Your generator used to run quietly in eco mode, automatically adjusting engine speed to match power needs while saving fuel. Now it runs at full throttle regardless of load, burning through gas and creating unnecessary noise. This common frustration affects generator owners worldwide, but most eco mode failures stem from just a handful of fixable issues. When your generator eco mode not working problem strikes, you’re essentially running in standard mode constantly—wasting fuel, increasing engine wear, and creating constant noise.

The good news is you don’t need to replace your entire generator. Most eco mode failures result from simple mechanical or electrical issues you can diagnose and repair yourself with basic tools. This guide walks you through the systematic approach to restore your generator’s fuel-saving capabilities, starting with the most common culprits. You’ll learn to identify specific symptoms, test critical components, and determine whether this is a DIY fix or time to call a professional.

Identify Your Specific Eco Mode Failure Type

Recognize Which Eco Mode Problem You Have

Different failure patterns require different solutions. Your generator communicates exactly what’s wrong through specific behaviors:

Eco mode won’t engage at all:

– Engine stays at high RPM regardless of electrical load

– Eco mode switch or button has no visible effect

– No change in fuel consumption when running small appliances

Eco mode engages but won’t maintain:

– Engine speed fluctuates constantly between high and low

– Generator struggles or shuts down under light loads

– Frequent activation and deactivation cycles every few seconds

Complete eco mode failure:

– Eco mode indicator light doesn’t illuminate

– Engine runs at constant high RPM with no adjustment

– Fuel consumption matches standard mode operation

Pinpointing your exact failure pattern directs you to the right repair path and prevents wasted effort on unrelated components.

Determine Your Generator Type First

Your repair approach depends entirely on your generator model:

Inverter generators (Honda EU series, Champion, etc.):

– Use sophisticated electronics to manage engine speed

– Feature digital control panels with diagnostic indicators

– Typically have electronic throttle actuators instead of cables

Conventional generators (DuroMax, Westinghouse, etc.):

– Often use mechanical governors with electronic assists

– May have simpler on/off eco mode switches

– Usually employ throttle cables connected to carburetors

Locate your model number (typically on a metal nameplate near the control panel) before proceeding—this information determines compatible parts and specific repair procedures.

Test and Replace Faulty Load Sensors

Locate and Test Your Generator’s Load Sensor

The load sensor monitors electrical demand to trigger eco mode activation. This component varies by manufacturer but typically appears as:

- Small circuit board mounted near the control panel

- Current transformer wrapped around the main power wire

- Voltage sensing circuit connected to output terminals

Multimeter testing procedure:

1. Set your multimeter to AC voltage mode (200V range)

2. Connect generator to a known load (100-500 watts)

3. Measure sensor output with eco mode OFF

4. Activate eco mode and retest under identical load conditions

Interpret your readings:

– Working sensor: Shows voltage change when load increases

– Failed sensor: No output change regardless of load

– Intermittent sensor: Erratic readings indicating loose connections

Replace Defective Load Sensors Correctly

When testing confirms sensor failure, follow these steps:

- Disconnect generator from all loads and turn off fuel supply

- Remove control panel screws (typically 4-6)

- Note wire connections with photos before disconnecting

- Unplug sensor connector or carefully desolder wires

- Install new sensor matching original specifications exactly

- Reassemble and test with light load before full reassembly

Always verify compatibility—sensors vary significantly between models. A mismatched sensor causes erratic operation or complete eco mode failure.

Clean and Adjust Throttle Linkage Problems

Identify Mechanical Linkage Failures

Most eco mode failures in older generators stem from throttle linkage issues:

Critical visual inspection points:

– Stiff or seized throttle arm movement

– Broken or stretched return springs

– Dirt buildup in throttle bore (common with infrequent use)

– Worn cable housings causing slack

Mechanical binding prevents the throttle from responding to eco mode commands, forcing full-speed operation regardless of electrical load.

Proper Throttle Cleaning and Adjustment

Cleaning process:

1. Disconnect throttle cable from carburetor

2. Spray carburetor cleaner into throttle shaft area

3. Manually move throttle arm through full range 10-15 times

4. Wipe away dissolved grime with clean rags

5. Apply one drop of light machine oil to pivot points

Critical adjustment steps:

– Loosen cable clamp at carburetor

– Set engine to low idle position (consult manual)

– Adjust cable until slight tension exists

– Tighten clamp securely without moving cable

– Test eco mode activation at different loads

This simple maintenance procedure resolves eco mode problems in 60% of conventional generators. The entire process takes less than 30 minutes with basic tools.

