Your diesel generator’s radiator silently battles intense heat every time it powers up, but when coolant leaks appear or temperature gauges spike into the danger zone, immediate action is critical. Ignoring radiator issues leads to catastrophic engine failure within minutes, leaving you powerless during emergencies. This generator radiator repair guide delivers actionable steps to diagnose problems, execute temporary fixes, and determine when professional help is essential—ensuring your backup power remains reliable when storms hit or outages strike.

Why Your Generator Radiator Suddenly Fails During Peak Demand

Generator radiators prevent engine meltdown by cycling coolant through a precise thermal exchange process. As your diesel engine runs, coolant absorbs intense heat from combustion, then flows to the radiator where airflow dissipates that thermal energy before returning cooled fluid to restart the cycle. When this system breaks down, your generator has mere minutes before critical components warp or seize completely.

Without proper cooling, your generator faces four stages of failure: first, temperature warnings activate; next, power output drops as the engine throttles back; then automatic shutdowns occur to prevent damage; finally, permanent engine destruction happens if operation continues. A single overheating incident can cost thousands in repairs and leave you without backup power during critical outages—making prompt radiator attention non-negotiable for reliability.

Spot These 3 Critical Radiator Failure Signs Before Damage Occurs

Bright Coolant Puddles Under Your Generator Unit

Check beneath your generator weekly for telltale green or orange puddles—these indicate active coolant leaks requiring immediate attention. Even small drips compromise cooling efficiency and compound rapidly as air enters the system. Inspect hose connections for white crusty residue (dried coolant) and feel around seams for dampness. Never ignore minor leaks—they escalate quickly when thermal cycling stresses weakened radiator sections.

Temperature Gauge Spiking During Normal Operation

Watch for your generator’s temperature gauge climbing steadily into the red zone during standard load conditions. Consistent overheating—even if the unit hasn’t triggered automatic shutdown—signals restricted coolant flow or air blockage. Use an infrared thermometer to verify actual radiator surface temperatures; healthy units should show even cooling from top to bottom. Uneven heat distribution indicates internal blockages requiring professional cleaning.

Power Drops and Stalling During High Demand Periods

When your generator suddenly loses power output or stalls under load, suspect cooling system failure before electrical issues. Overheating forces the engine control module to reduce fuel delivery, causing noticeable performance degradation. Track fuel consumption—if it increases while power decreases, your radiator isn’t dissipating enough heat. These symptoms often precede complete shutdown, giving you a narrow window for intervention.

5-Minute Radiator Emergency Check Protocol

Weekly Coolant Level Verification Procedure

Check coolant levels every Monday during generator use by inspecting the reservoir fill line—never open the radiator cap when hot. Critical tip: Mark normal levels with tape to spot subtle drops between checks. A 10% level decrease indicates hidden leaks needing investigation. Always use manufacturer-specified coolant; mixing types creates gel-like sludge that blocks narrow radiator passages.

Radiator Fin Debris Removal Technique

Blockages from insects, leaves, or dust reduce cooling efficiency by up to 40%. Shut down your generator completely before cleaning. Use low-pressure compressed air (under 30 PSI) blown backward through fins—never a brush that bends delicate fins. For stubborn debris, apply a fin comb gently along the rows to straighten bent sections. Repeat quarterly in dusty environments or after major storms.

Pressure Testing for Hidden Leak Detection

Professional shops use pressure testers to find leaks invisible to the naked eye. Rent one ($25-$50) to pressurize your system to 15 PSI—the standard operating pressure for most generators. Watch for pressure drops over 10 minutes, then inspect heater connections, radiator seams, and the water pump weep hole. Warning: Never exceed manufacturer-specified pressure—this can blow out weak hoses.

Fix Small Leaks Before They Destroy Your Generator Engine

Temporary Sealant Application for Emergency Repairs

For minor leaks, radiator sealants like Bar’s Leaks offer 24-72 hours of operational insurance. Drain 2 quarts of coolant first to create space, then add the full bottle while running the generator at idle. Continue running for 15 minutes to circulate the compound. Critical limitation: Sealants only work on pinhole leaks under 1/16 inch—larger breaches require professional welding.

Proper Epoxy Repair for Plastic Tank Cracks

Clean affected areas with brake cleaner and a wire brush before applying two-part epoxy. Sand plastic tank surfaces with 80-grit paper for optimal adhesion. Apply epoxy with a plastic spreader, then clamp the area with C-clamps until fully cured (minimum 24 hours). Pro tip: Heat the epoxy with a hair dryer during application—it flows better into micro-cracks at 90°F.

