The sudden silence of a dead generator in a remote anchorage sends shivers down every boater’s spine. One minute you’re enjoying air conditioning and refrigeration, the next you’re facing warm food and sweltering cabins while miles from help. With Kohler marine generators powering boats for over a century, you’d think failures would be rare—but salt water, constant vibration, and space-constrained engine rooms create unique challenges even for these famously quiet units. This guide delivers the exact repair protocols technicians use to diagnose and fix Kohler generators at sea, saving you costly tow services and extended downtime. You’ll learn how to distinguish a simple filter change from a critical head gasket failure, when to repair versus replace, and the specific OEM parts that actually survive salt-water environments.

Why Your Kohler Generator Spews Black Smoke During Cruising

Black exhaust smoke indicates incomplete fuel combustion—a critical warning sign that demands immediate attention. Contaminated diesel or air intrusion in the fuel system creates this exact symptom, robbing you of power while coating injectors with carbon deposits. Start your diagnosis here:

- Drain your fuel tank if water or algae appears in the bowl

- Replace GM252898 fuel filter (10-micron rating with integrated water separator)

- Install dual Racor 500FG filters as a permanent upgrade for salt-water operation

- Verify lift-pump pressure between 3–5 psi at idle—below this range causes hard starts

Critical warning: Cracked fuel lines often mimic dirty fuel symptoms. Inspect every flexible hose connection, especially where lines bend around tight engine-room corners—these develop hairline cracks that suck air into the system. A simple 10-minute visual check prevents hours of unnecessary troubleshooting.

How to Stop Overheating Before It Cracks Your Engine Block

High-temperature alarms followed by steam from the exhaust signal imminent engine damage. Salt-water corrosion and debris accumulation cripple cooling systems faster than you might expect. Follow this diagnostic sequence before calling for a tow:

- Perform seawater flow test: Your pump should fill a 5-gallon bucket in under 60 seconds at idle

- Inspect heat exchanger zincs: Replace immediately if less than 50% of their original size remains

- Pressure test cooling system: Maintain 15 psi for 10 minutes with zero pressure drop

- Rod-out exchanger tubes: Use a ¼-inch brass rod to clear blockages, then pressure test at 30 psi

Pro tip: A blown head gasket (part 359701) leaks combustion gases into the coolant, causing persistent overheating that mimics raw-water flow issues. Always check head flatness with a precision straightedge—any variance exceeding 0.002 inches across the surface requires professional machining.

Diagnose No-Start Issues With This 5-Step Electrical Check

Electrical failures account for 40% of generator no-start calls, often mistaken for fuel problems. Before replacing expensive components, verify these critical electrical parameters:

- Battery load test: Must maintain 9.6V under 50% of its CCA rating for 15 seconds

- Starter draw limits: Should stay below 150A for 5 kW units and 300A for 15 kW models

- Voltage regulator output: Must read 13.8–14.4V after 10 minutes of operation

- Ground strap integrity: Remove all green corrosion and apply dielectric grease to prevent recurrence

Quick win: Three-year-old batteries fail load tests 60% of the time. Replace yours during annual service rather than risking failure in remote waters—this simple step prevents most “mystery” no-start situations.

