Your generator sits quietly outside until the moment you need it most—then it becomes your lifeline during power outages. But without proper maintenance, that reliable backup can fail when you need it most, leaving you in the dark with spoiled food, no heat, and potentially thousands in damages. The good news? Most generator failures are entirely preventable with a systematic electric generator maintenance approach that takes just a few hours each year.

This guide walks you through everything you need to know to keep your generator ready for action, from simple weekly checks to professional servicing requirements. Whether you have a portable unit or whole-home standby system, these maintenance practices will extend your generator’s life from years to decades while ensuring it starts reliably every time.

Never Miss These Critical Generator Service Intervals

Your generator’s lifespan depends on hitting these exact maintenance milestones. Most homeowners overlook the first oil change at 30 runtime hours for new generators, causing premature wear that shows up years later. Stick to this precise schedule to avoid catastrophic failures when you need power most.

For standard operation, change your generator’s oil every 50-100 runtime hours or annually—whichever comes first. Ignoring this leads to thickened oil that fails to lubricate properly during extended outages. Spark plugs and air filters need service every 100-200 hours or seasonally. Critical warning: Battery replacement is non-negotiable every 24-36 months regardless of usage—old batteries cause 30% of generator non-starts during emergencies.

Track every service in a dedicated logbook with hour-meter readings, part numbers, and detected issues. This documentation proves invaluable when troubleshooting or filing warranty claims after a major storm.

How to Properly Exercise Your Generator Weekly

Run permanently installed units 20-40 minutes under actual load each week to lubricate engine components and maintain battery charge. Portable units need 15-30 minutes monthly if not used regularly. Don’t just let it idle—connect essential appliances like refrigerators or freezers to simulate real-world conditions.

During exercise runs, verify smooth starting within the manufacturer’s specified crank attempts. Listen for unusual vibrations or knocking sounds that indicate developing problems. Check voltage output stability under load with a multimeter—fluctuations beyond 5% signal potential issues needing professional attention.

Fix Oil-Related Engine Failures Before They Happen

Low oil causes immediate engine seizure—the number one preventable generator killer. Follow this exact oil change procedure to protect your investment:

- Warm the engine for 5 minutes to thin the oil for complete drainage

- Position an approved container under the drain plug

- Remove the drain plug and let oil drain completely

- Replace the oil filter to prevent clogging that reduces oil volume

- Add manufacturer-specified oil (most units use 5W-30 synthetic)

- Run the engine for 1 minute to circulate oil, then recheck the level

Never skip oil filter replacement—a clogged filter drastically reduces oil volume, leading to catastrophic engine damage during extended outages. Check oil levels before every exercise run, especially if you live in areas with frequent power disruptions.

Prevent Battery Failures That Leave You Powerless

30% of generator failures during emergencies stem from dead batteries. Protect yourself with this battery maintenance protocol:

- Maintain 12.4-12.6 volts using a trickle charger during storage periods

- Inspect terminals monthly for white, crusty corrosion buildup

- Clean terminals with a wire brush and apply dielectric grease when needed

- Disconnect the negative terminal first during extended non-use periods

- Store spare batteries in climate-controlled areas if you live in cold regions

Test your battery voltage monthly—anything below 12.4 volts indicates weakening capacity. In freezing temperatures, weak batteries fail completely, so verify cold-weather performance before winter storm season arrives.

Essential Component Service You Can Do Yourself

How to Clean or Replace Your Generator Air Filter

Inspect your air filter annually or every 100-200 hours of operation. Dirty filters choke engine performance and increase fuel consumption by up to 15%. For foam filters, clean with compressed air blown from the inside out. Paper filters must be replaced immediately when visibly dirty—never attempt to clean them.

Ensure proper seating after cleaning or replacement to prevent dirt from entering combustion chambers. A poorly seated filter causes accelerated engine wear that leads to expensive repairs down the line.

