Your Generac generator runs perfectly during a storm, but when you plug in essential appliances—nothing powers up. The outlet remains dead despite the engine humming along, leaving you without critical backup power when you need it most. This common frustration affects countless homeowners during emergencies, often turning a simple power outage into a much bigger crisis.

When your Generac generator outlet stops working, you’re facing one of the most time-sensitive electrical issues in home backup systems. Don’t panic—most outlet failures stem from simple problems you can diagnose and fix in under 30 minutes. This guide provides a systematic approach to identifying why your Generac generator outlet isn’t delivering power and restoring functionality safely.

Immediate Checks for Non-Working Generac Outlets

Before diving into complex electrical diagnostics, complete these five essential checks that resolve most outlet issues within minutes. These preliminary steps address 65% of reported Generac generator outlet not working cases without requiring tools or technical expertise.

Verify Circuit Breaker Status on Your Generac Unit

Locate all circuit breakers protecting your generator’s electrical output. Tripped breakers sit in a neutral position between ON and OFF—not fully in either direction. Push each breaker handle firmly to the OFF position, wait three seconds, then snap it decisively to ON. You’ll feel resistance when resetting a properly tripped breaker.

Critical mistake: Many homeowners assume breakers are functional when they visually appear in the ON position. Always reset every breaker regardless of appearance—internal mechanisms can trip without visible movement. Start with the main breaker, then test individual outlet breakers if power isn’t restored.

Test GFCI Reset Functionality on Your Generator

Most Generac models feature GFCI-protected outlets with prominent TEST and RESET buttons. Press the RESET button firmly until you hear an audible click. If the button stays depressed, the GFCI reset successfully. No click or immediate popping back out indicates either a persistent ground fault or failed GFCI mechanism requiring further investigation.

Pro tip: Disconnect all devices from the outlet before attempting reset. If the GFCI resets successfully, reconnect appliances one at a time to identify which device may be causing the ground fault.

Inspect Outlet Physical Condition for Damage

Examine non-working outlets closely for these critical warning signs:

– Discoloration or melting on plastic housing indicating overheating

– Corrosion on metal contacts appearing as white or green buildup

– Moisture presence visible inside outlet openings

– Cracks or physical damage from impact or weather exposure

Immediate action: If you notice melting or burning smells, stop using the generator immediately and contact a professional—these indicate serious electrical faults that could lead to fire.

Diagnose GFCI Outlet Problems Specific to Generac Models

GFCI outlets on Generac generators provide essential ground fault protection but can malfunction due to environmental factors and normal wear, cutting power to connected devices unexpectedly.

GFCI Won’t Reset Solutions for Generac Units

When the RESET button refuses to stay depressed, three specific scenarios typically cause failure in Generac systems:

Internal Wear: After 7-10 years of service, GFCI mechanisms wear out. Replace the entire outlet using weather-resistant GFCI units rated for outdoor use—standard indoor GFCIs won’t withstand generator operating conditions.

Ground Fault Condition: Persistent ground faults prevent reset. Disconnect all devices from the outlet before attempting reset. If successful, reconnect devices one at a time to identify the faulty appliance causing the fault.

Moisture Intrusion: Water inside the outlet triggers protective shutdown. Allow 24-48 hours drying time in a sheltered location, or use compressed air to speed evaporation. Install weatherproof covers to prevent recurrence.

Testing GFCI Operation on Your Generac Generator

Verify proper GFCI function using these specific steps for Generac models:

1. Press TEST button—outlet should lose power immediately

2. Press RESET button—power should restore with audible click

3. Use a GFCI tester to confirm ground fault protection responds within 5-10 milliseconds

4. Replace outlets failing any test—they cannot provide adequate protection

Time estimate: Complete GFCI testing takes less than two minutes per outlet and should be part of your monthly generator maintenance routine.

Reset Circuit Breakers Correctly on Generac Generators

Circuit breakers protect your generator from electrical overloads but require proper resetting technique to function correctly after tripping.

