Your generator’s engine oil type isn’t just a maintenance detail—it’s the lifeblood determining whether your power source delivers when disaster strikes or fails catastrophically during a critical outage. Choosing the wrong oil can trigger expensive repairs or complete generator failure, leaving you powerless when you need it most. Whether you’re running a portable unit at a construction site or relying on a standby system for home backup, understanding the precise generator engine oil type for your specific model and conditions means the difference between reliable power and costly downtime.

Most generator failures during emergencies trace back to improper lubrication. The right oil maintains viscosity across temperature extremes, prevents harmful deposits, and reduces wear that accumulates even during short operation cycles. This guide cuts through the confusion to deliver exactly what you need to know about selecting, maintaining, and maximizing your generator’s performance through proper oil selection—no technical jargon, just actionable information that protects your investment.

Gasoline Generator Oil Requirements

Gasoline-powered portable and inverter generators demand specific oil formulations that handle their unique operating characteristics. These units experience rapid temperature changes, variable loads, and often sit unused for extended periods—conditions that challenge conventional motor oils.

Why Standard Car Oil Fails in Generators

Car engine oils lack the specialized additives needed for small generator engines that operate at higher RPMs and experience different combustion byproducts. Using standard automotive oil leads to increased carbon deposits and faster viscosity breakdown. Valvoline Premium Blue One Solution Gen 2 stands out as the optimal generator engine oil type for gasoline units, specifically engineered for the thermal stresses and combustion characteristics of generator engines.

Climate-Driven Viscosity Selection

Your local weather dictates the ideal viscosity grade:

– Freezing conditions (below 32°F): 5W-30 or 0W-20 synthetic oil flows properly for instant cold starts

– Temperate zones: 5W-30 conventional or synthetic provides balanced performance

– Extreme heat (above 90°F): 10W-30 or 10W-40 maintains protective film during sustained operation

Diesel Generator Oil Specifications

Diesel generators face unique lubrication challenges due to higher compression ratios, increased soot production, and extended operation cycles. Standard oils can’t handle the thermal stress and contaminant load these engines produce.

