You’re sitting in your living room with lights blazing, phone charging, and air conditioning humming—yet most people never stop to wonder how spinning motion becomes the electricity powering their entire life. Behind every wall outlet lies a remarkable dance of physics where fluid flow transforms into electromagnetic force, creating the invisible energy that runs our modern world. Understanding how a turbine generator works reveals the elegant engineering that converts everything from rushing water to burning gas into reliable electrical power.

This process isn’t just academic—it’s the backbone of civilization. From massive hydroelectric dams to compact backup generators, the same fundamental principles apply. By grasping these mechanics, you’ll understand why some power plants respond instantly to demand spikes while others require hours to ramp up, why hydrogen cooling matters more than you think, and how renewable sources integrate into existing grids.

The Electromagnetic Conversion Process That Powers Your Home

Every turbine generator operates on a brilliantly simple principle: moving magnets create electricity. When magnetic fields rotate past copper conductors, they push electrons into motion—literally generating electrical flow from mechanical spin. This electromagnetic induction, discovered nearly two centuries ago, remains the foundation of all modern power generation.

The conversion follows a precise mathematical relationship: E = BLV determines voltage output based on magnetic flux density, conductor length, and rotational velocity. Faster rotation equals higher voltage, which explains why maintaining consistent turbine speed is crucial for stable electrical output. The beauty lies in this direct relationship—mechanical energy input directly controls electrical energy output.

Why Generator Rotation Speed Must Be Precisely Controlled

Power grids operate at specific frequencies—60 Hz in North America, 50 Hz in most other regions. Your turbine generator must maintain exact rotational speed to match these frequencies. For a 60 Hz system, a two-pole generator spins at exactly 3,600 RPM. Even slight deviations cause frequency fluctuations that can damage connected equipment.

Pro Tip: Grid operators constantly monitor generator speed and automatically adjust turbine input to maintain perfect synchronization with the grid frequency—this balancing act happens continuously, 24/7.

Critical Components That Make Your Turbine Generator Function

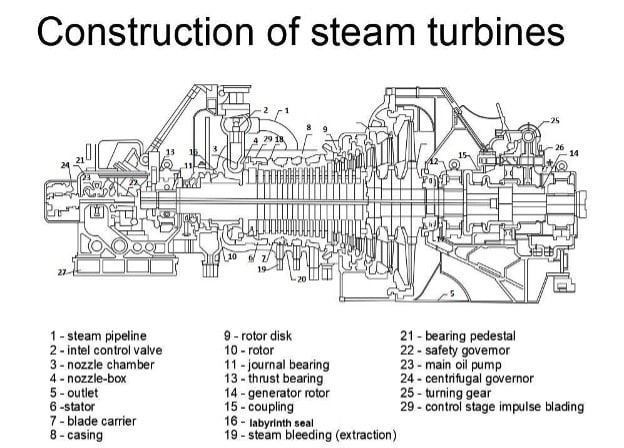

All turbine generators share four essential elements working in perfect harmony. The turbine captures energy from moving fluid—whether steam, gas, or water—and transforms it into rotational mechanical energy. This rotation transfers through a shaft to the generator, where the actual energy conversion occurs.

Inside the generator, a rotor spins electromagnets past stationary stator windings. The stator contains hundreds of copper coils precisely arranged to maximize electromagnetic interaction. As rotor magnets sweep past these coils, they induce electrical current without any physical contact between moving parts.