Spark Plug Service That Guarantees Cold-Weather Starts

Annual spark plug inspection prevents starting failures when temperatures drop. Remove the spark plug and check for carbon buildup or electrode erosion. Replace immediately if electrodes are worn or the insulator is cracked—don’t risk being without power during a winter storm.

Gap new plugs to your manufacturer’s specifications using a feeler gauge. Properly gapped plugs create stronger sparks for reliable starting in freezing temperatures, while incorrect gaps cause misfires and hard starting.

Know When to Call a Professional Generator Technician

Critical Maintenance Tasks Requiring Expert Service

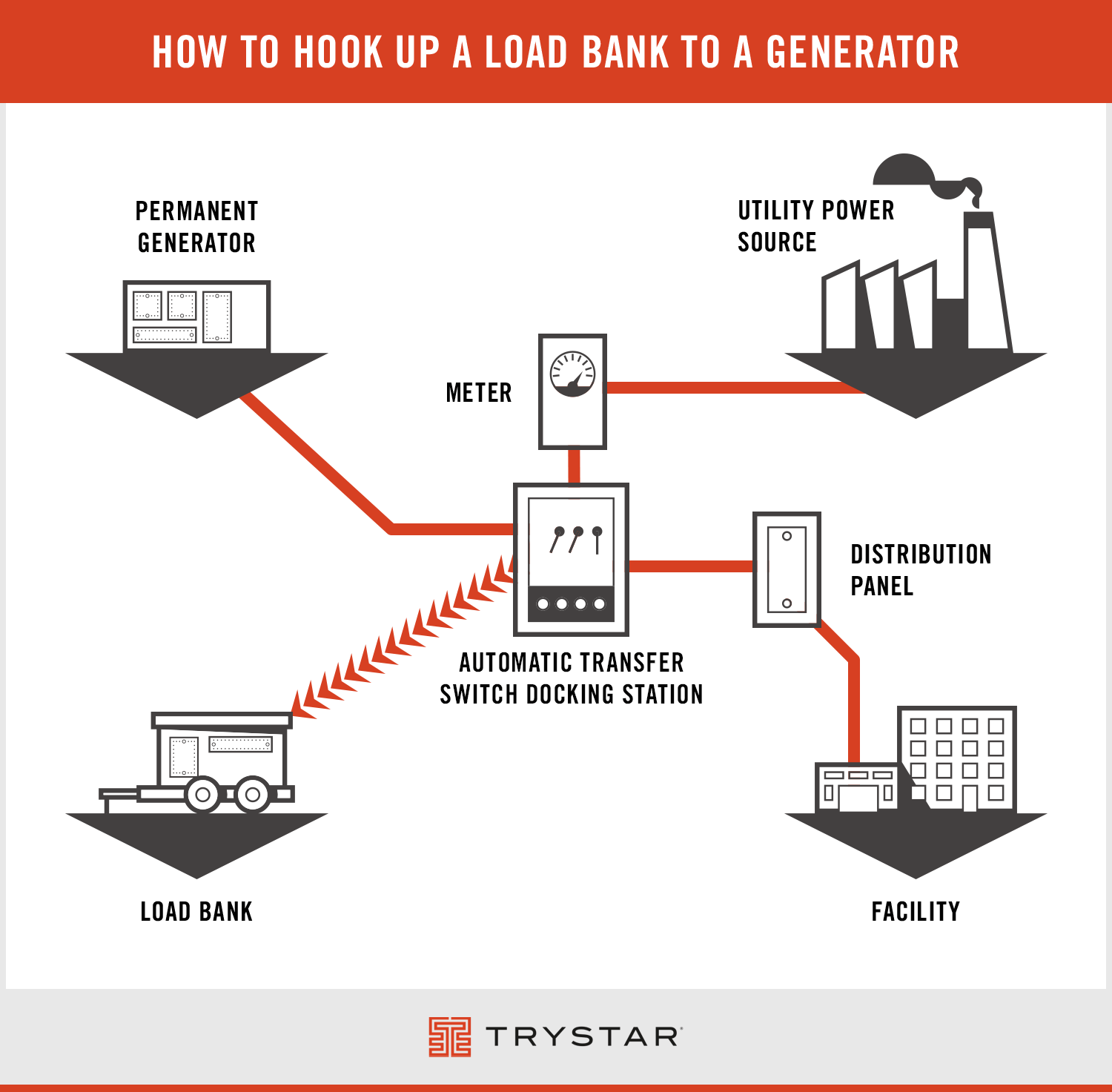

While many maintenance tasks are DIY-friendly, certain procedures demand professional expertise. Load bank testing simulates full electrical load to verify performance under real-world conditions—a service most homeowners can’t perform safely. Fuel system pressure testing and electrical connection tightening require specialized equipment to prevent dangerous malfunctions.

Modern generators with digital controls need periodic software updates that only certified technicians can perform. Warranty compliance servicing must be documented by authorized dealers to maintain coverage. If your generator shows unusual noises or persistent startup issues, professional diagnosis prevents minor problems from becoming major repairs.

Service contracts deliver predictable maintenance costs, priority response during widespread outages, and warranty preservation while giving you access to specialized diagnostic equipment. For whole-home systems, this investment pays for itself when the grid goes down during hurricane season.

Generator Safety Protocols That Could Save Your Life

Non-Negotiable Pre-Service Safety Steps

Never operate generators indoors or in any enclosed space—carbon monoxide poisoning kills more people annually than generator fires. Ensure working carbon monoxide detectors are installed throughout your home. Allow the engine to cool 15-20 minutes before touching hot components during maintenance.

Use non-flammable degreasers for cleaning procedures near fuel systems. Keep an ABC fire extinguisher within 10 feet during all service activities. Critical warning: Always store your generator with an empty fuel tank for periods exceeding one month to prevent dangerous vapor buildup.

