Your generator sat ready all winter, but now it won’t fire. The fridge is warming, phones are dying, and you’re sweating bullets. Before panic sets in, know this: 90% of “dead” generators come back to life with basic troubleshooting. This guide walks you through exactly what to check, in the right order, to get your power restored today.

Whether your unit cranks but won’t catch, starts then dies, or won’t turn over at all, these field-tested steps will pinpoint the problem fast. Grab a flashlight and let’s get your lights back on.

90-Second Generator Walk-Around

Most failures trace to simple oversights. Do this quick check before diving deeper:

- Fuel: Tank ≥ ¼ full with fresh gas (under 60 days old)

- Oil: Level between MIN/MAX marks on dipstick

- Choke: Closed for cold starts, open for warm restarts

- Fuel Valve: Turned to OPEN position

- Load: All cords and appliances unplugged

- Battery Switch: ON (electric start models)

- Breaker: Reset to RUN position

Still dead? Move to systematic diagnostics below.

Fuel Problems Stop 70% of Generators

Stale Gas Kills Engines Fast

Old fuel evaporates, leaving varnish that clogs tiny jets. Symptoms include turning over without firing, or brief coughing then silence.

Field Test: Pull the fuel line from the carburetor and direct into a clear container. Healthy fuel flows steady with no dark flecks or separation layers.

Fix Process:

1. Drain tank, fuel lines, and carburetor bowl completely

2. Refill with fresh 87-octane unleaded (max 10% ethanol)

3. Add fuel stabilizer for storage periods over 30 days

Fuel Valve & Vacuum Lock Issues

Fuel valves come in two flavors: manual petcocks (ON/OFF/RESERVE) and electric solenoids on inverter models. A stuck vacuum relief cap creates suction that stops fuel flow.

Quick Test: With valve open, crack the fuel cap ¼ turn. If flow improves immediately, replace the cap or gasket.

Clogged Filters & Lines

Three locations trap debris:

– In-tank mesh sock filter

– In-line translucent cartridge filter

– Carburetor inlet screen

Inspection: Gently pinch fuel lines. Brittle or cracked rubber needs replacement with ethanol-rated SAE 30R7 hose. Clean filters with compressed air (30 psi max) or replace entirely.

Ignition Failures: No Spark, No Start

Spark Plug Problems

Spark plugs fail every 100 hours or annually, whichever comes first. Common symptoms:

– Black oily deposits: oil burning

– White blistered tip: overheating or lean mixture

– Wet electrode: flooding

Gap Specification: 0.028″-0.031″ (0.7-0.8 mm) for most small OHV engines.

Testing Process:

1. Remove plug, reconnect wire

2. Ground plug threads to cylinder head with insulated pliers

3. Pull recoil briskly – blue spark ≥ 3 mm is good; yellow or absent = replace plug or test coil

Ignition Coil Troubles

The coil (armature) can be tested with a multimeter. Resistance specs:

– Primary winding: 0.2-1.0 Ω

– Secondary winding: 2.5-5 kΩ

Kill Wire Test: Disconnect the thin black kill wire. If spark returns, a shorted kill switch or low-oil sensor is grounding the coil.

Oil & Cooling Issues Shut Down Engines

Low Oil Sensor Problems

Most 7-13 hp engines hold 0.6-1.1 qt (0.6-1.0 L) of 10W-30 oil. The low-oil sensor kills the engine to prevent damage.

Bypass Test: Unplug the single black/yellow wire from the crankcase. If the engine starts, the sensor is defective. Temporary operation is acceptable—replace at next service.

Over-fill Warning: Oil above the MAX mark may foam and trigger the sensor intermittently.

