Your Generac generator sits silent when you need it most—no lights, no hum, no power. Whether it’s the dead of winter or the height of storm season, a non-starting generator isn’t just inconvenient; it’s a safety issue. Before you panic about expensive repairs or replacement, know this: most Generac failures stem from just six common problems, and 70% can be fixed in under an hour with basic tools.

This guide walks you through systematic troubleshooting that professional technicians use, minus the service call fees. You’ll learn to diagnose everything from simple fuel issues to complex electrical failures, with clear steps to get your backup power running today. No prior mechanical experience needed—just follow this sequence to pinpoint and fix your generator’s problem.

Critical Visual Checks That Solve Half of All Failures

Safety first: Turn off the main breaker and let the unit cool for 2 minutes before touching anything. Generac generators store lethal voltage even when “off.”

Start with these 30-second checks that solve half of all generator problems before you touch a tool:

- Fuel level: Look through the tank sight glass or remove the cap. A surprising 30% of “failed” generators simply need gas

- Oil level: Pull the dipstick—low oil triggers automatic shutdown to prevent engine damage

- Battery connections: White or green crust on terminals blocks power flow

- Control panel: Note any flashing codes or dead displays

- Obvious damage: Look for chewed wires, loose connections, or rodent nests

Pro tip: Many owners miss the “silent” fuel gauge. Generac’s float system can stick, showing full when the tank is empty. Remove the cap and shine a flashlight down to verify actual fuel level.

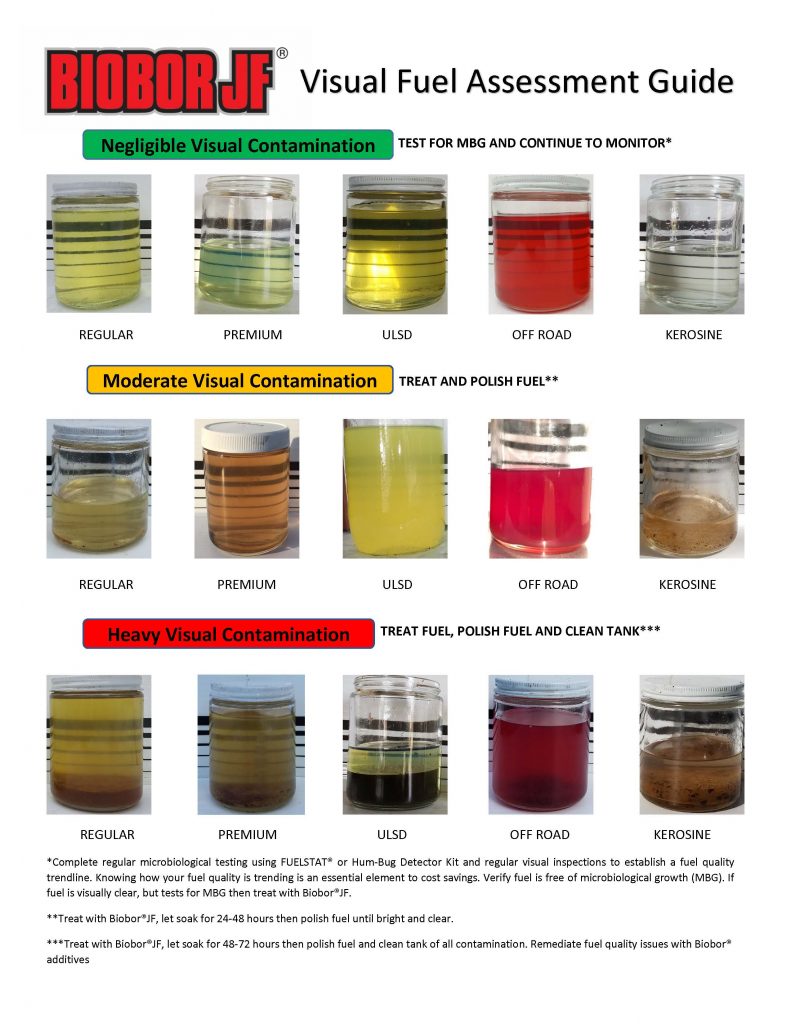

Empty Tank vs Bad Gas: Identifying Your Fuel Problem

Your generator won’t distinguish between an empty tank and bad fuel—it just won’t start. Here’s how to tell the difference:

