Your generator sputters to life but delivers no power, or worse—it dies completely during a critical outage. The repair shop diagnosed “winding issues,” leaving you staring at a potential replacement cost that could bankrupt your operation. Generator winding repair isn’t just a fix—it’s a strategic decision that can save you 30-50% compared to replacement costs for industrial equipment. Whether you’re dealing with a portable home unit or a 50,000 HP industrial generator, this guide reveals exactly what happens during professional winding repair, how to recognize problems early, and when DIY solutions might work.

Why Your Generator Windings Fail (And How to Spot It First)

Burning Smells and Voltage Fluctuations: Early Warning Signs

When your generator emits a distinct burning odor during operation, you’re witnessing insulation breakdown in real time. This chemical smell indicates the varnish coating on windings is deteriorating, a critical failure point that often precedes total breakdown. Voltage fluctuations under load—where your generator works fine at idle but sags dramatically when powering equipment—signal partial winding shorts that compromise performance. Excessive vibration during operation points to mechanical damage within the windings, while unusual grinding or clicking noises often precede complete electrical failure.

Visual Inspection Checklist Before Calling a Professional

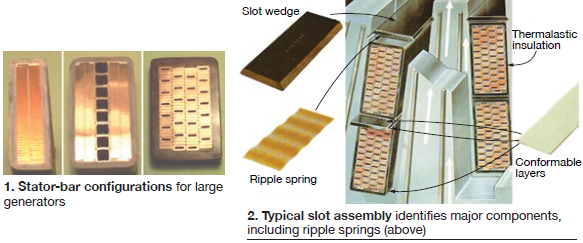

Conduct this 5-minute visual assessment before professional testing: Locate discolored windings that appear darker than surrounding areas, particularly near connection points. Check for burnt insulation showing as brittle, flaking material or melted varnish pooling at the base of coils. Inspect connections for frayed or separated leads that indicate thermal stress damage. Examine slot wedges for physical damage—broken wedges allow windings to shift and short against the core. Finally, look for corrosion around terminals, which signals moisture infiltration compromising electrical integrity. Warning: Never attempt internal inspection while the generator is running or connected to power.