Spot Generator Problems Before They Leave You Powerless

The 2-Minute Weekly Visual Inspection Checklist

Prevent major failures with this quick weekly check:

– Look for oil or fuel leaks on the ground beneath your unit

– Check for corroded electrical connections or terminals

– Ensure debris isn’t blocking cooling air intake vents

– Watch for signs of animal nesting (mice, squirrels, insects)

– Inspect belts and hoses for unusual wear or cracks

During operation, listen for smooth starting within the manufacturer’s specified crank attempts. Verify stable voltage output under actual load conditions—use a multimeter to confirm readings stay within 5% of nominal voltage. Any unusual vibrations or knocking sounds indicate developing problems needing immediate attention.

Seasonal Generator Prep That Prevents Storm Failures

Before winter arrives, test your generator’s cold-weather starting capability and verify battery performance in low temperatures. Check block heater operation if your unit is equipped. For diesel generators, ensure fuel additives prevent gelling in freezing conditions.

Prior to hurricane season, verify increased load capacity for air conditioning systems and check cooling system efficiency in high heat conditions. Inspect the area around your unit for storm debris clearance—fallen branches can block ventilation during critical power outages.

Why Generator Maintenance Pays for Itself

Preventative maintenance extends generator lifespan by 50-100%, making the investment highly worthwhile. Professional service costs $150-400 annually, while emergency repairs without maintenance can reach $1,000-5,000. Complete generator replacement ranges from $3,000-15,000+ depending on capacity.

ROI calculation: Spending $300 annually on maintenance can prevent $5,000+ in emergency repairs, delivering 300-1000% return on investment over your generator’s lifespan. The few hours you invest annually will save you from potentially devastating failures during critical outages.

Your generator is only as reliable as your maintenance program. Commit to the simple schedule outlined above, and you’ll have confidence that your backup power will start when you need it most. Start with weekly visual checks and monthly exercise runs, then expand into more detailed service as you become comfortable. The peace of mind you gain is worth every minute invested in proper electric generator maintenance.