Your Generac generator sits ready to power your home during outages, but the startup process can feel intimidating—especially under stress. Whether facing an approaching storm or testing your weekly exercise routine, knowing exactly how to activate your backup power source is essential for every homeowner. When utility power fails, seconds count, and hesitation could mean hours without electricity for critical systems.

This guide walks you through the complete startup sequence, from pre-operation safety checks to troubleshooting common startup failures. By the end, you’ll confidently start your Generac generator in under two minutes, regardless of your model type. Proper startup technique prevents damage to your valuable backup power system while ensuring reliable performance when you need it most.

Pre-Startup Safety Checklist

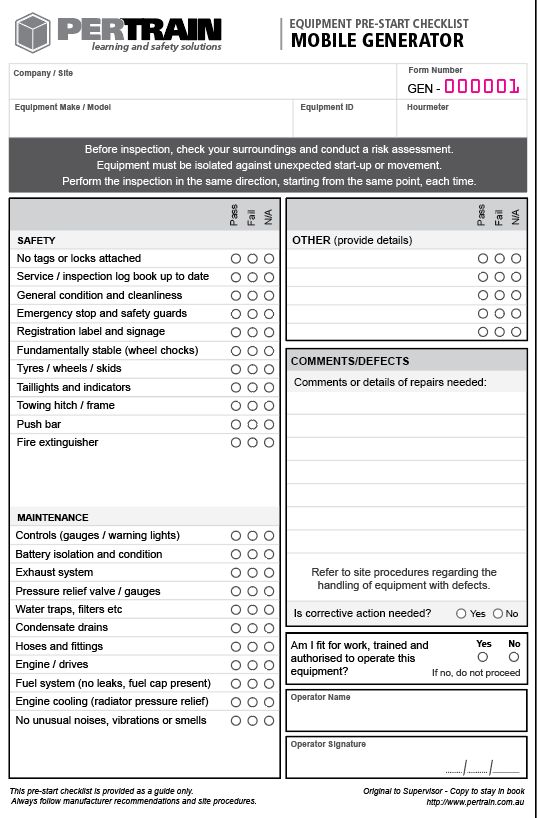

Before touching any controls, verify these critical safety elements to prevent damage or injury. Generac generators require specific safety protocols that differ from portable units, making these checks non-negotiable for proper operation.

Fuel Level Verification

Check your fuel gauge or tank level—never attempt startup below 25% capacity. For propane models, ensure tank valves are fully open and pressure readings show green. Natural gas units require confirmation of steady supply pressure at the main shutoff valve. Low fuel levels can cause air locks in the system, preventing proper startup and potentially damaging the fuel pump.

Clearance and Ventilation

Remove any debris within 5 feet of the generator enclosure. Verify exhaust vents face away from windows, doors, and air intakes. Check for ice buildup, leaves, or nesting materials that could restrict airflow. Generac units require unobstructed airflow for proper cooling—blocked vents trigger automatic shutdowns that prevent startup completion. During winter months, pay special attention to snow accumulation around the unit.

Electrical Disconnections

Turn OFF the main circuit breaker in your home’s electrical panel. This prevents dangerous backfeed when the generator starts. For manual transfer switch setups, switch to “OFF” position before proceeding. Failure to disconnect properly can send power back into utility lines, creating lethal conditions for line workers and potentially destroying your generator’s electrical components.

Locating Your Control Panel

Generac generators feature intuitive control panels, but location varies significantly by model series. Identifying your specific control interface is the first step to successful startup.

Standby Generator Panels (9-20kW)

Open the front access door to reveal the control interface. You’ll find a digital display, AUTO/OFF/MANUAL switch, and LED indicator lights. The main breaker sits directly below or beside the control module. Most newer models feature backlit displays that activate when you approach the unit, making nighttime operation safer and more intuitive during actual power outages.

