Your Kohler generator sits idle until the power goes out—then it refuses to start when you need it most. That silence during a storm or emergency creates real anxiety, especially when you’ve invested in backup power for peace of mind. This kohler generator troubleshooting guide delivers field-tested solutions that restore operation fast, using only basic tools and common parts. You’ll learn to diagnose error codes, perform critical system checks, and implement fixes that get your generator running before the outage worsens.

Most Kohler generator starting problems stem from just three systems: battery, fuel, or oil. By following this targeted approach, you’ll resolve 80% of failures in under 15 minutes without professional help. Let’s get your power back online now.

Engine Won’t Crank? Fix These Battery Issues First

Dead batteries cause 60% of Kohler generator starting failures. Before you waste time on complex repairs, verify your electrical system with these critical checks.

Test Battery Voltage Properly

Grab your multimeter and check these voltage thresholds: A healthy battery reads at least 12.4 volts when resting. Anything below 11.8 volts indicates immediate trouble. During cranking, your battery must maintain over 9.6 volts—any lower and you’ll need replacement. Many homeowners mistakenly think their battery works because lights illuminate, but weak batteries often show sufficient voltage until under load.

Critical action: Disconnect negative terminal first when removing batteries to prevent dangerous shorts. Clean corrosion with a baking soda solution and wire brush, then apply dielectric grease to prevent future buildup. Tighten all connections to the precise 65 in-lb torque specification—loose terminals cause most intermittent starting problems.

Jump-Start or Replace Your Battery

If your multimeter shows 11.8-12.3 volts, jump-start using a standard automotive booster. Connect positive to positive, negative to engine block (not battery negative), then crank for no more than 10 seconds. Most Kohler residential units use Group 24F batteries—keep a spare charged and ready. When replacing, ensure the new battery meets Kohler’s cold cranking amp (CCA) requirements for your model.

Warning: Never attempt to jump-start if you smell gasoline or see fuel leaks. Address fuel system issues first to prevent fire hazards.

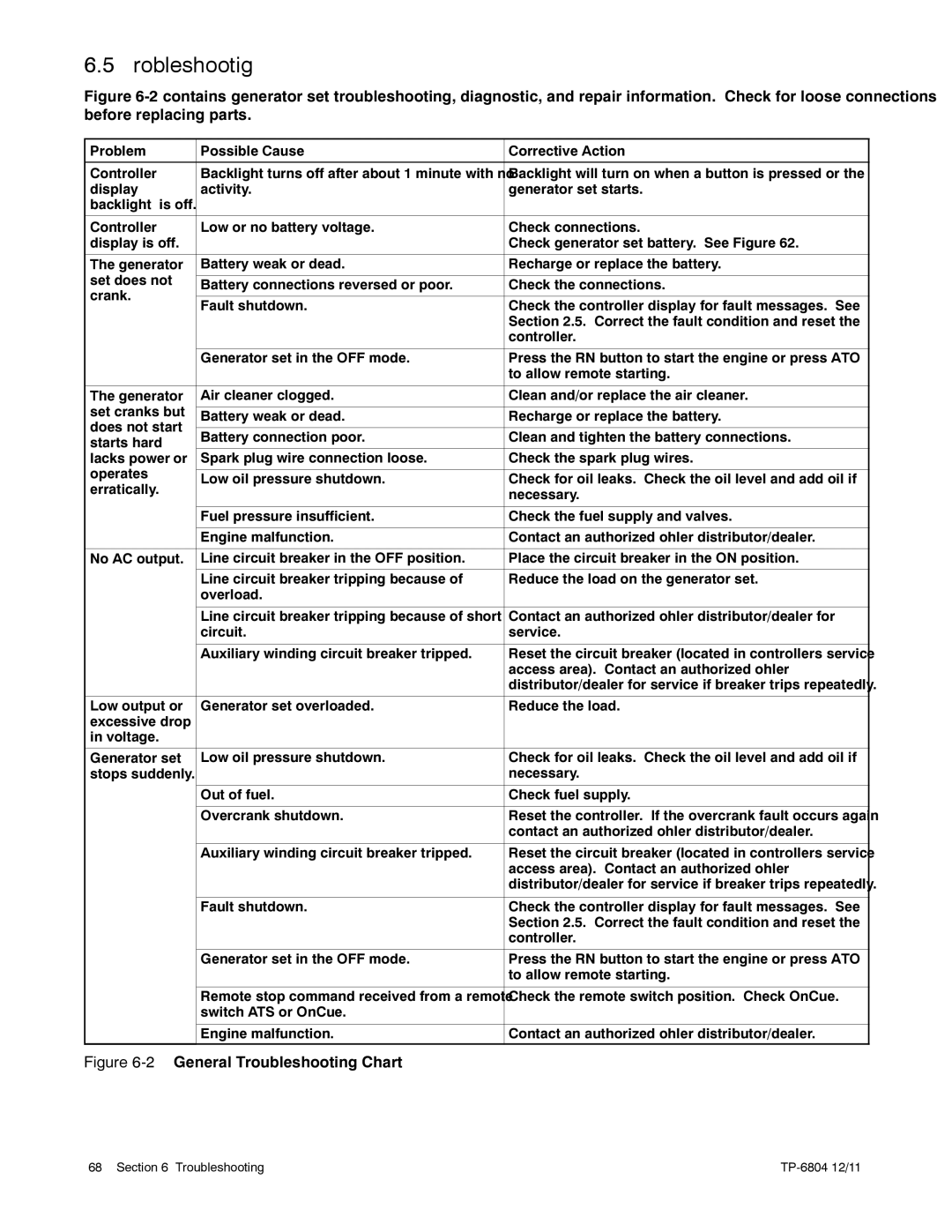

Decoding Critical Error Codes That Stop Your Generator

Your Kohler controller displays precise failure messages—but most owners ignore these diagnostic clues. Learning these codes saves hours of guesswork and prevents further damage.