How Different Energy Sources Drive the Same Generator Principle

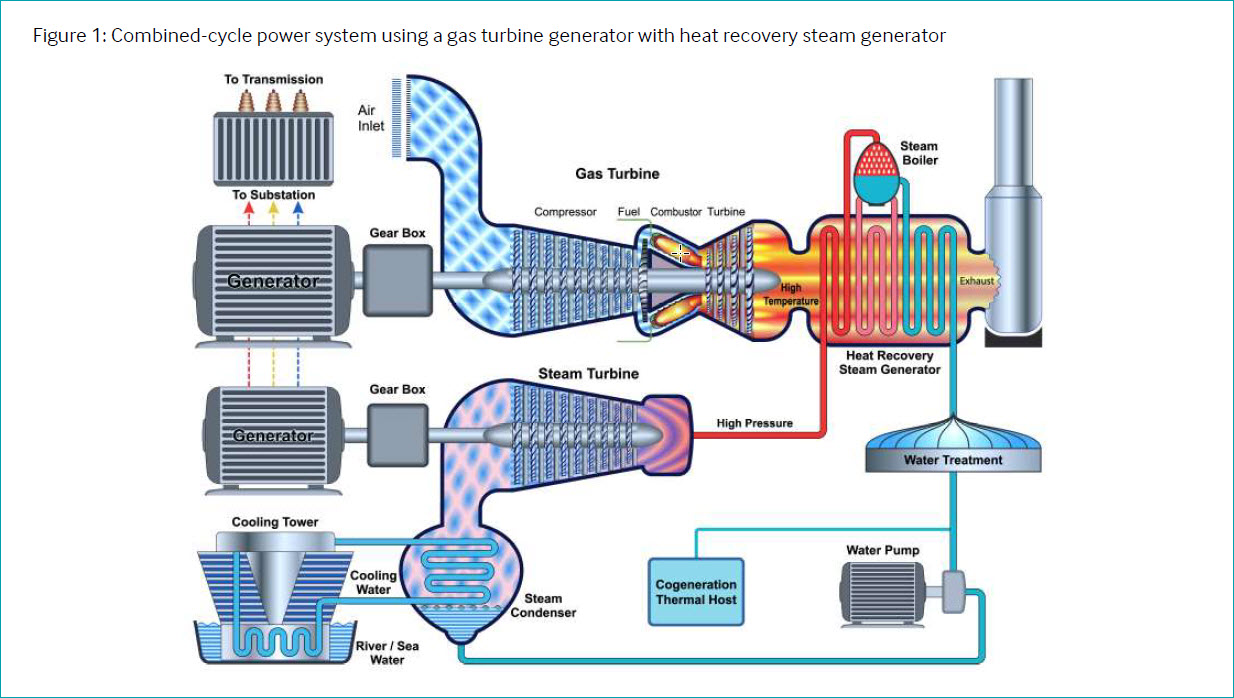

Gas turbine systems compress incoming air to high pressure before mixing it with fuel in a combustion chamber. The resulting explosive expansion drives turbine blades, which connect directly to the generator rotor. These systems operate like jet engines, capable of reaching full power within minutes to meet sudden demand increases.

Steam turbine systems use external heat sources—coal, nuclear, or concentrated solar—to create pressurized steam. This steam flows through carefully designed blade paths, gradually expanding and losing pressure while transferring energy to the turbine shaft. The continuous water-steam cycle enables sustained power generation with remarkable efficiency.

Hydroelectric systems harness flowing water’s kinetic energy through specialized hydraulic turbines. These systems maintain fixed rotational speeds determined by grid frequency requirements, creating predictable, consistent power output. The magnetic field poles on the rotor perimeter sweep past stator conductors at precise intervals, generating clean electricity from renewable water flow.

The Hidden Physics Behind Your Electricity Bill

Large generators create powerful electromagnets by circulating direct current through wire loops wrapped around magnetic steel laminations. These field poles mount on the rotor’s perimeter, creating intense magnetic fields that rotate past stationary stator conductors. As the rotor turns, these moving magnetic fields induce electrical current in the stator windings—no physical contact required.

The process generates enormous torque—the rotational force that transmits mechanical energy from turbine to generator. Operators meticulously regulate turbine speed to maintain consistent power output, adjusting for electrical grid demands in real-time. This synchronization ensures the generator produces electricity at exactly the correct frequency and voltage for grid integration.

What Happens When You Flip a Light Switch

When you activate an electrical device, you’re creating demand on the grid. Here’s what happens behind the scenes:

- Your device draws current, increasing electrical load

- This creates resistance against the generator’s rotation

- Turbine control systems detect the slight speed decrease

- More fuel or steam is introduced to the turbine

- Increased mechanical input maintains constant rotational speed

- Additional electricity is generated to meet your demand

This entire process happens in milliseconds, demonstrating how your turbine generator works as a responsive, dynamic system rather than a simple on/off device.