How to Identify Generator Winding Failures Before Catastrophe

Professional Electrical Testing You Should Demand

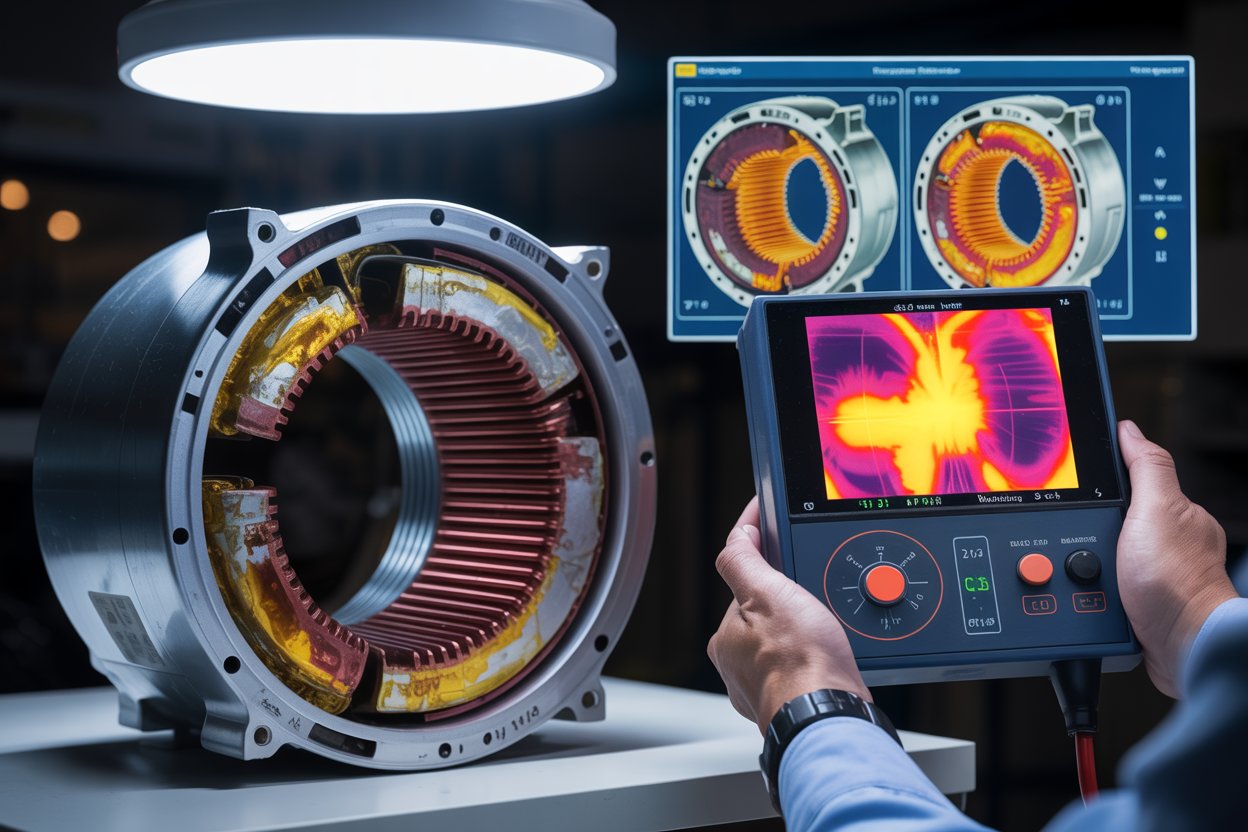

When your generator shows symptoms, insist on these specific tests from any repair facility: Phase comparison tests identify winding imbalances causing uneven power distribution—a common issue in three-phase generators. Hi-potential tests apply controlled overvoltage to detect insulation weaknesses before catastrophic failure occurs. Dielectric absorption tests measure insulation quality against moisture and contamination, critical for generators operating in humid environments. Motor Current Evaluation (MCE) provides comprehensive electrical analysis, while thermographic surveys reveal hot spots invisible to the naked eye. Pro tip: Reputable shops provide test reports showing before-and-after measurements.

Advanced Diagnostic Tools That Prevent Repeat Failures

Modern repair facilities use sophisticated equipment that goes beyond basic testing: Computer-assisted predictive maintenance systems analyze vibration patterns to predict winding failures months in advance, allowing planned maintenance. Laser alignment systems ensure mechanical components meet exact specifications—misalignment stresses windings and causes premature failure. Ultrasonic testing equipment detects internal winding faults without disassembly, saving diagnostic time. Precision balancing apparatus identifies mechanical issues contributing to electrical failures. Key insight: These tools verify whether your problem stems from winding damage alone or underlying mechanical issues causing the winding failure.

Complete Generator Rewinding: What Actually Happens in the Shop

Step-by-Step Breakdown of the Rewinding Process

Professional rewinding begins with systematic disassembly—each component (stator, armature, AC rotor, exciter stator, and PMG stator) undergoes meticulous examination. Technicians document insulation breakdown locations, physical winding damage, and mechanical faults to determine if partial repair or complete rewinding offers the most cost-effective solution. Old windings are carefully extracted using specialized removal tools that prevent core damage—a single damaged core slot can compromise the entire repair. Following removal, cores undergo thorough cleaning to eliminate residual insulation and contaminants, with core testing verifying structural integrity before rewinding begins.

Precision Specifications That Make or Break Your Repair

New windings must match exact original specifications: Wire gauge and type follow manufacturer requirements to handle electrical loads without overheating. Turn count calculations ensure proper voltage and frequency output—just 2% deviation can cause performance issues. Winding patterns configure for specific electrical characteristics, while lead connections critically influence generator performance. Custom coil manufacturing accommodates equipment up to 25,000 HP, ensuring perfect fit and function. Critical mistake to avoid: Using generic wire specifications that don’t match original thermal and electrical requirements—this causes premature failure.

Advanced Insulation Systems That Prevent Future Winding Failures

Modern Insulation Technologies for Maximum Protection

Contemporary generators demand advanced insulation systems that withstand today’s electrical challenges: Inverter voltage spike resistant insulation protects against modern electronic loads that create damaging voltage spikes. Thermalastic coil insulation withstands high operating temperatures without degradation, extending winding life. Epoxy Vacuum Pressure Impregnation (VPI) provides superior environmental protection by filling microscopic voids that cause insulation breakdown. Dip and bake processes offer reliable traditional insulation solutions for standard applications. Expert note: Insulation selection depends on your specific operating environment—don’t accept a one-size-fits-all solution.

Matching Insulation to Your Operating Environment

Select insulation based on your generator’s actual working conditions: Moisture-resistant systems suit humid environments like coastal installations or indoor facilities with high humidity. Chemical-resistant coatings protect against industrial contaminants in manufacturing settings. Vibration-resistant insulation prevents mechanical stress damage in mobile applications or facilities with high ambient vibration. Temperature-rated systems must match your generator’s specific thermal requirements—using insulation rated for 130°C on equipment running at 155°C causes rapid failure. Pro tip: Ask your repair facility to document the insulation class (A, B, F, or H) they’re installing—this directly impacts warranty coverage.