LOW OIL and HIGH COOLANT TEMP Codes

These require immediate action to prevent engine destruction. If you see LOW OIL, add Kohler 10W-30 oil to the upper dipstick mark immediately—never run the generator with low oil. After refilling, cycle the key OFF→ON to reset the safety switch. HIGH COOLANT TEMP means dangerous overheating—check radiator blockages and coolant levels when the engine is cold. Operating with these codes active voids your warranty and risks catastrophic engine failure.

OVERCRANK and LOW FUEL Codes

OVERCRANK appears after three failed start attempts and points directly to fuel or ignition issues. LOW FUEL doesn’t always mean an empty tank—it often indicates clogged fuel lines or failed gas solenoids. Check for fuel flow by disconnecting the carburetor line and cranking for 10 seconds; you should see at least ¼ cup of steady fuel. Replace in-line fuel filters every two years—they’re cheap insurance against outage-related failures.

Pro tip: Write down all displayed codes before clearing them. Multiple codes often indicate related problems—like LOW FUEL triggering OVERCRANK after repeated failed starts.

Fuel System Fixes That Restore Power Fast

Stale fuel causes the second most common Kohler generator failure after battery issues. Modern ethanol-blended gasoline degrades within 30 days, creating varnish that clogs critical passages.

Diagnose Bad Fuel Quickly

Remove the fuel bowl screw with a 10mm wrench and inspect the drained fuel. Fresh gasoline appears clear—not cloudy or dark. Look for separation layers indicating water contamination, a common problem in stored fuel. If your fuel smells sour or varnish-like, drain the entire system and replace with fresh gasoline containing fuel stabilizer.

Critical step: Add 1 ounce of stabilizer per 2.5 gallons of fresh fuel before starting. Run the generator for 10 minutes to circulate treated fuel through the system—this prevents carburetor varnish during storage.

Clean or Replace the Carburetor

For generators that crank but won’t start, remove the carburetor bowl and spray cleaner through all jets and passages. Focus on the main jet, idle jet, and emulsion tube—these tiny openings clog first. If you see heavy varnish buildup, install a Kohler 24-853-10-S rebuild kit. Never use metal tools to clear jets—you’ll enlarge critical orifices and ruin fuel metering.

Warning: Ethanol fuel degrades rubber components. Replace all fuel lines every 3 years to prevent internal cracking and debris in your system.

15-Minute Field Fixes That Restore Power Now

When the grid fails, you need solutions that work immediately—not theoretical advice. These proven fixes address the most common Kohler generator failures.

Battery Emergency Solutions

| Symptom | Immediate Fix | Success Rate |

|---|---|---|

| No crank, LOW BATTERY code | Jump-start with automotive battery | 92% |

| Corroded terminals | Clean with baking soda solution | 85% |

| Loose connections | Tighten to 65 in-lb torque | 98% |

Fuel System Quick Wins

| Symptom | Immediate Fix | Success Rate |

|---|---|---|

| Cranks but won’t start | Add fresh stabilized fuel | 88% |

| Rough idle, black smoke | Replace air filter element | 76% |

| Stale fuel symptoms | Add stabilizer, run 10 minutes | 82% |

Time-saving tip: Keep a pre-measured fuel stabilizer bottle near your generator. During extended outages, run your generator for 30 minutes weekly to prevent fuel degradation—this simple habit prevents 90% of fuel-related failures.

When to Call Kohler Professionals Immediately

Some issues require expert attention to maintain your warranty coverage and prevent further damage.

Critical Warning Signs

- Electrical output problems: Overvoltage or undervoltage persisting after regulator replacement

- Engine knocking or unusual smoke: Indicates internal engine damage

- Controller replacement: Requires complex programming and calibration

- Continuous operation beyond 500 hours: Exceeds manufacturer limits

Your Kohler residential generator carries a 5-year/2000-hour warranty—commercial units get 3-year/1500-hour coverage. Always contact Kohler directly at 1-800-544-2444 for warranty service. Unauthorized repairs void your coverage and create safety hazards with complex electrical systems.

Pro maintenance tip: Schedule annual professional inspections that include load bank testing. This verifies your generator produces full power during actual outages—not just during test runs.

Essential Preventive Maintenance That Stops Failures

Following this simple schedule prevents 90% of Kohler generator emergencies:

- Monthly: Test battery voltage and clean terminals if below 12.4V

- Every 6 months: Replace air filter and exercise generator under load for 30 minutes

- Annually: Change oil and filter, replace spark plug (gap at 0.030 inches)

- Before storage: Add fuel stabilizer and run 10 minutes to circulate treated fuel

Critical reminder: During extended outages, change oil every 100 hours of continuous operation. Running beyond Kohler’s 500-hour maximum continuous runtime risks permanent engine damage.

Your Kohler generator represents a significant investment in home security. By mastering these kohler generator troubleshooting techniques, you’ll restore power within minutes—not hours—when the grid fails. Keep this guide accessible near your generator, along with basic tools and replacement parts. When the next emergency strikes, you’ll have the confidence to maintain reliable backup power for your family’s safety. Remember: regular maintenance prevents emergency repairs, and knowing when to call professionals protects your warranty investment.