Why Generator Cooling Systems Are More Critical Than You Think

Heat represents the primary enemy of generator efficiency. Moving electrons through conductors inevitably creates thermal energy, which degrades electrical insulation over time. Excessive temperatures reduce the insulation’s ability to contain voltage, potentially causing catastrophic failures.

Hydrogen cooling offers superior performance—hydrogen conducts heat 14 times better than air while operating as pressurized gas at 30 psi. This enables smaller, more efficient generators to produce higher outputs while reducing operational costs. The hydrogen is contained within the generator housing, circulating to absorb heat before passing through coolers.

Common Cooling System Failures to Watch For

- Hydrogen leaks: Even small leaks reduce cooling efficiency significantly

- Oil contamination: Can degrade hydrogen purity and cooling performance

- Cooler blockages: Reduce heat transfer capability

- Temperature imbalances: Uneven cooling creates stress points in windings

Expert Note: Regular monitoring of hydrogen purity (typically maintained above 98%) and temperature differentials across the generator are essential for preventing unexpected shutdowns.

Maintenance Strategies That Extend Generator Lifespan

Generators fail through predictable patterns: mechanical component wear, synchronization errors, excitation loss, and unbalanced armatures. Understanding how a turbine generator works helps technicians anticipate these failures before they occur.

Stator rewinds restore electrical insulation to peak performance, while rotor rewinds bring electrical systems back to original specifications. These upgrades integrate newer technologies into existing units, extending service life significantly. Modern insulation materials can withstand higher temperatures, allowing generators to produce more power without physical modifications.

The 5-Point Generator Health Check

Perform these checks during routine maintenance to catch problems early:

- Insulation resistance testing: Measures degradation in winding insulation

- Vibration analysis: Identifies mechanical imbalances before they cause damage

- Partial discharge monitoring: Detects early-stage electrical insulation breakdown

- Hydrogen purity verification: Ensures optimal cooling performance

- Brush and slip ring inspection: Critical for excitation systems in larger generators

Time-Saving Tip: Implement continuous monitoring systems that track these parameters in real-time, allowing predictive maintenance rather than reactive repairs.

How Your Turbine Generator Integrates With the Power Grid

Modern generators seamlessly blend traditional and renewable energy sources. Wind turbines use the same electromagnetic principles as hydroelectric systems, while concentrated solar power creates steam for conventional turbines. Natural gas plants provide flexible backup for intermittent renewable sources, creating hybrid systems that maximize both efficiency and reliability.

Combustion turbines excel at rapid startup, operating like jet engines to meet sudden power demand spikes. These systems can reach full capacity within minutes, providing essential grid stability during high-demand periods. Their flexibility makes them invaluable for maintaining reliable electrical supply.

Steam turbines dominate continuous power generation, providing the steady baseline electricity that grids require 24/7. Combined-cycle systems optimize both efficiency and reliability by integrating gas and steam turbines in single configurations. Hydroelectric systems contribute renewable base load power through consistent water flow utilization.

The Future Evolution of Turbine Generator Technology

The evolution continues as generators adapt to changing energy landscapes. Hydrogen-ready turbines, improved cooling systems, and advanced materials push efficiency boundaries while reducing environmental impact. Understanding how a turbine generator works reveals the remarkable engineering that transforms fluid motion into the electrical energy powering every aspect of modern life.

New generator designs incorporate digital twins—virtual models that simulate performance under various conditions. These allow operators to optimize performance, predict failures, and test modifications before implementing them on physical equipment. The same fundamental principles discovered by Faraday still apply, but modern implementations continue to improve efficiency and reliability.

When you next pay your electricity bill, remember the intricate physics and engineering working behind the scenes. From the water rushing through hydroelectric dams to the natural gas spinning combustion turbines, the process of how a turbine generator works remains one of humanity’s most elegant solutions to our energy needs—a perfect marriage of mechanical motion and electromagnetic force delivering power to your doorstep.