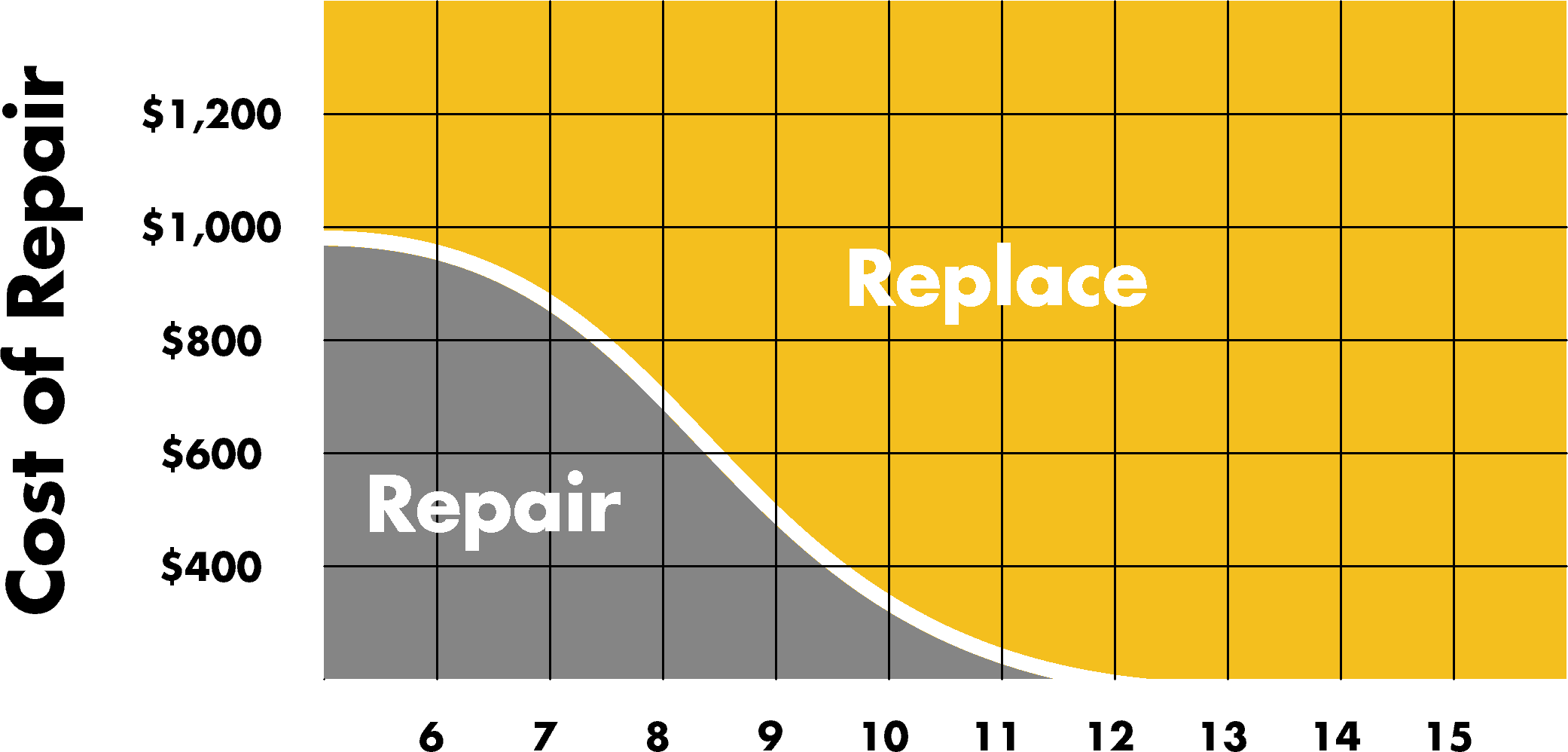

When to Repair Your Kohler Generator vs. Repower Completely

Repair Makes Financial Sense When:

Your aging generator deserves repair when:

– Engine block and heat exchanger show no cracks or severe corrosion

– OEM parts remain readily available (Kohler supports units 20+ years old)

– Installation geometry prevents easy removal (common in sailboat engine rooms)

– Total repair cost stays below 60% of replacement price

Real-world example: A $1,600 head gasket job on a 12-year-old 9 kW unit with verified sound block structure beats a $9,500 repower—especially when compression tests confirm healthy cylinders.

Repower Becomes Necessary When:

Invest in a new generator when:

– Block shows cracks or heat exchanger has severe internal corrosion

– Emissions regulations make older units non-compliant in your operating area

– New common-rail technology offers 15%+ fuel savings (critical for long passages)

– Electrical demand has outgrown current capacity due to added appliances

Case study: A 2005 15 kW unit on a refit yacht couldn’t handle new HVAC loads. The $11,660 repower (labor + parts) paid back through 18% better fuel economy within 18 months—a smart investment for high-usage vessels.