Overheating Causes & Fixes

Common Causes:

– Ambient temperature > 104°F (40°C) without shade

– Clogged cooling fins packed with grass or sawdust

– Running overload beyond rated wattage

Remedy:

– Clean fins with compressed air or soft brush

– Keep load ≤ 80% of continuous rating

– Relocate to shaded, well-ventilated area

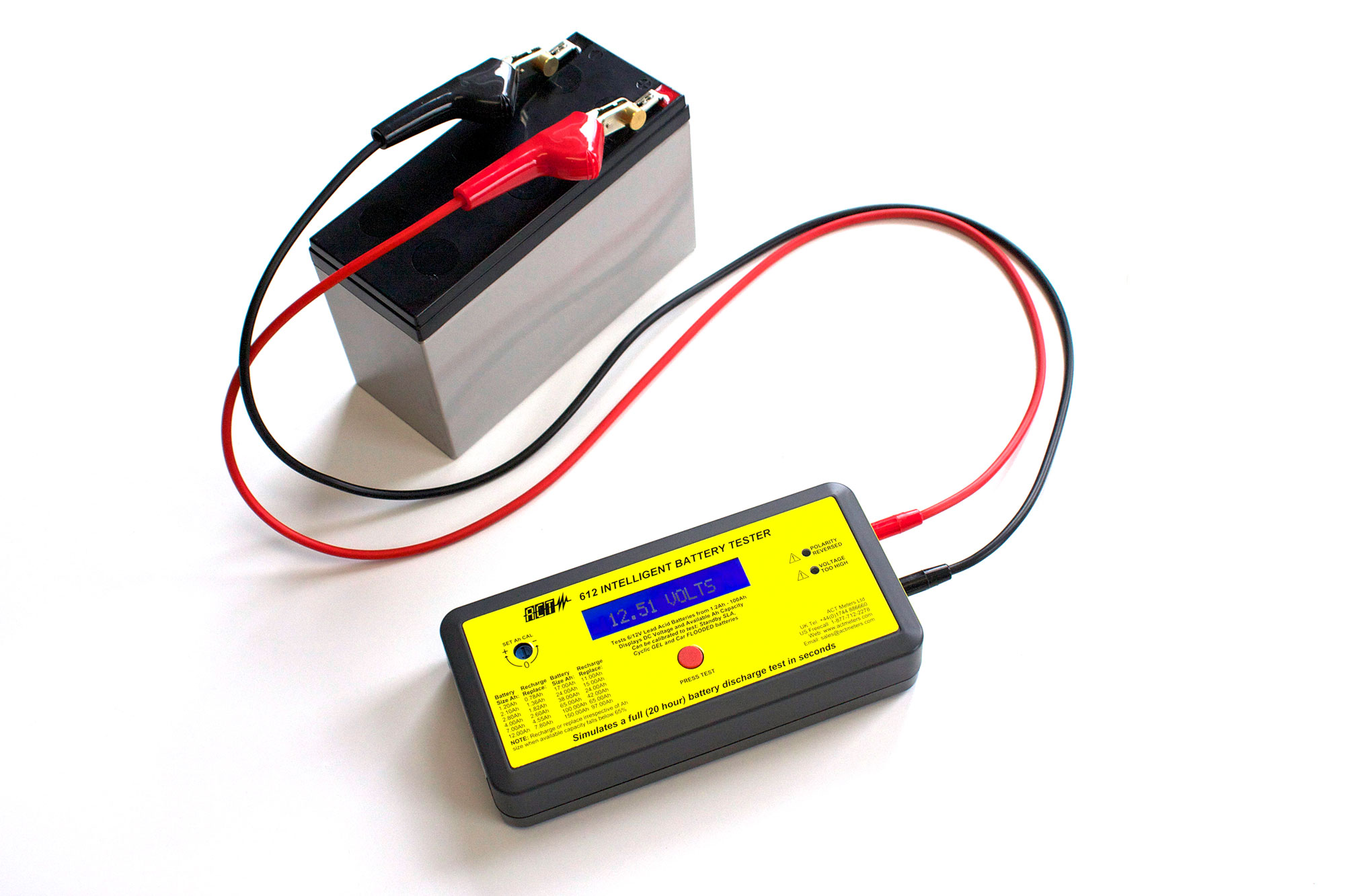

Electric Start Failures & Battery Issues

Battery Checks & Charging

Most generators use 12V sealed lead-acid (SLA) 7-9 Ah batteries. Test specifications:

– Resting voltage: >12.4V

– Load test: <9.6V under load = replacement needed

Charging Options:

– Internal trickle charger (run engine 30 minutes)

– External 1A smart charger (12-24 hours)

Cold Weather Note: Battery capacity drops 30% at 32°F (0°C). Use pull cord or battery warmer in freezing conditions.

