damage

– Optimized airflow for variable-speed engines

– Heat sink monitoring every 10 seconds

This sophisticated thermal management allows inverter generators to maintain high performance even during extended use, unlike conventional units that often overheat when pushed to capacity.

Performance Metrics That Matter

Power Quality Specifications

- Voltage regulation: ±1% from no-load to full-load

- Frequency stability: ±0.1 Hz under all conditions

- Total harmonic distortion: <3% (pure sine wave)

- Crest factor: 1.41 (ideal for electronics)

These specifications explain why your laptop doesn’t flicker and your phone charger doesn’t buzz when connected to an inverter generator. The electricity produced is cleaner than what comes from many standard wall outlets.

Efficiency Advantages Over Conventional Generators

- Fuel savings: 20-40% reduction across all loads

- Extended run time: 8-12 hours on 1-1.5 gallons

- Part-load efficiency: High efficiency down to 25% load

- Standby consumption: <1 watt in eco-mode

This efficiency means you’ll spend less time refueling and more time enjoying your power. For a weekend camping trip, an inverter generator might need just one tank of gas versus multiple fill-ups with a conventional unit.

Digital Features and Smart Technology

Eco-Throttle System Operation

The eco-throttle responds to load changes within 100-200 milliseconds, adjusting engine speed between 2,500-5,000 RPM. This predictive system anticipates power demands, preventing voltage dips during motor startup. When your RV air conditioner kicks on, the generator instantly boosts power without causing lights to dim.

Intelligent Display Systems

Modern units feature LCD displays showing real-time data:

– Wattage output with load percentage

– Voltage and frequency monitoring

– Fuel level with remaining run time

– Maintenance countdown timers

– Error code diagnostics

These displays transform your generator from a simple power source into an intelligent energy management system you can monitor and control with precision.

Safety Systems and Protections

Electronic Safety Features

- Low-oil shutdown: Stops engine at 0.2L remaining

- Overload protection: 110% capacity automatic shutdown

- Over-temperature: Activates at 105°C inverter temp

- Short-circuit: Instantaneous electronic disconnection

- CO-Minder: Carbon monoxide auto-shutdown

These safety systems work automatically to protect both your equipment and yourself. Unlike conventional generators that might keep running until catastrophic failure, inverter generators shut down safely before damage occurs.

Real-World Applications

Electronics Safe Operation

Perfect for sensitive devices:

– Laptop computers and servers

– Medical equipment (CPAP, oxygen concentrators)

– Audio/video production gear

– LED lighting systems

– Variable frequency drives

This is why photographers, medical professionals, and IT technicians increasingly rely on inverter generators—they deliver power clean enough for the most sensitive equipment.

RV and Camping Power

Ideal for recreational use:

– Air conditioner startup capability

– Microwave and entertainment systems

– Battery charging systems

– Climate control operation

– Quiet 52-60 dB operation

The quiet operation means you can run your generator overnight in campgrounds without disturbing fellow campers—a major advantage over noisy conventional models.