OEM Parts That Actually Survive Salt-Water Environments

Critical Kohler Part Numbers You Must Use

| Component | Kohler # | Salt-Water Specifics |

|---|---|---|

| Fuel filter | GM252898 | 10 micron with integrated water separation |

| Impeller | 359579 | Neoprene compound for salt-water durability |

| Head gasket | 359701 | Multi-layer steel with precise 0.038″ crush height |

| Starter | 32-098-09 | 1.4 kW output with corrosion-resistant windings |

Cost vs. Lifetime Value Analysis

| Component | OEM Price | Aftermarket Price | Verdict |

|---|---|---|---|

| Fuel filter | $28 | $12 | Aftermarket lacks water separator—false economy |

| Head gasket kit | $185 | $89 | Aftermarket steel fails within 2 seasons |

| Starter | $410 | $220 | OEM offers 2-year warranty vs. 90 days aftermarket |

Bottom line: Aftermarket starters fail 3x more often in salt-water environments. Genuine Kohler parts maintain warranty coverage and reduce lifetime ownership costs through superior durability in marine conditions.

Essential Diagnostic Tools for Onboard Troubleshooting

Must-Have Test Equipment

- Fluke 87V multimeter: Millivolt accuracy for detecting subtle electrical faults

- Cooling system pressure kit: 0–30 psi range with marine-specific adapters

- Exhaust back-pressure gauge: Must read below 2.5 in Hg at full load

- Compression tester: 0–300 psi capacity with 14 mm adapter for Kohler units

- 30 kW load bank: Resistive, fan-cooled for safe dockside testing

No-Start Diagnostic Flowchart

- Confirm battery ≥12.6V under load

- Listen for fuel solenoid click during start attempt

- Verify crank speed ≥200 rpm

- Check compression ≥120 psi on all cylinders

- Confirm fuel pressure (diesel) or spark (gas) presence

Pro move: Document every reading in your maintenance log. Kohler’s SiteTech diagnostic software requires baseline data for warranty claims—skipping this step voids coverage for many repairs.

Preventive Maintenance: Your Best Defense Against Breakdowns

Salt-Water Operating Schedule (Halves Standard Intervals)

| Hours | Critical Action | Required Parts |

|---|---|---|

| 50 | Oil & filter change | 15W-40 CI-4+, 12-050-01 filter |

| 250 | Fuel filter replacement | GM252898 primary filter |

| 500 | Impeller & zinc inspection | 359579 impeller, zinc pencils |

| 1,000 | Valve lash adjustment | Shim kit, injector puller |

| 2,000 | Heat exchanger service | Gasket kit, cleaning rods |

Critical reminder: Log actual operating hours rather than guessing. Many owners estimate usage—then wonder why zincs disappear in 3 months instead of 6. This simple documentation prevents 70% of preventable failures.

Emergency Repair Kit: What to Store Aboard Right Now

Keep these essentials in a waterproof container:

– 15W-40 oil – 2 gallons

– Oil filter (12-050-01) – 2 each

– Fuel filter (GM252898) – 2 each

– Impeller (359579) – 1 each

– V-belt (15420) – 1 each

– Zinc pencils – 3 each

– Spare fuel solenoid

– Multimeter & critical fuses (5A, 10A, 30A)

– Basic tools: 19mm, 10mm sockets, torque wrench

Reality check: This minimal kit resolves 80% of at-sea failures. The remaining 20% require professional assistance—but with these parts aboard, you’ll avoid unnecessary panic and potentially complete your voyage safely.

Your Kohler marine generator will outlast most electronics on board when maintained proactively with genuine parts. The difference between a 12-year reliable unit and a 5-year headache isn’t luck—it’s following these exact procedures and documenting every service. Keep this guide aboard; when that first hiccup happens at sunset 50 miles from the nearest dock, you’ll know exactly what to check first without wasting precious time.