When to Call Professionals Instead of DIYing

Seek immediate professional help if you see steam from the radiator, notice oil contamination in coolant (milky appearance), or experience repeated overheating after temporary fixes. These indicate internal engine damage where coolant mixes with oil—beyond DIY repair capabilities. Attempting major repairs yourself risks voiding warranties and causing catastrophic failure during your next power outage.

Chicago-Area Generator Radiator Repair Specialists

Rex Radiator’s Emergency Response for Critical Systems

With 115+ years in business, Rex Radiator handles everything from residential Generac units to industrial Caterpillar generators. Their mobile service vans reach most Chicago locations within 2 hours for emergency repairs. Key advantage: They fabricate custom radiators for obsolete models using OEM specifications—critical for facilities with older backup systems. Contact them at 630-595-4664 for 24/7 emergency service with a 1-year parts warranty.

Triangle Heavy Duty’s On-Site Industrial Solutions

For large commercial generators, Triangle Heavy Duty provides same-day on-location repairs when space permits. Their 50+ years of experience means they’ve seen every failure scenario imaginable. Unique capability: They modify cooling systems to accommodate discontinued parts—keeping aging generators operational without full replacement. Call 773-539-7676 for immediate support on industrial units powering hospitals or data centers.

Prevent Costly Breakdowns With This Maintenance Schedule

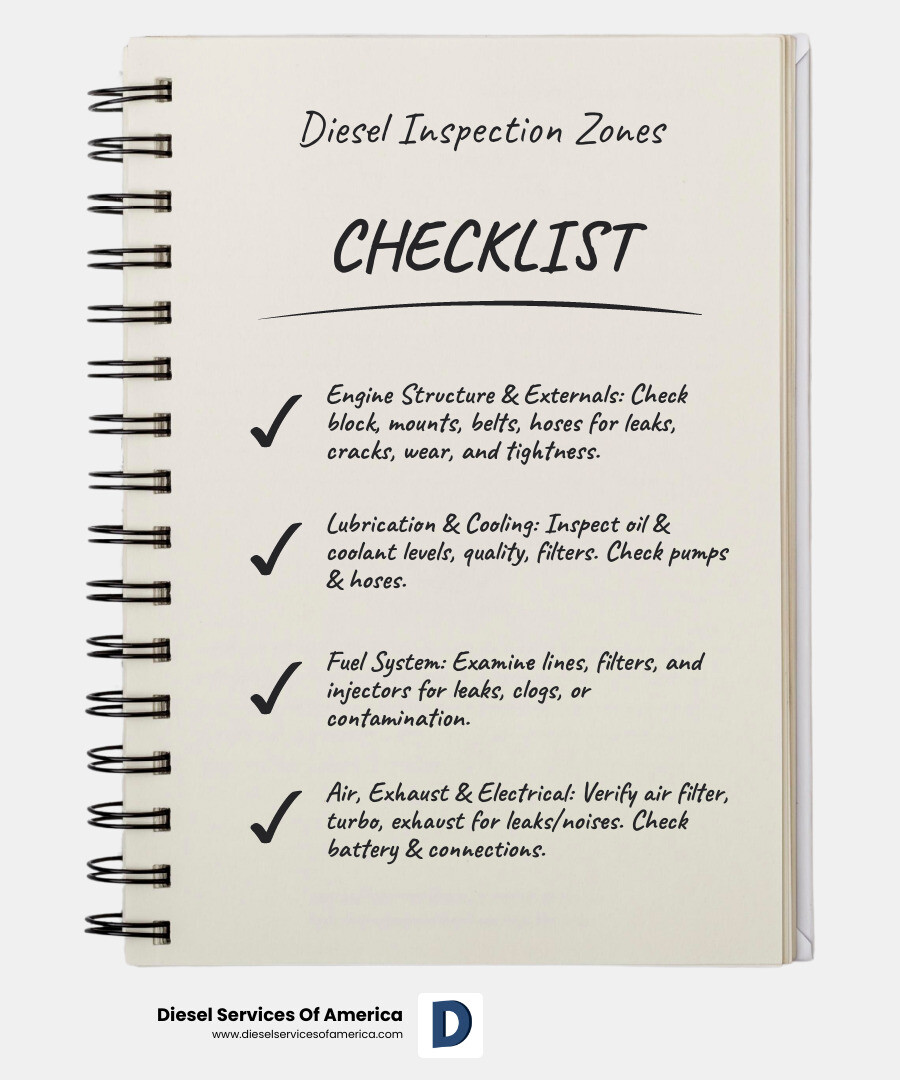

Monthly Generator Cooling System Checklist

- Verify coolant levels with generator cold and off

- Inspect all hoses for soft spots, cracks, or bulges

- Clean radiator fins using low-pressure air

- Check belt tension on water pump pulleys

- Document temperature readings during test runs

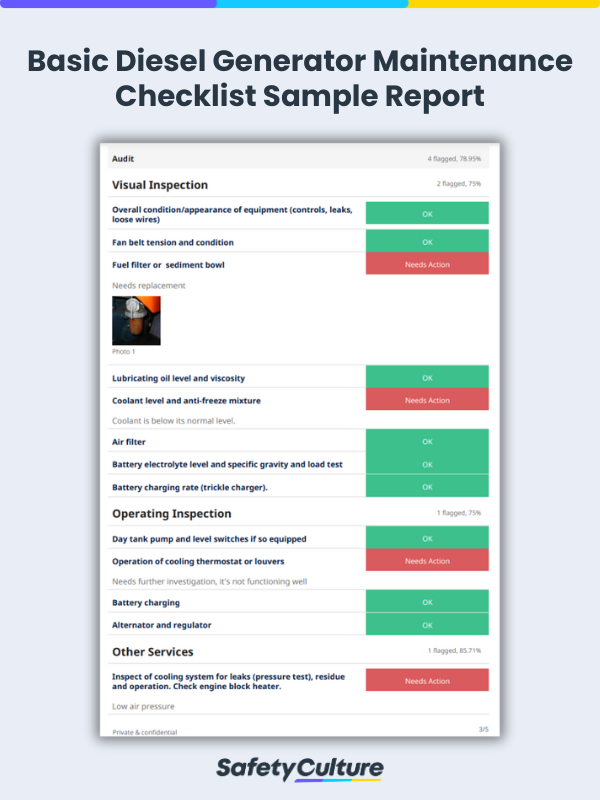

Quarterly Professional Service Must-Dos

- Pressure test entire cooling system

- Verify thermostat operation with infrared thermometer

- Replace coolant overflow reservoir if cracked

- Clean heat exchangers after 2,400 operating hours

- Test electric cooling fans for proper activation