Limitations to Consider

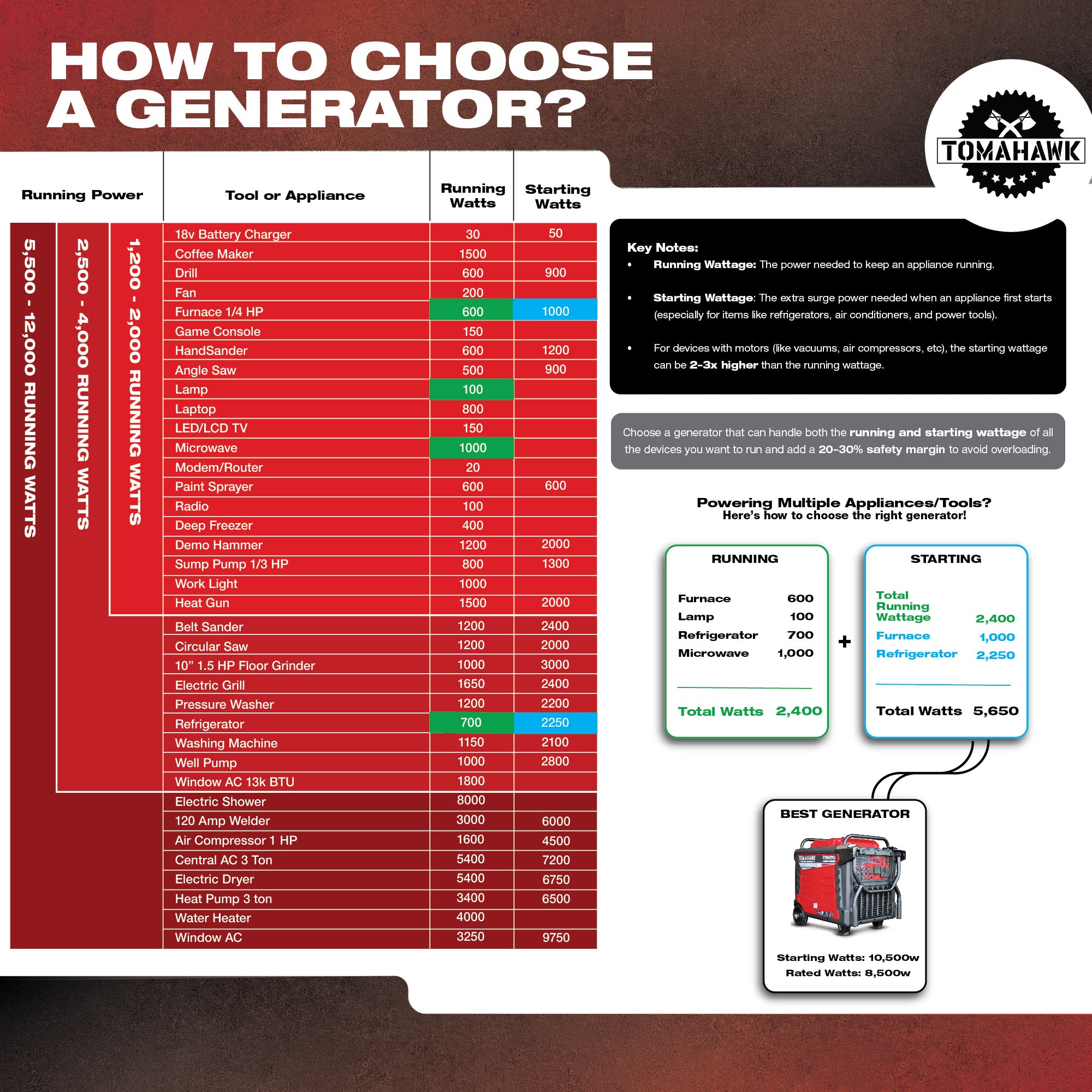

Power Output Constraints

- Maximum continuous: 1,000-7,000 watts (consumer models)

- Surge capacity: 110-120% for 10-30 seconds only

- Not suitable: Whole-house backup applications

- Parallel limit: Two-unit maximum connection

While inverter generators excel at powering sensitive electronics and moderate loads, they’re not designed for whole-house backup during extended power outages. For most recreational and professional applications, however, their output capabilities are more than sufficient.

Cost and Complexity Factors

- Initial price: 2-4x higher than conventional generators

- Repair complexity: Specialized electronics require expert service

- Parts availability: Limited compared to traditional units

- Theft risk: Higher value requires security measures

The higher upfront cost pays dividends in fuel savings, reduced maintenance, and protection for your valuable electronics. Over the generator’s lifetime, the total cost of ownership often becomes competitive with conventional models.

Key Takeaway: Inverter generators transform unstable raw power into clean, computer-grade electricity through sophisticated AC-DC-AC conversion. This three-stage process delivers fuel savings, noise reduction, and electronics protection that conventional generators simply cannot match. Choose based on your power needs, but expect 2-4x higher initial investment for technology that pays dividends in fuel savings and equipment protection. For anyone who relies on sensitive electronics away from grid power, understanding how an inverter generator works reveals why it’s become the smart choice for clean, reliable portable power.