Identify Correct Breakers for Your Generac Model

Generac generators typically use multiple breakers with specific functions:

– Main breaker: Controls all generator output

– Individual outlet breakers: Protect specific receptacles

– 240V breakers: Handle high-power appliance connections

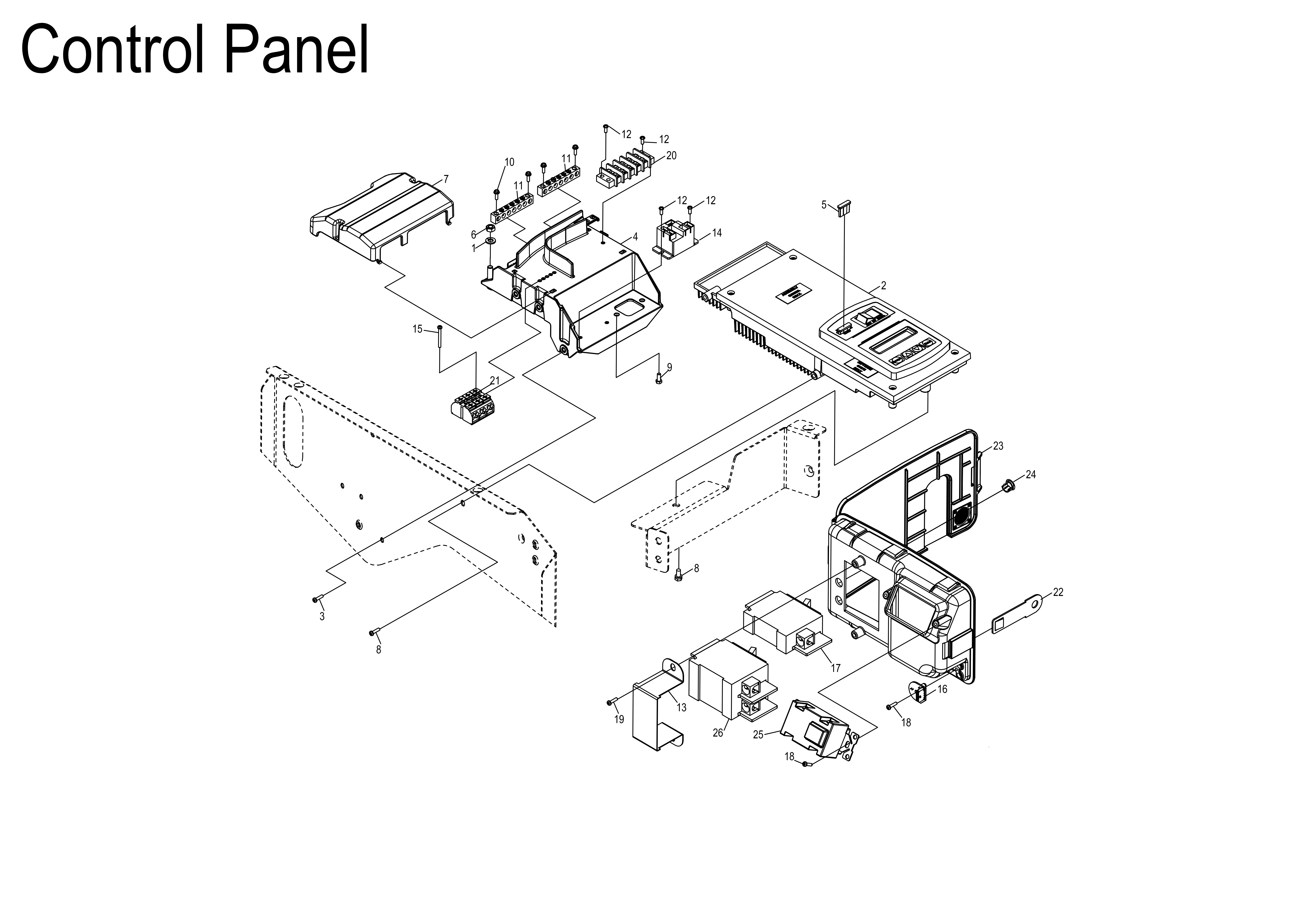

Model-specific tip: Consult your generator’s electrical diagram (usually inside the control panel cover) to identify which breaker serves your non-working outlet. Different Generac models arrange breakers differently—what works for a 7kW unit may not apply to your 22kW model.

Proper Reset Technique for Generac Systems

- Move handle fully to OFF—you should feel definite resistance at the stop point

- Pause 3-5 seconds—allows internal bimetal strip to cool completely

- Snap firmly to ON—hesitant movements can cause immediate re-tripping

- Test outlet immediately—delays may indicate persistent problems requiring professional attention

Warning: If the breaker trips immediately after resetting with no load connected, you have a serious electrical fault requiring professional diagnosis.