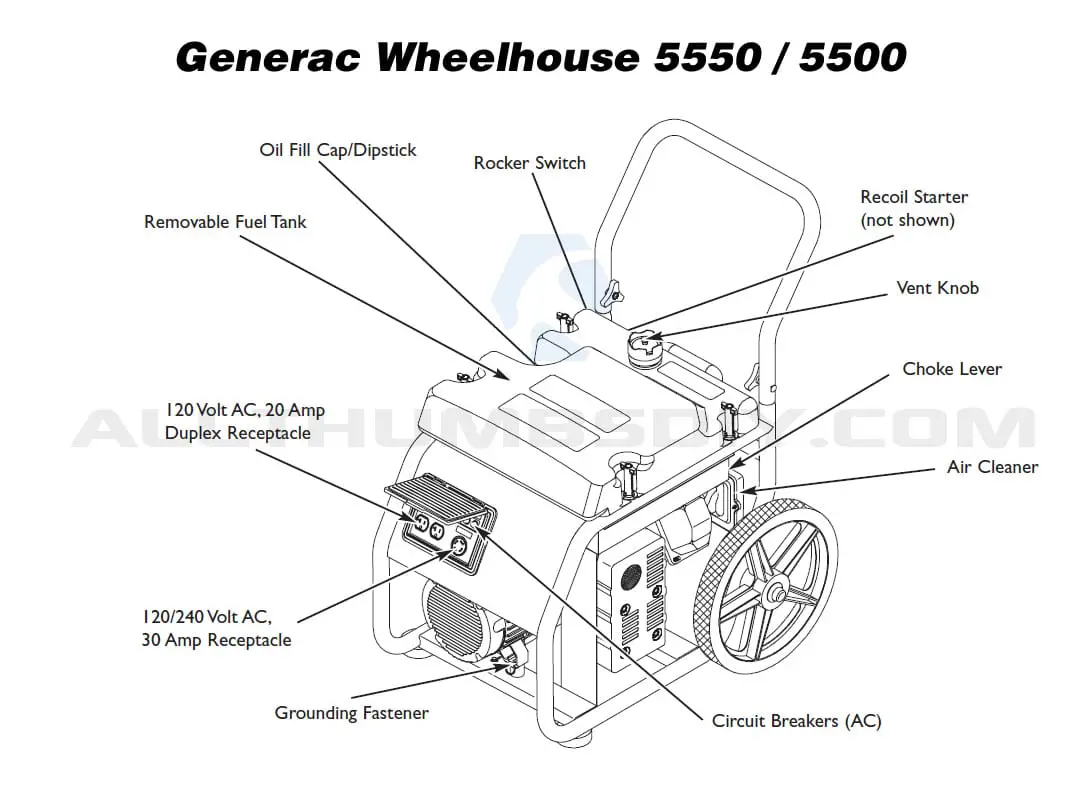

Portable Generator Panels

Look for the control panel on the side opposite the pull-cord. Key components include the fuel valve, choke lever, engine switch, and power outlets. Some models integrate these into a single control bank. Portable units require more manual intervention during startup compared to standby models, making familiarity with each control critical for successful operation.

Manual Startup Sequence

Follow these precise steps in order—deviating from the sequence risks flooding the engine or electrical damage. Generac specifically designed their startup procedure to protect sensitive components while ensuring reliable ignition.

Step 1: Fuel System Activation

Turn the fuel valve to “ON” position. For propane models, this means opening the service valve fully clockwise. You’ll hear a brief hiss as pressure equalizes—this is normal and indicates proper fuel system engagement. Skipping this step is the most common reason for failed startups among first-time users.

Step 2: Control Switch Sequence

Move the generator switch to “MANUAL” (standby models) or “ON” (portables). The digital display should illuminate immediately, showing system status. Wait 3-5 seconds for system initialization—this allows the control board to perform self-diagnostics before attempting startup. Rushing this step causes unnecessary strain on electrical components.

Step 3: Engine Start Methods

Electric Start: Press and hold the start button until the engine catches (usually 3-5 seconds). Release immediately when running—extended cranking damages the starter. If the engine doesn’t catch after 5 seconds, wait 10 seconds before trying again to prevent starter motor overheating.