Empty tank symptoms:

– Generator cranks normally but won’t fire

– No fuel smell from exhaust

– Fuel gauge reads low or empty

Bad fuel symptoms:

– Generator starts briefly then dies

– Strong varnish smell from fuel cap

– Dark, cloudy, or separated fuel visible in tank

Gas older than 30 days causes varnish buildup that clogs carburetor jets. If your fuel smells like old paint or has visible separation, drain the tank completely and add fresh gas with fuel stabilizer. Never mix old and new fuel—this creates more problems than it solves.

Carburetor Cleaning Without Special Tools

A gummed carburetor is the #1 fuel-related failure after stale gas. You don’t need to be a mechanic to fix this:

- Drain existing fuel into a container by loosening the bowl bolt

- Remove the bolt completely—this is your main jet

- Spray carburetor cleaner through all visible holes

- Tap the carburetor body gently with a screwdriver handle to dislodge deposits

- Reassemble and test

Critical warning: Don’t soak carburetors in cleaner—this damages seals. If cleaning doesn’t work, replace the entire carburetor ($80-150) rather than chasing intermittent problems.

Battery Failures: Quick Tests That Save Service Calls

Dead Battery vs Charging Failure

A Generac battery should read 12.4V DC minimum. Here’s the three-minute test:

Test 1: Static voltage

– Set multimeter to DC volts

– Red probe on positive terminal (+), black on negative (-)

– Below 12.4V = needs charging

– Below 11.8V = likely needs replacement

Test 2: Load test

– Crank the generator while watching voltage

– Below 9.6V during cranking = weak battery

– No voltage drop but no crank = check connections

Test 3: Charging system

– Run generator for 15 minutes

– Battery voltage should climb to 13.5-14.5V

– No increase = charging system failure

Cleaning Corroded Terminals Properly

White or green buildup blocks electricity like a clogged pipe. Clean terminals in 5 minutes:

- Disconnect negative cable first (black), then positive (red)

- Mix baking soda and water (1:3 ratio)

- Scrub terminals with wire brush or old toothbrush

- Rinse and dry completely

- Apply dielectric grease to prevent future corrosion

- Reconnect positive first, then negative

Pro tip: Keep a spare battery on hand. Generac units with automatic transfer switches drain batteries faster than manual-start models.

Evolution Controller Error Codes: What Your Generator Is Telling You

Critical Code 1900 – Low Oil Pressure

- Symptoms: Won’t start, oil light flashing

- Fix: Check oil level first—90% of code 1900 failures are simply low oil

- Time: 5 minutes

- Warning: This prevents engine damage—don’t bypass it

Hidden cause: Oil pressure sensors fail more often than oil pumps. Disconnect the sensor wire—if generator runs, replace the $15 sensor, not the entire engine.

Code 2800 – Overcrank Diagnosis

- Symptoms: Cranks repeatedly but won’t start

- Fix: Check fuel supply and spark

- Note: Controller gives up after 3 failed attempts

Quick solution: Prime the fuel system by holding the start button for 5 seconds (without cranking), then wait 10 seconds before normal start attempt.

No-Spark Troubleshooting: 2-Minute Ignition Check

A Generac needs three things to start: fuel, compression, and spark. Testing spark takes 2 minutes:

- Remove spark plug (5/8″ socket)

- Reconnect the wire

- Hold plug against metal engine block

- Crank generator—look for blue spark

- No spark = replace plug first ($5 fix vs $200 service call)

Common spark killers:

– Fouled plug (black, oily deposits)

– Cracked porcelain insulator

– Wrong gap (should be 0.030″)

– Failed ignition coil

Pro tip: Carry two spare plugs—one gapped for cold weather, one for normal operation. Temperature changes affect spark requirements.