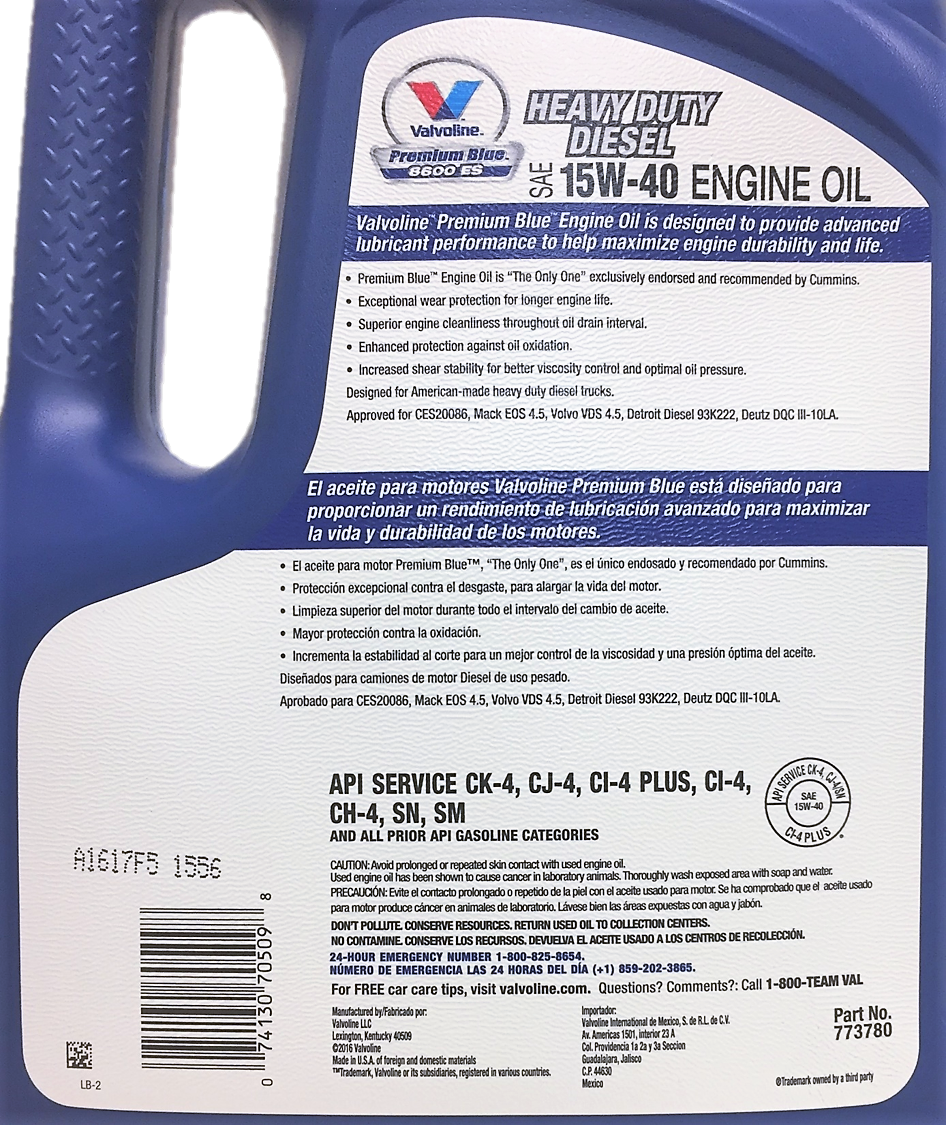

Heavy-Duty Oil Formulations for Diesel Units

Valvoline Premium Blue (Diesel Specific) delivers the robust protection diesel generators require, with additives that neutralize acidic byproducts and suspend soot particles. For RV diesel generators, Hot Shot’s Secret 15W-40 Full Synthetic with FR3 Nano Technology provides extreme temperature protection from -40°F to 400°F+, making it ideal for units facing temperature extremes during travel.

Winter Diesel Operation Challenges

Diesel generators in cold climates require special attention—both to fuel and oil. While winter diesel formulations prevent fuel gelling, your generator engine oil type must maintain proper flow at startup. A 15W-40 synthetic oil provides the ideal balance, thin enough for cold starts yet thick enough to protect during extended operation in freezing conditions.

Natural Gas and Propane Generator Oil Types

Natural gas and propane generators burn cleaner but create different combustion byproducts that demand specialized oil formulations. Standard oils break down faster in these applications due to higher operating temperatures and unique chemical reactions.

Natural Gas Engine Oil Requirements

Premium Blue Natural Gas Engine Oil addresses the specific needs of CNG/LNG generators with:

– Enhanced thermal stability for continuous operation

– Superior oxidation resistance preventing oil thickening

– Specialized detergents that combat high-temperature deposits

– Cold-start protection for automatic standby systems

Propane Generator Oil Benefits

Propane generators benefit significantly from Valvoline Premium Blue One Solution Gen 2, which extends drain intervals by 40% compared to conventional oils. This specialized generator engine oil type handles propane’s higher combustion temperatures while preventing the valve train wear common in gaseous-fueled engines.

Oil Viscosity Selection by Climate

Understanding viscosity ratings prevents costly mistakes that lead to hard starting or inadequate lubrication. The rating system (5W-30) breaks down as:

– First number (5): Cold temperature pumping capability

– W: Winter starting temperature rating

– Second number (30): High temperature thinning resistance

Cold Climate Oil Choices (Below Freezing)

Choose lower first numbers for better cold flow:

– 5W-30: Reliable performance down to -28°C (-18°F)

– 0W-20: Essential for extreme cold applications below -20°F

– Synthetic preferred: Provides 30% better cold start protection than conventional oils

Hot Climate Recommendations (Above 90°F)

Higher second numbers maintain protection:

