Your diesel generator installation determines whether backup power saves your business during an outage or becomes a $50,000 paperweight. Too many projects fail at the critical moment because installers cut corners on foundation specs or skip utility notifications. This guide extracts hard-won lessons from thousands of AJ Power installations—from farm outbuildings to London data centers—to ensure your system starts when disaster strikes. You’ll learn precise concrete tolerances, fuel pipe material requirements, and the exact compliance steps that prevent 30-day project delays.

Site Selection Requirements That Prevent Costly Reworks

Choosing the wrong location triggers chain-reaction failures. Generators installed near property lines routinely violate noise ordinances, while improper drainage submerges control panels during storms. Every installation must satisfy these non-negotiable criteria before permits get approved.

Flat Surface Specifications for Critical Oil Drainage

Your foundation must maintain oil pressure within 0.5 PSI of specifications during operation. Pour a reinforced concrete pad extending 150mm beyond the generator footprint with these exact tolerances: maximum 2mm deviation per meter for proper oil circulation, 1:100 slope away from the unit to prevent water pooling, and 2-meter clearance on all sides for fuel truck access. Verify weight capacity against GA drawings—roof installations require structural engineers to certify point-loading before crane mobilization.

Noise and Emission Control for Urban Sites

City installations demand precision noise mapping. Measure baseline decibel levels at property lines during quiet hours (typically 10 PM–7 AM) to establish compliance margins. Position exhaust outlets perpendicular to neighboring windows and away from prevailing winds—exhaust recirculation into cooling intakes causes immediate overheating. For rooftop units, install spring isolators rated for 2.5× static deflection to prevent vibration transmission through building structures.

Regulatory Compliance Steps That Avoid Project Shutdowns

Skipping utility notifications voids warranties and triggers fines. Contact your electricity provider 30 days pre-installation to finalize anti-islanding protection specs and grid synchronization requirements. Local councils enforce strict fuel storage rules: bulk tanks under 3,500 liters require secondary containment at 110% capacity, while larger systems need double-walled piping with leak detection. Always secure permits before breaking ground—retroactive approvals cost 3× more and cause 45+ day delays.

Foundation and Mounting Systems for Vibration Elimination

Concrete Plinth Construction with Zero Tolerance

Embed J-bolts during the pour using AJ Power’s GA drawing templates—field drilling creates weak points that crack under vibration. Cure concrete for 7 full days before generator placement, and verify these critical dimensions: anchor bolt spacing (±2mm tolerance), fuel line entry points, and cable tray positions. For basement installations, confirm point-loading data with structural engineers to prevent floor slab fractures.

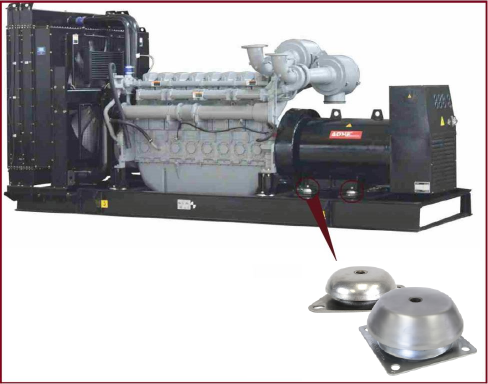

Vibration Isolation Techniques for Elevated Sets

Ground-level units require 25mm rubber isolation pads under the skid frame. Elevated installations demand spring isolators sized for 2.5× static deflection—undersized units transfer vibration to building structures causing sensor failures. Always connect fuel and exhaust lines with flexible sections; rigid piping transmits engine vibration directly into building infrastructure.

Fuel System Installation Preventing Contamination and Fire

Base Tank Integration with Warranty Protection

Most AJ Power sets include skid-mounted tanks for 8–12 hours of runtime at 75% load. Never field-weld tank brackets—this voids manufacturer warranties. Install electronic level sensors at 25% (trigger transfer pump) and 90% (stop pump) capacity points. Use only EN590 diesel or HVO (Hydrotreated Vegetable Oil), though HVO costs 15% more. Add biocide quarterly for standby systems to prevent microbial growth.

Bulk Storage Design for Safety and Compliance

Position day tanks minimum 3 meters from the generator to reduce fire risk. Use black-iron pipe (never galvanized) with positive slope back to the tank—trapped fuel causes airlocks during priming. Size transfer pumps for 2× engine fuel consumption rate; undersized pumps starve engines during high-load transitions. For systems over 500 kVA, install fuel coolers to maintain tank temperature ≤55°C and prevent power derating.

Exhaust and Ventilation Setup Avoiding Overheating Failures

Exhaust Routing Rules for Optimal Back-Pressure

Keep exhaust runs under 10 meters to minimize back-pressure. Calculate total system restriction including silencer pressure drop (from engine data sheets), pipe friction losses, and elbow restrictions (each bend equals 1.5 meters of straight pipe). Hospital-grade silencers reduce noise by 15–20 dB(A) versus standard units in noise-sensitive zones. Critical rule: Never connect multiple generators to common stacks—exhaust backflow destroys turbochargers.

