Your Generac generator sputters and dies during a storm, and you’re scrambling to replace the spark plug—only to realize you’ve grabbed the wrong socket size. Installing an incompatible spark plug risks catastrophic engine damage, while guessing the thread reach could send piston fragments flying through your cylinder head. Every Generac portable generator uses 14 mm threads, but critical variations in socket size, reach, and gap settings mean a one-size-fits-all approach guarantees failure. This guide delivers exact spark plug specifications for 35+ Generac models, verified through factory service manuals and cross-referenced with industry-standard alternatives. You’ll avoid costly mistakes and get your generator running in under 15 minutes.

Why Your Generac Spark Plug Size Isn’t Universal

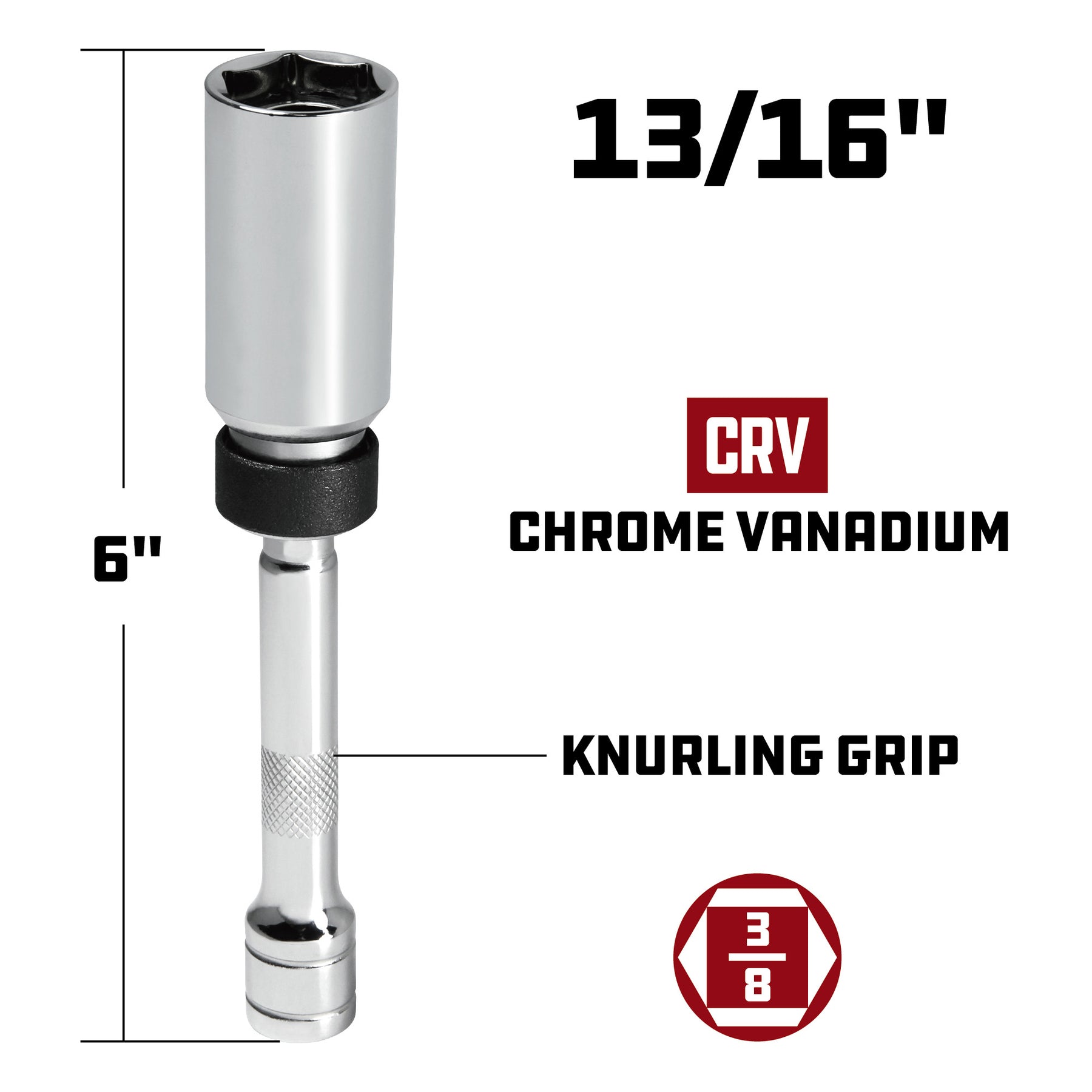

Despite sharing 14 mm threads across all portable models, Generac generators require three critical specifications that vary by series. Thread reach—the depth the plug extends into the combustion chamber—determines whether the electrode clears the piston. A 19 mm plug in a 12.7 mm-reach engine causes immediate piston contact, while the reverse creates incomplete combustion. Socket size (hex head dimension) differs between consumer and commercial units, and mismatched tools will strip plug heads. Finally, electrode gap tolerances range from 0.020″ to 0.040″, directly impacting cold-start reliability.

Key specification pitfalls:

– ❌ Using a 13/16″ socket on 5/8″ hex plugs rounds corners, making removal impossible

– ❌ Assuming all 14 mm plugs fit—even with correct threads, wrong reach destroys engines

– ❌ Skipping gap verification: factory settings drift during shipping, causing misfires

13/16 Inch Socket Models: 80% of Generac Units

Inverter Generators (2000-3500W)

Your iQ2000 or GP3500iO requires specialized attention. Small inverters under 3500W use 12.7 mm reach plugs (except the iQ3500/GP3500iO), while larger models need 19 mm reach. The iX2000 uniquely demands a 0.030″ gap—wider than other inverters. Always confirm reach by measuring your old plug: 12.7 mm units have shorter threaded sections visible below the hex head.

Critical replacement steps:

1. Remove the plug boot and clean debris from the cylinder head

2. Measure old plug’s reach with calipers (12.7 mm = 0.5″, 19 mm = 0.75″)