– 15W-40: Diesel engines in sustained high temperatures

– 10W-30: Gasoline engines in desert conditions

– Multi-grade advantage: Flows faster than pure SAE 40 while maintaining high-temperature protection

Synthetic vs Conventional Oil Comparison

Your choice between synthetic and conventional oil affects everything from change intervals to engine longevity. Here’s the practical breakdown for generator applications:

Full Synthetic Advantages

- Extended change intervals: Up to 200 hours vs 50-100 for conventional

- Temperature extremes: Performs from -40°F to 400°F+ without viscosity breakdown

- Engine protection: 25% reduction in wear during extended testing

- Deposit prevention: Keeps engine internals cleaner over time

When Conventional Oil Works

- Light use: Occasional emergency backup operation

- Mild climates: Consistent temperatures year-round

- Budget constraints: Lower initial cost for infrequently used units

- Older generators: Some legacy models may have seal compatibility issues with synthetics

Oil Change Intervals and Maintenance

Following proper maintenance schedules prevents engine failure and maintains warranty coverage. Your generator type determines the frequency.

Portable Generator Schedule

- Standard operation: Every 50-100 hours

- Emergency use: Every 50 hours (Generac recommendation)

- Seasonal use: Change before storage and after first season use

- Severe conditions: Check before every use (Honda guidance)

Standby Generator Maintenance

- Typical operation: Every 100-200 hours

- Annual minimum: Regardless of usage

- Heavy use: Every 100 hours or annually, whichever comes first

- Harsh environments: Dust, humidity, or temperature extremes require 25-50% more frequent changes

Common Oil Selection Mistakes

Avoiding these errors saves thousands in repairs and maintains reliable operation:

Using Car Oil in Generators

While technically compatible, car oils lack small engine-specific additives generators require. The higher RPM operation and different combustion characteristics demand generator-specific formulations. Never substitute automotive oil without explicit manufacturer approval.

Ignoring Viscosity Ratings

Using 10W-30 in freezing temperatures causes hard starting and potential engine damage. Always match viscosity to your operating temperature range—Briggs & Stratton testing shows incorrect viscosity increases wear by 15% even during short operation cycles.

Overlooking API Certifications

Minimum API Service Class SJ or SL ensures adequate protection. Higher certifications (SM, SN) provide better deposit control and wear protection, especially important for generators that sit unused for months between operation cycles.

Step-by-Step Oil Change Process

Proper oil change procedure prevents contamination and ensures complete drainage. Follow these steps precisely:

- Cool completely: Hot oil causes burns and poor drainage

- Level positioning: Ensures complete drainage and accurate refill

- Drain thoroughly: Remove all old oil and contaminants

- Filter replacement: Change oil filter if your generator has one

- Refill correctly: Use exact oil type and quantity specified

- Brief operation: Run 2-3 minutes to circulate oil

- Level verification: Recheck and top up as needed

Storage Preparation

Before extended storage, drain old oil completely and refill with fresh oil. This prevents contamination and deposit formation during storage periods, ensuring reliable startup when needed.

Quality Assurance Checklist

Before purchasing oil, verify these five critical factors:

- Manufacturer approval: Check your generator manual for specific requirements

- API certification: Look for circle certifications on containers (SM or SN preferred)

- Viscosity match: Confirm temperature range compatibility

- Brand reputation: Stick with known manufacturers like Valvoline or Mobil

- Fresh stock: Check expiration dates on synthetic oils (typically 5 years)

Final Recommendations

Your generator’s oil choice directly impacts its reliability when you need it most. Start with manufacturer recommendations, then adjust based on your specific operating conditions. Synthetic oils provide the best protection for most applications, especially in extreme temperatures or extended operation scenarios.

Track your oil changes meticulously, monitor oil condition between changes, and never compromise on quality. The few dollars saved on cheap oil pale compared to a generator failure during a power outage. Your generator’s longevity and reliability depend on the generator engine oil type flowing through its engine—choose wisely and maintain it properly. When selecting your next oil, remember that the right generator engine oil type isn’t an expense; it’s insurance against power failure when every minute counts.