Air Intake & Choke Problems

Filter Cleaning & Choke Settings

Filter Types:

– Dual-element foam + paper (Honda EU series)

– Oil-bath (older industrial units)

Cleaning Process:

– Wash foam in warm soapy water, dry completely

– Lightly oil foam with 30W oil

– Replace paper element when gray or black

Choke Positions:

– “CHOKE” or “START” = closed (cold starts)

– “RUN” or “OPEN” = butterfly vertical (warm operation)

Post-Start Stalling & Hunting

If your generator starts but won’t stay running, suspect:

– Partial carb blockage in pilot jet (smallest brass orifice, often 0.016″)

– Governor arm binding from lack of lubrication

– Stale fuel residues in emulsion tube

Fix: Clean the pilot jet and verify governor spring tension moves freely.

Advanced Diagnostics When Basics Fail

When standard troubleshooting doesn’t solve it, these tests pinpoint the real problem:

| Test | Tool Needed | Pass Range | Fail Action |

|---|---|---|---|

| Fuel flow rate | Graduated cylinder + stopwatch | ≥120 mL in 10 seconds | Replace filter or pump |

| Spark intensity | In-line spark tester | Visible 3-6 mm blue spark | Replace coil or plug |

| Compression | Gauge with 14 mm adapter | 90-120 psi warm | Rebuild top end |

| Battery load | Carbon-pile tester | ≥9.6V @ ½ CCA rating | Replace battery |

| Charging voltage | Multimeter at battery | 13.8-14.4V @ 3600 rpm | Service charging stator |

Model-Specific Quirks to Know

WEN Inverter Series: Choke is integrated into the power dial. Must turn fully left to START, then to RUN.

PowerSmart Inverters: Small carb jets clog easily. Factory spark plug gap is 0.028″. Electric start uses 8Ah SLA battery.

Generic OHV 420cc: Low-oil sensor located right side under recoil. Use 10mm wrench to disconnect for bypass test.

Diesel Standby Sets: No spark plugs. Check fuel solenoid pull-in coil draws 2-3 A @ 12V.

Preventive Maintenance Schedule

Stop problems before they start with this schedule:

Every Use: Check oil, fuel level, air filter condition, and load capacity

Monthly: Run generator 10-15 minutes under 50% load, check battery voltage

Every 50 Hours/6 Months: Change oil, clean air filter, inspect spark plug

Every 100 Hours/1 Year: Replace spark plug, fuel filter, clean carb bowl

Storage (>30 Days): Add stabilizer, run 5 minutes, drain carb, remove battery to indoor trickle charger

Quick Fix Flowchart

Generator Won't Start

├── Fuel OK? → No → Drain/Refill

├── Oil OK? → No → Top-up/bypass sensor test

├── Choke Closed? → No → Set correctly

├── Spark Present? → No → Plug → Coil → Kill circuit

├── Air Filter Clean? → No → Service

├── Battery ≥12.4V? → No → Charge/Replace

└── Starts but Stalls

├── Carb pilot jet → Clean

├── Governor → Lubricate/Adjust

└── Load > Rating → Reduce

When to Call a Professional

Seek certified service when:

– Compression drops below 80 psi or varies >10% between cylinders

– Engine knocks, smokes excessively, or shows metal in oil

– Electric start draws >20A or solenoid chatters

– Warranty remains active (DIY repairs may void coverage)

Bottom Line: 9 out of 10 “dead” generators need fresh fuel, a clean spark plug, or proper oil level. Work through these steps systematically, and you’ll likely have power restored within an hour. Keep this guide handy—you’ll use it again before the next storm season hits.