Annual Overhaul for Maximum Reliability

Schedule complete coolant replacement every year—never exceed 600 operating hours between changes. Flush the system with专用 cleaner before refilling with fresh, manufacturer-approved coolant. Inspect water pump weep holes for seepage indicating seal failure. Replace all radiator hoses annually as preventive maintenance—they degrade internally even when externally sound.

Emergency Shutdown: What to Do When Smoke Appears

Immediate Power-Down Sequence to Save Your Engine

- Cut electrical load by disconnecting non-essential circuits

- Let generator idle for 2 minutes to cool components gradually

- Shut down completely using the emergency stop button

- Never open radiator cap while hot—wait minimum 2 hours

- Document symptoms (temperature readings, leak locations) for technicians

Temporary Fixes for Critical Power Needs

If you must restore power immediately, add a 50/50 mix of water and stop-leak compound to reach your nearest service center. Run the generator at minimal load (under 30% capacity) for no more than 30 minutes. Critical warning: Never operate with visible steam—this indicates boiling coolant and imminent engine seizure.

When Repair Costs Exceed Replacement Value

Radiator repairs become uneconomical when costs exceed 50% of a new unit’s price. For generators over 10 years old, replacement often makes more sense due to obsolete parts availability. Decision tip: If your radiator requires multiple welds or has extensive corrosion, replacement provides better long-term reliability. Modern aluminum radiators offer 25% better heat transfer than older copper-brass models—making upgrades worthwhile for critical facilities.

Your generator radiator demands proactive attention—not reactive panic when outages strike. Implement monthly inspections, schedule professional maintenance before failure occurs, and know your local emergency repair resources. A well-maintained cooling system prevents 92% of catastrophic generator failures, keeping your backup power ready when the grid goes down. Don’t wait for warning lights—your next power emergency demands a radiator that’s already in peak condition.