Your generator sits ready, but when the power goes out, silence. No comforting hum, no lights flickering back to life—just darkness. Transfer switch failures leave more than 35% of backup power systems useless when needed most. Whether you’re protecting your home’s essentials or keeping your RV’s systems running, a malfunctioning transfer switch can turn a minor outage into a major headache.

This guide walks you through systematic troubleshooting steps that separate simple fixes from professional service calls. You’ll learn to diagnose common failures, perform safe testing procedures, and know exactly when to call for backup. With these generator transfer switch troubleshooting techniques, you’ll maximize your backup power system’s reliability when the grid fails.

Generator Won’t Start During Power Outage

When your generator refuses to fire up during an outage, the transfer switch often hides the culprit. The two-wire communication system between your automatic transfer switch (ATS) and generator acts like a simple on/off switch—when it fails, your generator never receives the critical “start” signal.

Quick Generator Start Test Procedure

Start with this 30-second diagnostic that could save you hundreds in service calls. Locate the two small wires running from your transfer switch to the generator controller. Carefully disconnect these wires and touch their bare ends together. This manual short-circuit mimics a working transfer switch.

If the generator cranks and starts immediately, your transfer switch control board has failed. This small circuit board, usually field-replaceable, costs a fraction of a complete ATS replacement. Most manufacturers offer these as standalone components through their parts departments.

If the generator shows no response, the problem lies within the generator itself—low battery, fuel issues, or internal controller failure. Check your generator’s battery voltage (should be 12.6V or higher) and confirm fuel supply before proceeding with further troubleshooting.

Recognizing Control Board Failure Symptoms

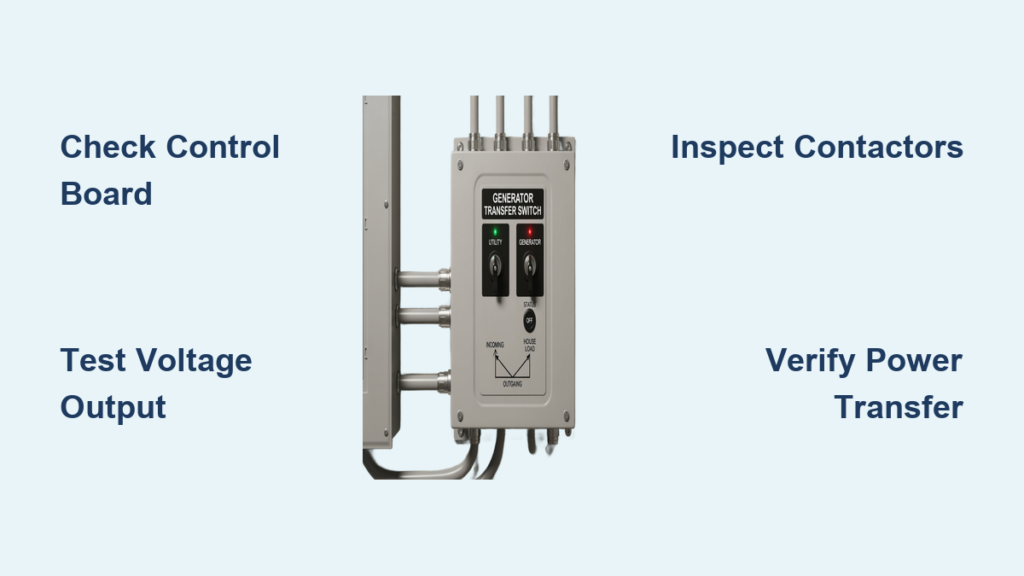

Failed control boards show clear warning signs beyond the generator start issue. Look for these specific indicators during your generator transfer switch troubleshooting:

- Burned plastic smell near the transfer switch enclosure

- Visible scorch marks on the control board or wiring harness connectors

- Relay chatter—rapid clicking sounds when utility power flickers

- Complete silence from the ATS during power outages (no relay activation sounds)

Generator Runs Continuously After Power Restoration

Your lights are back on, neighbors’ homes glow with utility power, but your generator refuses to shut down. This common failure wastes fuel, increases wear, and creates noise complaints. Proper generator transfer switch troubleshooting identifies why your system won’t recognize restored utility power.

Utility Power Recognition Verification Steps

Begin with a simple visual inspection of your ATS control panel. Most units display “UTILITY POWER” or similar indicators when normal power returns. No indicator light suggests the transfer switch isn’t recognizing the restored power.

Precision Voltage Testing Protocol

Grab your digital voltmeter and test the utility connection points with these exact specifications:

– Measure between each phase (black-to-red on 240V systems)

– Readings must stay within 5% of nominal voltage

– 240V systems should read 228-252V

– 208V systems need 198-218V

Voltage within range but no recognition equals control board failure. Lightning strikes commonly cause these transient surges that damage voltage sensing circuits. Your generator transfer switch troubleshooting should focus on the control board in this scenario.

Generator Stop Diagnostic Test

Disconnect the two communication wires from the ATS while the generator runs. If the generator stops immediately, confirm ATS control board failure. If the generator continues running, the problem lies within the generator’s own control system rather than the transfer switch.

ATS Won’t Transfer to Generator Power Despite Running Unit

The generator runs perfectly, voltage looks good, but your house remains dark. This failure pattern typically involves power quality issues or damaged contactors. Effective generator transfer switch troubleshooting requires precise measurements.

