When the lights flicker and go out during a severe storm, a diesel generator springs to life within seconds, restoring power to hospitals, data centers, and homes. This seamless transformation—from diesel fuel in a tank to reliable electricity at your outlets—happens through a precisely engineered sequence of mechanical and electromagnetic processes. Understanding how does a diesel generator work reveals the sophisticated engineering behind these critical power sources that keep essential services running when the grid fails.

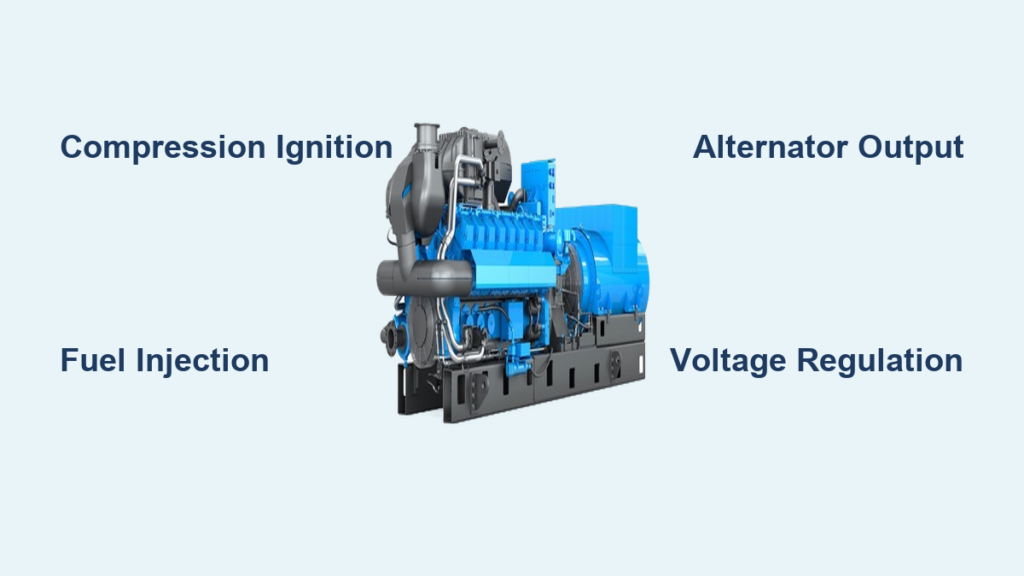

Diesel generators serve as the backbone of emergency power systems worldwide, converting chemical energy stored in diesel fuel into electrical energy through a sophisticated integration of engine mechanics and electromagnetic principles. The process involves multiple subsystems working in perfect synchronization, from fuel injection to voltage regulation, ensuring consistent power output regardless of load demands. Whether you’re selecting a backup power system for your business or troubleshooting an existing unit, knowing the inner workings helps optimize performance and reliability.

Diesel Engine Combustion Process Step-by-Step

Air Compression Creates Spontaneous Ignition Conditions

The magic begins with the diesel engine’s compression-ignition technology, which eliminates the need for spark plugs. As the piston moves upward in the cylinder, it compresses incoming air to extreme pressures between 14-23 bar, heating it to 700-900°C—hot enough to instantly ignite diesel fuel. This extreme compression is what makes diesel engines more efficient than gasoline counterparts, as they can achieve higher compression ratios without pre-ignition problems.

Precise Fuel Injection Triggers Power Stroke

At the exact moment of peak compression, high-pressure common-rail injectors deliver atomized diesel fuel (operating at 1,500-2,500 bar pressure) directly into the combustion chamber. The fuel immediately vaporizes and ignites from contact with the superheated air, creating a rapid pressure expansion that drives the piston downward with tremendous force. This controlled explosion releases the chemical energy stored in diesel, converting it into mechanical energy that rotates the crankshaft.

Why Diesel Doesn’t Need Spark Plugs

Unlike gasoline engines, diesel relies solely on compression heat for ignition—a fundamental difference that makes diesel generators more reliable for emergency power. The absence of spark plugs eliminates a critical failure point, allowing diesel generators to start consistently even after months of standby. This compression-ignition principle also contributes to diesel’s superior fuel efficiency, typically delivering 3 kWh of electricity per liter of fuel consumed at optimal loading.

Alternator Electricity Generation Mechanism

Crankshaft Rotation Powers Electromagnetic Conversion

The engine’s crankshaft transfers mechanical energy directly to the alternator through a robust coupling or flywheel system. At precisely 1,500 RPM for 50 Hz systems or 1,800 RPM for 60 Hz systems, this rotational energy spins the alternator’s rotor within the stator assembly. This direct mechanical connection ensures immediate power production without energy conversion losses found in other generator types.

Electromagnetic Induction Creates Three-Phase AC Power

Inside the alternator, the spinning rotor—containing electromagnetic field coils—creates a rotating magnetic field that sweeps past stationary copper windings in the stator. This relative motion between magnetic fields and conductors induces electrical current through electromagnetic induction, generating three-phase alternating current ready for immediate use. The output voltage typically ranges from 120/208V to 13,800V depending on the generator’s size and application.