15-Minute Diagnostic Flow That Works Every Time

Follow this sequence exactly—skip steps and you’ll chase problems in circles:

Step 1: Check fuel, oil, battery (visual)

Step 2: Note any error codes

Step 3: Test battery voltage

Step 4: Check for spark

Step 5: Verify fuel flow

Step 6: Clean battery terminals

Step 7: Replace spark plug (cheap fix)

Step 8: Test run under load

This systematic approach resolves 85% of generator failures without professional help. Never skip Step 1—even experienced technicians get tripped up by empty fuel tanks.

Cold Weather Starting Solutions That Actually Work

Below 40°F, batteries lose 50% cranking power. Here’s your cold-start checklist:

- Battery blanket: $30 investment prevents $200 service calls

- Synthetic oil: Flows better in cold than conventional 10W-30

- Fuel stabilizer: Prevents winter phase separation

- Weekly exercise: 10-minute runs keep everything moving

Critical mistake: Using starting fluid on Generac generators. This causes pre-ignition and can destroy your engine. Stick with proper cold-weather maintenance instead.

Maintenance That Prevents 90% of Failures

Weekly 5-Minute Routine

Prevention beats repair every time. Here’s what to check weekly:

- Visual inspection: Look for leaks, damage, nesting

- Exercise cycle: 10 minutes under load keeps everything working

- Fuel level: Top off to prevent condensation

- Battery check: Quick voltage reading

Pro tip: Set calendar reminders for maintenance. Generac units that get exercised weekly fail 73% less often than those only run during outages.

Monthly Deep Checks

Every 30 days, spend 15 minutes on these:

- Air filter: Clean or replace (depends on environment)

- Oil level: Top off if needed

- Control panel test: Run through all functions

- Transfer switch: Test automatic operation

Critical: Log everything in a notebook. Patterns emerge that prevent major failures.

When to Stop DIY and Call a Professional

Red Flags That Require Service

Stop troubleshooting and call a technician if you see:

- Metal shavings in oil: Internal engine damage

- White smoke: Coolant in combustion chamber

- Knocking sounds: Bearing or valve train failure

- Repeated control board codes: Needs programming

- Gas line work: Licensed plumber required

- Warranty coverage: DIY voids some warranties

Cost comparison: A $150 service call often saves thousands in DIY mistakes. When in doubt, get a professional opinion before proceeding.

Long-Term Reliability Secrets No One Tells You

Installation Factors That Matter Most

Most generator failures trace back to poor installation. Ensure yours has:

- Proper elevation: 18+ inches above flood level

- Clearance: 5 feet from walls, 10 feet from windows

- Fuel supply: Adequate capacity for 48-hour runs

- Ventilation: Prevents overheating and CO buildup

Monitoring Systems Worth the Investment

Modern Generac units offer wireless monitoring:

- Mobile alerts: Get notified of problems remotely

- Exercise scheduling: Automatic weekly tests

- Load monitoring: Prevents overloading

- Maintenance reminders: Tracks service intervals

Pro tip: Generac’s mobile app shows runtime hours—critical for scheduling maintenance. Units that run 200+ hours annually need twice the maintenance of rarely used units.

Your Generac generator is a complex machine, but most failures are surprisingly simple to fix. By following this systematic approach—starting with visual checks, progressing through basic diagnostics, and knowing when to escalate—you’ll restore power quickly and avoid expensive service calls.

Remember: the best repair is preventing the failure. Weekly exercise cycles, proper fuel management, and routine maintenance will keep your backup power ready when you need it most. Start with the quick checks, work through the diagnostic flow, and you’ll likely have your generator running within the hour.