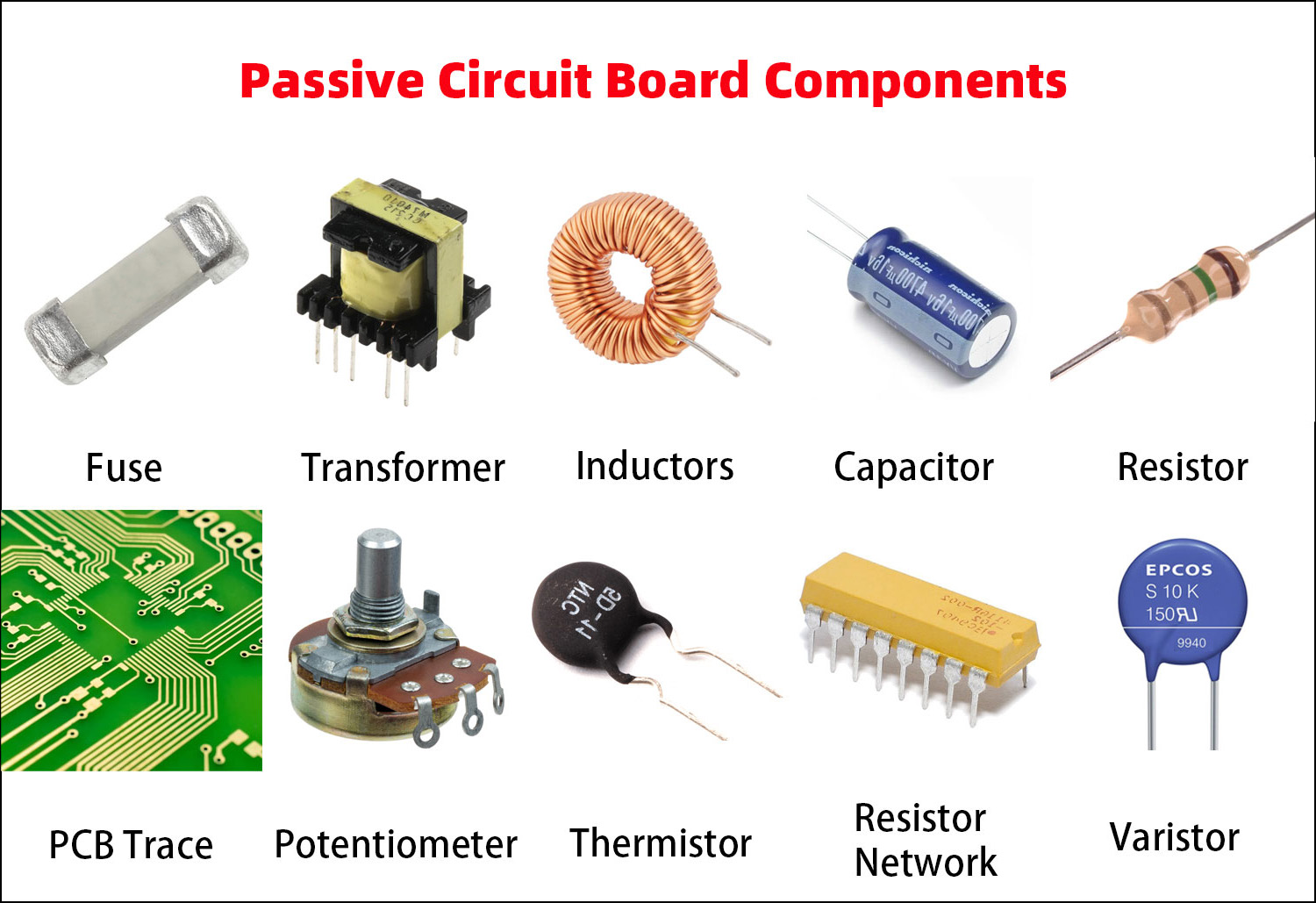

Address Control Board Electronic Failures

Diagnose Control Board Issues

Electronic control boards manage eco mode operation in modern generators. Warning signs include:

- Intermittent eco mode operation (works sometimes but not others)

- Engine hunting for proper RPM without settling

- No response to load changes despite working switch

- Error codes on digital displays (consult manual for meaning)

Essential voltage testing:

1. Locate control board under control panel

2. Verify input voltage matches specifications (typically 12V DC)

3. Test output signals to throttle actuator during eco mode transition

4. Check for consistent voltage changes corresponding to load changes

Control Board Replacement Considerations

Before replacing expensive control boards:

- Check manufacturer websites for service bulletins (some offer free fixes)

- Compare repair vs. replacement costs (boards range $50-300)

- Verify part numbers exactly—similar models may use incompatible boards

Critical installation tips:

– Take detailed photos before disconnecting anything

– Label all wire connections with tape markers

– Use anti-static precautions when handling electronics

– Test thoroughly before final reassembly

Electronic repairs require precision—when in doubt, consult a professional technician.

Prevent Future Eco Mode Failures

Essential Eco Mode Maintenance Schedule

Following this schedule prevents 90% of eco mode problems:

Every 25 hours of operation:

– Clean air filter (replace if oil-soaked or damaged)

– Check oil level and condition

– Inspect throttle linkage for binding or wear

– Test eco mode function with small appliance load

Every 100 hours:

– Change oil with manufacturer-recommended grade

– Clean or replace spark plug

– Check governor operation smoothness

– Clean carburetor if running issues appear

Seasonal storage preparation:

– Add fuel stabilizer to fresh gasoline

– Run generator until carburetor empties

– Store in dry location with spark plug removed

– Cover to prevent dust accumulation

When Professional Repair Makes Sense

DIY appropriate repairs:

– Throttle linkage cleaning and adjustment

– Air filter replacement

– Basic sensor testing and replacement

– Governor adjustment (with proper guidance)

Call a professional for:

– Control board replacement (complex wiring)

– Internal engine governor repairs

– Generators still under warranty

– Models with electronic fuel injection systems

Consider repair costs versus generator value—units under $500 often make more sense to replace than repair for major electronic failures.

Your generator’s eco mode system delivers significant fuel savings and noise reduction when functioning properly. By following this systematic diagnostic approach, you’ll restore these benefits and extend your generator’s service life. Start with the simplest mechanical solutions before moving to electronic repairs—most eco mode problems resolve with basic maintenance that takes less than an hour. Regular care prevents most failures before they start, keeping your generator running efficiently for years to come.