Generator Power Recognition Confirmation

Check your ATS display for “GENERATOR POWER” or emergency power indicators. Absence of these indicators suggests the switch doesn’t recognize your generator’s output as acceptable power. Many homeowners mistakenly assume generator problems when the transfer switch is actually rejecting the power.

Critical Voltage and Frequency Testing Procedures

Voltage testing at emergency lugs requires precision:

– Test phase-to-phase voltage (black-to-red)

– Must read within 5% of nominal system voltage

– 240V systems: 228-252V acceptable range

Frequency verification trumps generator display readings:

– Use digital voltmeter’s frequency setting (not generator display)

– Must maintain ±3.0 Hz tolerance

– 60 Hz systems need 57-63 Hz for ATS acceptance

– 50 Hz systems require 47-53 Hz

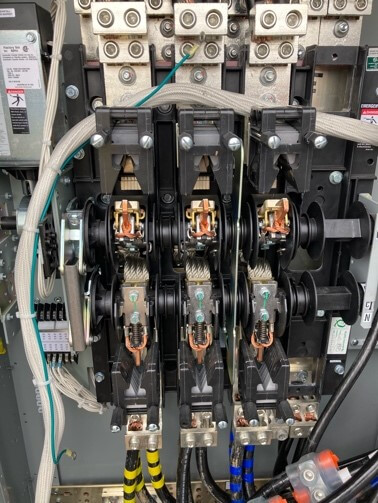

Contactor Damage Inspection Checklist

Open your ATS panel and examine the large magnetic contactors. Look for these specific signs of damage:

– Burned or pitted contact surfaces visible through inspection windows

– Melted plastic housing around contactor assemblies

– Discolored or swollen relays indicating thermal damage

– Loose wire connections at contactor terminals causing arcing

RV Transfer Switch Half-Power Failures

RV owners face unique challenges with 50-amp systems powering multiple circuits. When half your outlets die, the transfer switch often harbors the problem. Generator transfer switch troubleshooting for RVs requires specialized approaches.

Partial Power Failure Root Cause Analysis

Failed single contact in 50-amp ATS systems creates this symptom. Your RV uses two hot legs (red and black wires) feeding separate circuits. One burned contact kills power to half your electrical system while the other functions normally. This is the most common cause of “half the RV works” scenarios during generator operation.

Terminal Connection Safety Warning

Never randomly tighten terminal screws on RV transfer switches. Over-tightening snaps terminals off expensive contactors, turning a simple fix into complete ATS replacement. Use proper tools and techniques only—this is critical for safe generator transfer switch troubleshooting in RV applications.

Five-Step RV Transfer Switch Diagnostic Protocol

TEST 1 – Shore Power Verification

– Meter setting: 600V AC

– Test points: red-white, black-white, black-red

– Expected: 120V white-to-red and white-to-black, 240V black-to-red

– Failure here indicates pedestal, adapter, or cordset issues

TEST 2 – Generator Power Validation

– Start generator, wait for stabilization

– Test generator incoming connections

– Expect 120V red-white and black-white, 0-240V black-red

– Low readings point to generator circuit breakers or internal problems

TEST 5 – Generator Power Transfer Confirmation

– Generator running, relay clicked

– Test outgoing voltage to RV load center

– Must match TEST 2 readings

– Mismatched readings require ATS replacement due to burned generator contacts

Essential Safety Protocols for Transfer Switch Testing

Working with transfer switches means handling lethal voltages. These systems operate at levels that can kill instantly. Generator transfer switch troubleshooting must prioritize safety above all else.

Live Testing Safety Requirements

Only qualified technicians should perform live electrical testing. If you lack formal electrical training, stop at visual inspections and call a professional. The diagnostic steps outlined require proper tools, knowledge, and safety equipment. Never bypass safety interlocks or work on energized equipment without appropriate personal protective equipment.

Emergency Service Indicators

Call immediately when you observe:

– Visible burning or melting components

– Strong electrical odors (ozone or burning insulation)

– Sparks or arcing sounds during operation

– Repeated breaker trips after reset attempts

– Any hesitation about safety procedures

When to Replace vs Repair Your Transfer Switch

Control board failures offer cost-effective solutions. These small circuit boards cost $50-200 versus $400-800 for complete ATS replacement. Most manufacturers design these as field-replaceable units.

Contact or contactor damage usually requires complete ATS replacement. Individual components rarely match exactly, and field repairs create safety hazards that compromise your backup power system.

Visible burning or melting demands immediate professional assessment. These symptoms indicate cascading failures that simple part swaps won’t resolve and may have damaged connected equipment.

Monthly Maintenance Prevents Most Transfer Switch Failures

Simulate power outages by turning off your main breaker monthly, ensuring the entire sequence functions correctly. This 5-minute test identifies problems before emergencies strike.

Keep terminal connections tight using proper torque specifications (25-50 inch-pounds). Annual inspection by qualified technicians catches developing issues early. Clean contact surfaces and verify all mechanical interlocks operate smoothly.

Your transfer switch stands between darkness and comfort during outages. Understanding these generator transfer switch troubleshooting procedures helps you distinguish simple fixes from situations demanding professional intervention. When power fails, you’ll know exactly what to check—and when to make the call that keeps your backup system ready for the next outage.