Cooling Air Requirements for Extreme Climates

Size intake/exhaust louvers for 110% of radiator face area after accounting for blade blockage. In ambient temperatures above 40°C, add forced ventilation fans providing 5 air changes per minute. Install motorized louvers that close when the generator stops to prevent cold air infiltration in winter. Verify directional airflow: rear (alternator) → engine → radiator → outdoor discharge.

Electrical Integration Process Ensuring Clean Power Transfer

Cable Sizing Calculations Preventing Voltage Drop

Size conductors for 100% of standby kVA rating at 0.8 power factor. Increase cable size when voltage drop exceeds 3%—common on runs over 30 meters. Separate power and control cables by 300mm minimum using metallic barriers to prevent electromagnetic interference. For trench installations: 750mm depth with sand bedding and warning tape; overhead routes require 5.5-meter clearance for vehicle access.

Transfer Switch Selection for Critical Applications

Manual Transfer Switches (MTS) work for residential use with single-phase 240V systems and non-critical loads. Automatic Transfer Switches (ATS) are mandatory for commercial sites, life safety systems, and unattended operation. Program critical time delays: 10 seconds for start delay (prevents nuisance transfers) and 5 minutes for return delay (avoids re-transfer during utility fluctuations).

Testing and Commissioning Protocol Validating System Reliability

Pre-Start Checklist Before First Ignition

Complete this mechanical verification before starting:

– Torque all foundation bolts to specification

– Verify oil level at full mark (overfilling causes crankcase pressure issues)

– Prime fuel system until clear fuel flows from bleed screws

– Check coolant levels in radiator and expansion tank

Load Bank Testing Meeting ISO 8528-5 Standards

Apply 0–100% load in 25% increments while monitoring:

– Voltage regulation (±1% target)

– Frequency stability (±0.25 Hz)

– Exhaust temperature rise rate

– Fuel consumption verification

Document results in your commissioning report—this is required for warranty activation. AJ Power includes factory witness testing at no extra charge.

Noise Control Strategies for Residential Zone Compliance

-1000x1000.jpg)

Acoustic Enclosure Selection Based on dB Limits

Standard canopies reduce noise to 65–75 dB(A) at 7 meters. For residential areas requiring ≤55 dB(A), upgrade to super-silent designs with additional absorptive lining. Always position enclosures with 1-meter clearance on all sides for maintenance access—cramped installations overheat during load testing.

Architectural Solutions for Persistent Noise Complaints

Build masonry walls with minimum 20 kg/m² surface mass and absorptive inner linings for 15–20 dB(A) additional attenuation. Design walls 2 meters taller than the generator exhaust to block line-of-sight noise paths. Combine with hospital-grade silencers for maximum noise reduction in sensitive locations.

Maintenance Program Setup Avoiding Surprise Failures

Daily Inspections for Early Problem Detection

Assign operators to check:

– Visual leak indicators (fuel, oil, coolant)

– Battery charger status lights

– Fuel level readings

– Warning light status on control panel

Scheduled Testing Timelines for Reliability

- Weekly: 10-minute no-load exercise

- Monthly: 30-minute loaded test

- Quarterly: Full-load step test with 0–100% load change

- Annually: Oil change, coolant test, fuel polishing

Program automatic exerciser clocks on ATS systems to enforce testing—80% of standby generator failures occur due to neglected exercise routines.

Cost Planning Framework Preventing Budget Overruns

Budget Allocation Based on Actual Project Data

Typical project costs break down as:

– Generator set: 45–55% of total

– Installation and commissioning: 35–45%

– Contingency and approvals: 5–10%

Hidden costs that derail projects:

– Council permit fees (often 5–7% of budget)

– Fuel storage compliance upgrades

– Electrical switchgear modifications

– Acoustic consultant reports

Procurement Timeline Avoiding Delivery Delays

Order generators 8–12 weeks before required date. Coordinate delivery with crane availability—weather delays add days to urban projects. Factor in 2 weeks for factory witness testing to catch manufacturing defects pre-shipment.

Installation Success Checklist Before Final Sign-Off

Verify these 6 critical items before declaring completion:

– All permits approved and displayed on-site

– Utility interconnection fully tested

– Load bank test passed with documentation

– Operator training completed for daily checks

– Maintenance contracts activated

– Spare parts inventory (filters, belts, fuses) stocked onsite

Your diesel generator installation sets the stage for decades of reliable operation. Skip any step, and you risk catastrophic failure when power matters most. Schedule commissioning 2–3 weeks before critical need dates—rushed installations rarely survive their first real outage. For complex projects, leverage AJ Power’s engineering support at info@ajpower.net to avoid costly field modifications.