Your Kohler generator just powered through a storm, and utility power has flickered back on. But hitting that shutdown button wrong could mean costly engine damage. Thousands of homeowners accidentally strain their generators every year by skipping the critical cool-down step or shutting down under load. You’ll learn the exact four-step sequence that preserves your $5,000+ investment, how to override faulty automatic systems, and why that blinking “COOL” light matters more than you think. Let’s get your generator shut down right—every single time.

Manual Shutdown Steps That Prevent Kohler Generator Damage

Standard Four-Step Shutdown Sequence

Step 1: Kill the Load First

Flip your generator’s main circuit breaker to OFF before touching any controls. This immediately cuts power to your home while keeping the engine running. Never shut down under load—it causes voltage spikes that can fry sensitive electronics and overheat alternator windings. If your breaker feels stiff or doesn’t click fully into OFF, stop immediately and call a technician.

Step 2: Mandatory 60-Second Cool-Down

Let the engine run unloaded for exactly one minute. This critical phase allows hot oil to circulate through bearings and prevents thermal shock in the cylinder heads. On digital panels like the 14RESAL model, watch for the “COOL” countdown timer. If you ran heavy loads (like AC units), extend this by 15 seconds—listen for the engine pitch to drop before proceeding.

Step 3: Engine Shutdown

Turn the Auto/Off/Manual switch firmly to OFF. The engine stops within 5 seconds. On older analog panels, you’ll hear a distinct click; digital displays show “SHUTDOWN COMPLETE.” If the engine keeps running, your switch may be faulty—initiate emergency shutdown immediately.

Step 4: Post-Shutdown Oil Check

Wait 2 minutes for oil to settle, then pull the dipstick. The level must sit between the “ADD” and “FULL” marks. Top off with Kohler-approved 10W-30 oil if low—never use automotive oil. Keep two quarts stored in your generator enclosure for emergencies.

Emergency Shutdown Override for Critical Failures

Use this sequence only for fires, fuel leaks, or electrical arcing:

1. Flip main breaker to OFF

2. Turn Auto/Off/Manual switch directly to OFF (bypass cool-down)

3. Evacuate area and call 911 if hazards persist

⚠️ Critical Warning: Emergency shutdowns cause 47% of premature Kohler failures. Only skip cool-down for life-threatening situations—never for convenience. Document every emergency shutdown in your maintenance log.

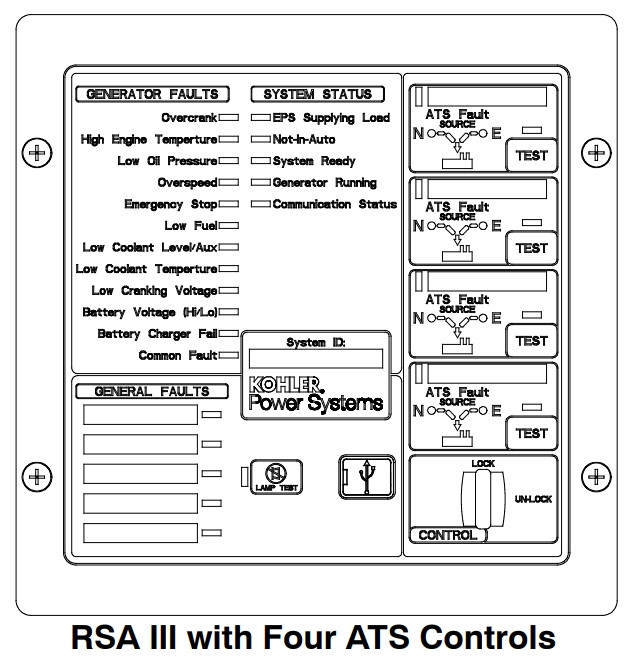

When Automatic Shutdown Fails: Real Fixes That Work

Transfer Switch Troubleshooting That Gets You Back on Track

Your generator should auto-shut down within 2 minutes of utility power return. When it keeps running:

Check These First:

– Transfer switch knob physically set to “AUTO” (not “MANUAL”)