3. Set new plug gap to model-specific tolerance using a wire gauge

4. Hand-thread completely before final tightening

GP Open-Frame and RS-Series (3250-8000W)

From the GP3250 to XT8500EFI, these workhorses share 19 mm reach and 13/16″ hex heads. Note the GP3250’s outlier gap setting: 0.030″ versus the standard 0.028-0.031″ for other models. The RS5500/RS7000E and XT-series EFI units accept Champion N9YC or NGK BPR6ES plugs interchangeably. Pro tip: Apply anti-seize compound sparingly—aluminum heads seize plugs without it, but excess compound attracts carbon buildup.

5/8 Inch Socket Models: Commercial & Large Units

XC, XG, and XP Commercial Series

XC6500/XC8000E generators require 5/8″ sockets and Champion RC12YC plugs with a critically narrow 0.020″ gap. XG/XG7000E units use RC14YC plugs at 0.030″ gap—confusing these causes hard starting in commercial applications. Never substitute 13/16″ socket plugs; the smaller hex head shears under torque.

Massive GP15000E+ and Standby Units

Generac’s largest portable units (GP15000E/GP17500E) and standby models like the G0072289 demand 5/8″ sockets with 19 mm reach plugs. The 0.040″ gap on 15kW+ units is double most generators—too narrow causes carbon fouling during extended runtime. Industrial units use NGK BKR5E/BKR6E plugs; verify heat range matches your climate (BKR5E for hot environments).

Model-Specific Spark Plug Cheat Sheet

| Generator Series | Correct Socket Size | Critical Reach | Must-Have Gap | Top Replacement Plug |

|---|---|---|---|---|

| iQ/iX Inverters | 13/16″ | 12.7 mm (except iQ3500=19mm) | 0.023-0.030″ | NGK BPR6HS |

| GP3250 | 13/16″ | 19 mm | 0.030″ | Champion RN11YC |

| GP3600-GP8000E | 13/16″ | 19 mm | 0.028-0.031″ | NGK BPR6ES |

| XC Commercial | 5/8″ | 19 mm | 0.020″ | Champion RC12YC |

| XG/XP Commercial | 5/8″ | 19 mm | 0.030″ | Champion RC14YC |

| GP15000E+ | 5/8″ | 19 mm | 0.040″ | Champion RC14YC |

Installation Torque and Gap Protocol

Gap Settings That Make or Break Performance

Small inverters (2000-3500W): 0.023-0.030″—too wide causes misfires at high altitude. Standard generators (3250-8000W): 0.028-0.031″—critical for fuel-injected models like XT8000EFI. Commercial units: XC-series needs 0.020″ (use wire gauge, not blade type). 15kW+ units: 0.040″ gap prevents fouling during 24/7 operation. Never assume pre-gapped plugs are accurate—verify with a $5 wire gauge.