How Voltage Regulation Maintains Stable Output

The automatic voltage regulator (AVR) constantly monitors output voltage and adjusts the strength of the alternator’s magnetic field by controlling excitation current to the rotor windings. When electrical loads fluctuate—like when large motors start—the AVR instantly compensates to keep voltage within ±1-2% of nominal values. This prevents damaging voltage spikes that could destroy sensitive equipment during sudden load changes.

Critical Systems for Reliable Generator Operation

Governor Control Prevents Frequency Instability

Electronic governors continuously monitor engine speed and adjust fuel delivery to maintain precise rotational speed regardless of electrical demand. When you connect additional equipment, the governor increases fuel injection to counteract the load increase, preventing frequency drift that could damage connected devices. Modern systems achieve remarkable stability with frequency variations of less than 0.5% during normal operation.

Why Proper Loading Maximizes Efficiency and Lifespan

Diesel generators operate most efficiently at 65-80% of their rated capacity, delivering optimal fuel economy while minimizing maintenance issues. Running significantly below capacity causes incomplete combustion and “wet stacking,” where unburned fuel accumulates in the exhaust system. Conversely, sustained overloading increases wear dramatically and reduces operational lifespan. For emergency applications, engineers typically size systems to operate at 75% load during outages for best performance.

Automatic Transfer Switch Activation Sequence

When utility power fails, the automatic transfer switch (ATS) detects the outage within milliseconds and sends a start command to the generator controller. The battery-powered starter motor engages the engine’s flywheel, spinning the crankshaft until cylinder temperatures reach self-sustaining combustion levels—typically within 10-15 seconds. Once the generator reaches proper voltage and frequency, the ATS transfers the load from utility to generator power, often with less than a 10-second interruption.

Performance Factors Affecting Generator Efficiency

How Altitude and Temperature Impact Output

Generator efficiency decreases with altitude due to reduced air density, requiring derating of 3-4% per 1,000 feet above sea level. High ambient temperatures also reduce power output as cooling systems struggle to maintain optimal operating temperatures. Modern installations compensate with oversized radiators and jacket-water heaters that maintain engine temperature between 32-49°C for instant start capability, even in freezing conditions.

Fuel Consumption Patterns During Operation

Fuel consumption scales linearly with electrical load, making accurate sizing crucial for efficiency. A 100 kW generator consumes approximately 25 liters per hour at full load but only 8-10 liters per hour at 25% load. For critical applications, engineers typically size fuel tanks for minimum 8-hour runtime at 75% load to ensure adequate backup duration while avoiding the problems associated with extended low-load operation.

Essential Maintenance for Long Generator Life

Critical Preventive Maintenance Tasks

Regular maintenance intervals typically occur every 250 operating hours or 6 months, whichever comes first. Essential tasks include oil and filter changes, fuel filter replacement, coolant level checks, and battery terminal cleaning. Load bank testing every 3-6 months ensures generators can handle rated capacity while burning off accumulated carbon deposits that cause wet stacking during extended standby.

Troubleshooting Common Generator Problems

Unusual exhaust smoke provides immediate diagnostic clues: black smoke suggests over-fueling or air restriction, blue indicates oil burning from worn piston rings, and white points to coolant entering combustion chambers. Gradually increasing fuel consumption often indicates injector wear or air filter restriction, while difficulty starting frequently points to weak batteries or fuel system contamination.

Environmental Compliance and Noise Control

Modern Emissions Control Technologies

Today’s diesel generators incorporate advanced emissions control meeting EPA Tier 4 Final and EU Stage V standards. Diesel oxidation catalysts convert carbon monoxide and hydrocarbons to carbon dioxide and water, while selective catalytic reduction systems inject urea solution to reduce nitrogen oxide emissions by up to 90%. These technologies have dramatically reduced the environmental impact of diesel generators while maintaining their reliability advantages.

Effective Noise Reduction Methods

Sound-attenuated enclosures reduce noise levels to below 65 dB(A) at 7 meters—comparable to normal conversation—through multi-layer acoustic panels that combine sound-absorbing materials with resonant chambers. Critical installations near residential areas may require additional sound barriers or remote radiator placement to meet strict noise ordinances while maintaining operational efficiency.

Final Note: Diesel generators transform chemical energy in fuel into reliable electricity through precise coordination of compression-ignition engines and electromagnetic alternators. This proven technology provides immediate backup power for critical applications, with modern systems achieving 30-35% efficiency while meeting strict environmental standards. Understanding how does a diesel generator work helps ensure proper selection, operation, and maintenance of your backup power system, keeping lights on when you need them most. Regular load testing and adherence to maintenance schedules will maximize reliability and extend your generator’s operational life well beyond 20 years for standby applications.