Recoil Start: Pull the cord firmly until you feel resistance, then give a smooth, full pull. Avoid yanking or partial pulls that can flood the carburetor. Proper technique requires using your full arm strength with a steady motion, not quick jerks that damage the recoil mechanism.

Automatic Startup Settings

Configure your generator for hands-free operation during actual outages after verifying manual startup works correctly.

AUTO Mode Configuration

Flip the control switch to “AUTO” after successful manual testing. The generator now monitors utility power and starts automatically within 10 seconds of outage detection. LED indicators show “READY” status when properly configured—typically a solid green light with no error codes displayed. Test this feature monthly during your exercise routine to ensure reliability.

Exercise Timer Programming

Access the control menu to set weekly exercise cycles. Most Generac models default to 12 minutes every Tuesday at 2:00 PM. Adjust timing to minimize noise disruption—early morning or mid-afternoon work best for most neighborhoods. These automatic tests keep engine components lubricated and identify potential issues before actual emergencies.

Common Startup Failures

When your generator won’t start, systematic diagnosis saves hours of frustration and ensures power restoration when you need it most.

No Response When Switched On

Check battery voltage—standby units need 12.4V minimum. Clean corroded terminals with baking soda solution and wire brush. Replace batteries older than 3 years regardless of charge status. The control panel should illuminate when you approach the unit; if not, the problem is almost certainly battery-related.

Cranks But Won’t Start

Verify fuel supply and prime the system. For gasoline models, pump the primer bulb 5-7 times until firm. Propane units may need 2-3 minutes for pressure stabilization before retrying. This symptom often indicates fuel starvation rather than an engine problem—addressing the fuel system first resolves most cases.

Model-Specific Variations

Different Generac series require slight modifications to standard procedures. Understanding your specific model prevents unnecessary troubleshooting.

Guardian Series (9-22kW)

These air-cooled models feature a single control switch without manual choke. The system auto-chokes based on temperature sensors. Startup involves simply switching to “MANUAL” and waiting for the 5-second pre-start sequence. These units require less user intervention but need regular air filter maintenance to prevent overheating.

Portable GP Series

These compact units include a fuel shutoff valve separate from the engine switch. Always open the fuel valve before attempting startup, then close it after shutdown to prevent carburetor fouling. Portable models require more frequent oil checks and manual choke adjustment based on ambient temperature.

Post-Startup Verification

Confirm proper operation before relying on your generator during emergencies. Many homeowners make the critical mistake of assuming “running equals working.”

Load Transfer Testing

With the generator running, switch your transfer switch to “GENERATOR” position. Listen for smooth engagement—grinding or clicking indicates contactor issues. Verify power at selected circuits using a simple lamp or outlet tester. Never assume power is flowing correctly without physical verification.

Performance Monitoring

Watch the control display for the first 5 minutes. Normal readings include voltage at 240V ±5% and frequency at 60Hz ±1%. Significant deviations indicate potential problems that require professional service before relying on the unit during an extended outage.

Maintenance for Reliable Starts

Prevent startup failures with these monthly and seasonal tasks that take less than 15 minutes but ensure years of reliable service.

Battery Care Essentials

Test battery voltage monthly using a multimeter. Clean terminals quarterly with a wire brush and apply dielectric grease. Replace batteries showing less than 12.4V after charging or older than 36 months. The battery is the most common failure point in standby generators—proactive replacement prevents 90% of “no-start” emergencies.

Fuel System Maintenance

Run the generator under load for 30 minutes monthly to prevent fuel stabilization. Add fuel stabilizer to portable generators if unused for 60+ days. Drain and replace gasoline older than 90 days—ethanol blends degrade quickly and cause carburetor clogs that prevent startup.

Key Takeaway: Mastering your Generac startup routine requires practicing the manual sequence monthly and maintaining critical components proactively. Schedule these 15-minute sessions during calm weather—your future self will thank you when storms knock out utility power at 2 AM.

Remember: A properly maintained Generac generator starts reliably for 20+ years. The few minutes you invest today in learning and practicing these procedures ensure your family’s comfort and safety during any power emergency. When seconds count during a blackout, your familiarity with these steps means the difference between immediate power restoration and hours in the dark.