5-Step Installation Sequence

- Clean the cylinder head with compressed air—debris causes cross-threading

- Set gap using wire gauge (blade gauges compress electrode)

- Apply anti-seize to first 3 threads only—excess burns off and contaminates electrode

- Hand-tighten fully until resistance increases (prevents cross-threading)

- Torque to 15-20 ft-lb—use 18 ft-lb for aluminum heads, 15 ft-lb for cast iron

Warning: Overtightening cracks the ceramic insulator. Undertightening causes compression leaks—both kill spark.

Costly Mistakes That Destroy Generators

The 12.7 mm vs. 19 mm Reach Disaster

Installing a GP3500iO’s 19 mm plug (0J00620106) into an iQ2000’s 12.7 mm cylinder head pushes the electrode into the piston path. You’ll hear a metallic “clank” on startup followed by catastrophic engine failure. Always measure your old plug’s reach—it’s stamped on the side (e.g., “1/2” or “3/4″”).

Wrong Socket Size Consequences

A 13/16″ socket on an XC6500’s 5/8″ hex plug applies force unevenly, rounding the corners. Now you’re drilling out a seized spark plug—a $200+ repair. Verify socket size before touching tools: 13/16″ fits GP/iQ models, 5/8″ fits XC/XG/XP/GP15000E+.

Gap-Related Performance Failures

- 0.040″ gap on XC6500 (needs 0.020″): Weak spark fails to ignite fuel during cold starts

- 0.020″ gap on GP7500 (needs 0.030″): Carbon buildup fouls plug within 2 hours

- Uneven gap: Causes cylinder misfires—rotate plug 180° to check electrode wear

Maintenance Schedule That Prevents Failures

Annual inspection: Remove plug to check for:

– Electrode wear exceeding 0.040″ (replace immediately)

– Cracks in ceramic insulator (discard—no repair possible)

– Oil fouling (indicates piston ring failure)

Replacement intervals:

– 100 hours: Mandatory for portable generators (whichever comes first—annual or runtime)

– 200 hours: Required for commercial/continuous-duty units

– 2 years: Standby generators even with low runtime (fuel degrades plug)

Pro tip: Keep a pre-gapped plug in your emergency kit. For XC/XG series, pre-set gap to 0.020″ using a wire gauge—field adjustments fail under pressure.

Troubleshooting Guide for Spark Plug Issues

Generator Won’t Start? Verify These First:

- Socket size mismatch: Does your socket grip the plug fully?

- Reach verification: Compare new plug’s thread length to old one

- Gap accuracy: Measure with wire gauge—not assumed from box

- Torque check: Loose plug = compression leak; stripped threads = socket error

Performance Problems Decoded:

- Hard starting in cold weather: Gap too narrow (increase by 0.002″)

- Rough idle under load: Carbon buildup from incorrect heat range

- Power loss at high RPM: Too-wide gap extinguishes spark during combustion

Final Replacement Protocol

Always cross-reference your exact model number before purchasing. The GP3500iO and iQ3500 look identical but require different reach plugs—check your manual’s specification plate. For commercial units, upgrade to iridium plugs (NGK BKR6EIX) for 400+ hour service life—critical for job sites where downtime costs thousands per hour. Store spare plugs in anti-static bags; humidity degrades electrodes in 6 months.

Critical reminder: Generac’s 14 mm thread standard creates dangerous false confidence. A “universal” 14 mm plug fits physically but may destroy your engine. Match all four specifications—thread size, reach, hex size, and gap—or risk $500+ repairs. Keep this guide taped inside your generator’s maintenance kit; when the grid fails, you won’t have time to search online.