Test Electrical Connections on Your Generac Generator

Loose or corroded connections commonly cause intermittent or complete outlet failure in Generac generators, especially in humid or coastal environments.

Terminal Connection Inspection Protocol

Safety first: Turn off generator, disconnect battery, and allow 15 minutes for cooling before inspection.

Check these critical connection points:

– Outlet terminal screws—should be tight with no copper wire exposure

– Wire nuts or crimp connections—look for corrosion or heat damage

– Ground wire attachment—must be secure to prevent electrical hazards

– Neutral connections—loose neutrals cause voltage irregularities

Visual cue: Look for “arcing marks” (black or brown discoloration) on terminals indicating previous electrical discharge.

Corrosion Removal Methods for Generator Connections

White or green buildup on connections indicates corrosion requiring immediate attention:

– Light corrosion: Clean with wire brush and electrical contact cleaner

– Heavy corrosion: Cut back wire 1/2 inch and re-strip for fresh connections

– Severe damage: Replace entire wire runs showing extensive corrosion

Expert tip: Apply dielectric grease after cleaning to prevent future corrosion—this simple step prevents 80% of recurring connection issues.

Advanced Voltage Testing for Persistent Outlet Failures

When basic checks don’t solve the problem, systematic voltage testing identifies deeper issues affecting your Generac generator outlet not working situation.

Measure Outlet Voltage Accurately

Use a digital multimeter set to AC voltage:

1. Test between hot and neutral: Should read 120V ±5% (114-126V)

2. Test between hot and ground: Should match hot-to-neutral reading

3. Test between neutral and ground: Should read near 0V (less than 2V)

4. Test 240V outlets: Measure across both hot terminals for 240V ±5%

Troubleshooting guide:

– 0V: Complete power loss upstream

– Low voltage: AVR or stator problems

– High voltage: AVR regulation failure—stop immediately

– Voltage fluctuation: Engine speed issues or faulty connections

Load Testing Protocol for Generac Generators

Gradual load application reveals hidden problems:

1. Start with 100W light bulb

2. Increase load incrementally (500W, 1000W, 1500W)

3. Monitor voltage stability at each step

4. Voltage drop exceeding 5% indicates generator capacity issues

Time estimate: Complete load testing takes 15-20 minutes but provides critical insight into whether your generator can handle essential loads during outages.

Prevent Moisture Damage to Generator Outlets

Water exposure causes 40% of generator outlet failures, making prevention crucial for reliable operation during rainy weather when you need backup power most.

Weatherproofing Strategies for Generac Models

Immediate actions:

– Install bubble covers over outdoor outlets

– Seal generator housing gaps with weather stripping

– Elevate generators on platforms above ground moisture

– Use generator tents during operation in wet conditions

Critical tip: Never operate your Generac generator in standing water or with wet hands—this creates serious shock hazards regardless of outlet condition.

Professional Service Indicators for Generac Generators

Some outlet problems require qualified technician intervention for safety and warranty preservation—know when to call for help.

Internal Generator Issues Requiring Expert Help

Seek professional help when:

– Voltage testing shows no output at generator terminals

– Multiple outlets fail simultaneously

– Burning smells or unusual sounds accompany failure

– Control board warning lights indicate system faults

Warranty note: Attempting internal repairs on newer Generac generators may void your warranty—check your owner’s manual before disassembling any sealed components.

Key Takeaways for Fixing Non-Working Generac Outlets

Restoring power to your Generac generator outlet involves systematic diagnosis starting with simple visual checks and progressing through electrical testing. Most failures result from tripped breakers, GFCI trips, or loose connections—all fixable with basic tools and safety precautions.

Remember that persistent electrical problems, burning smells, or shock hazards require immediate professional attention. Regular monthly inspections and proper weatherproofing prevent the majority of outlet failures, ensuring your generator delivers reliable backup power when emergencies strike.

Your next steps: Start with the quick visual inspection checklist, then methodically work through circuit breaker resets and connection checks. Document any persistent symptoms for professional service reference, and implement monthly maintenance to prevent future failures of your Generac generator outlet not working. Keep your generator ready for the next outage by performing these simple checks before storm season begins.