Critical Post-Rewind Tests That Guarantee Generator Reliability

Essential Verification Tests Before Accepting Your Repair

Never accept a rewound generator without these verification tests: Electrical parameter testing must confirm voltage, current, and power output meet specifications under varying loads. Physical inspection verifies proper installation and connection integrity—loose connections cause immediate failure. Performance testing under actual load conditions ensures reliable operation before you take delivery. For aviation applications, certified technician oversight with aviation performance standards compliance is non-negotiable. Warning: Facilities that skip load testing are taking shortcuts that risk premature failure.

Documentation That Protects Your Investment

Professional repairs include comprehensive documentation: Test certificates must verify electrical parameters meet specifications with before-and-after measurements. Warranty documentation should specify 12 months in-service or 18 months from shipment coverage. Performance records provide baseline data for future maintenance comparisons. Component tracking ensures traceability for critical applications like aviation generators. Key question: Ask “Can you provide written test results showing the generator passed IEEE and NEMA standards?”—reputable facilities will have these documents ready.

Portable Generator Re-Excitation: DIY Fixes That Actually Work

Why Your Portable Generator Loses Power (Even With a Running Engine)

Portable generators lose residual magnetism when stored without operation—typically after 6-12 months of inactivity. This demagnetization prevents electricity production despite proper engine function because the field coils require an initial magnetic field to generate power. Unlike permanent magnet generators, most portable units rely on this residual magnetism to start the electricity generation process. Critical insight: This isn’t a winding failure but a related issue that mimics winding problems—fix it before assuming you need professional rewinding.

Three Proven Re-Excitation Methods (With Exact Steps)

6-Volt Battery Method: The Coleman-Approved Technique

- Locate the brush assembly (typically behind a 1″ x 4″ inspection plate)

- Identify positive and negative brush connections (consult your manual)

- Start the generator engine and let it reach operating speed

- Momentarily connect 6-volt battery positive to generator brush positive

- Simultaneously connect battery negative to generator brush negative

- Limit connection to 1-2 seconds maximum—longer can damage components

- Test power output immediately after disconnecting

Light Bulb Method for Visual Confirmation

Connect three 75-watt bulbs in series between a 120V AC source and generator output. A brief flash indicates successful re-excitation—the series connection limits current while providing visual confirmation. This method works best for generators with standard 120V output.

Electric Drill Method for Immediate Results

Connect a corded electric drill to the generator output. Start the generator engine, then manually spin the drill chuck in reverse direction while the trigger is depressed. This induces sufficient magnetic field restoration through motor-generator action—often working in under 30 seconds.

When Repair Beats Replacement: Generator Winding Cost Analysis

The Real Economics of Generator Winding Repair

Professional winding repair typically costs 30-50% of replacement for industrial generators over 500 HP. For custom-built equipment, repair avoids months of manufacturing lead time—critical for operations where downtime costs exceed $10,000 per hour. Emergency field services reduce transportation costs and downtime by performing repairs on-site. Critical calculation: Factor in total cost of ownership including downtime, transportation, installation, and lost production—not just the repair quote.

Warranty Protections That Make Repair Risk-Free

Reputable facilities offer comprehensive guarantees that eliminate repair risk: 100% OnTime delivery ensures schedule compliance with penalty clauses for delays. 100% OnSpec performance guarantees operational requirements are met before payment. 100% OnBudget service prevents cost overruns with fixed-price contracts. The standard 12-month in-service warranty provides protection against premature failure. Expert advice: Always get warranty terms in writing before authorizing repair—verbal promises mean nothing when problems arise.

10 Must-Ask Questions Before Hiring a Generator Winding Repair Service

Before entrusting your critical equipment to a repair facility, demand answers to these essential questions: Do you have crane capacity for my generator size? (Critical for units over 10 tons) Are your technicians certified for my specific generator type? (Aviation requires different expertise than industrial) What insulation systems do you use for my operating environment? Can you perform on-site repairs to minimize downtime? What testing standards do you follow? (IEEE, NEMA, aviation-specific) Do you provide written test reports? What’s your emergency response time? How do you handle obsolete or custom equipment? What’s included in your warranty? Can you provide references from similar projects? Red flag: Any facility that can’t answer these questions thoroughly isn’t worth your business.

Generator winding repair transforms what seems like a catastrophic failure into a manageable maintenance event. By understanding the repair process, recognizing early warning signs, and knowing what to demand from service providers, you protect your critical power infrastructure. Remember: The most expensive generator repair is the one you didn’t do—acting quickly when symptoms appear prevents minor issues from becoming total failures. Implement monthly visual inspections and quarterly electrical testing to catch problems early, and always choose certified facilities with documented capabilities matching your specific generator type. Your generator, whether powering a remote worksite or a hospital emergency system, can deliver reliable service for decades with proper winding care.