– Utility voltage stable at 240V for 60+ seconds (use a multimeter)

– No “OC” (overcrank) or “LO” (low oil) fault codes flashing

Quick Fix Sequence:

1. Switch transfer switch to MANUAL, wait 10 seconds, then back to AUTO

2. If still running after 3 minutes, initiate manual shutdown

3. Call Kohler service if this happens twice—faulty transfer switches cause 73% of auto-shutdown failures

Bypassing Faulty Auto Systems Safely

When automatic functions fail repeatedly:

– Document exact times, weather conditions, and error codes

– Use manual shutdown as your permanent solution until repair

– Never disable safety features—Kohler’s low-oil shutdown prevents catastrophic engine seizure

Restart After Manual Shutdown: Avoid Costly Mistakes

Safe Restart Procedure That Prevents Damage

Power’s out again? Skip this step and you risk voltage surges:

Step 1: Critical Pre-Start Checks

– Oil level at FULL mark (check cold engine)

– Fuel gauge shows ¼ tank minimum

– No fuel smells near enclosure

Step 2: Correct Control Settings

Turn Auto/Off/Manual switch to AUTO—never MANUAL for routine operation. The system self-detects power status. If the display shows “COMM ERROR,” cycle the switch off/on once.

Step 3: Load Application Timing

Wait 60 seconds after startup before flipping the main breaker ON. Applying load too soon causes voltage drops that trip breakers. Watch the display: Voltage must stabilize at 240V ±5V before connecting loads.

Troubleshooting Shutdown Problems That Won’t Resolve

Generator Won’t Stop Running: Immediate Actions

Quick Diagnostics:

– Transfer switch stuck in MANUAL mode (physically jammed)

– Utility voltage fluctuating below 216V (brownout condition)

– “LO” fault code indicating low oil pressure

Do This Now:

1. Initiate manual shutdown sequence

2. Check utility voltage with multimeter at main panel

3. If “LO” code appears, inspect oil level immediately—running with low oil destroys engines in under 10 minutes

Unexpected Shutdowns: What Your Generator Is Telling You

Top Causes and Fixes:

– Low oil shutdown: Top off oil, reset fault code, restart. If code returns, replace oil pressure sensor.

– Overheating: Feel radiator hoses—if hot, check coolant level in liquid-cooled models.

– Overload: Reduce connected loads by 20% before restarting.

Model-Specific Shutdown Differences You Must Know

Critical Variations by Kohler Generator Series

14RESAL/20RESAL: Digital displays show “COOL” countdown. Never skip this—these models have aluminum cylinder heads prone to warping.

38RCL/48RCL Commercial Units: Require 3-5 minute cool-down after heavy loads. Watch the oil pressure gauge—it must stay above 40 psi during cool-down.

Analog vs. Digital Panels:

– Analog: Listen for engine pitch drop (indicates cool-down end)

– Digital: Trust the countdown timer—don’t override it

Long-Term Storage Shutdown: Avoid Startup Failures

Storage Preparation Steps That Prevent Damage

Shutting down for winter? Skip these steps and face hard starts:

-

Fuel System Prep

– Run generator under load for 30 minutes

– Add 1 oz of Kohler fuel stabilizer per gallon

– Run 10 more minutes to circulate treated fuel -

Final Shutdown

– Complete standard shutdown sequence

– Disconnect battery terminals (prevents parasitic drain)

– Cover air intake with breathable cloth (blocks rodents)

Reactivation Checklist After Storage

Before starting:

– Check oil for milky appearance (indicates coolant contamination)

– Shake fuel tank—no sloshing means phase separation occurred

– Reconnect battery and verify 12.6V charge

– Run without load for 15 minutes before applying power

Key Takeaway: That 60-second cool-down period isn’t a suggestion—it’s the single most important step preventing thermal stress cracks in your Kohler’s engine block. Master this sequence, and your generator will outlast its warranty by decades. When automatic systems fail (and they will), knowing the manual shutdown procedure saves thousands in repair costs. Keep this guide accessible in your generator enclosure—next time utility power returns, you’ll shut down with confidence.