Picture arriving at a remote construction site and plugging your equipment into a silent box that delivers clean electricity with zero emissions. No diesel fumes, no engine noise—just pure power from hydrogen. This isn’t science fiction; hydrogen generators are already replacing traditional generators worldwide. But how does a hydrogen generator work to create this clean energy? The answer lies in two complementary technologies: electrolyzers that make hydrogen from water, and fuel cells that turn hydrogen back into electricity. Both leverage the same fundamental chemistry but operate in reverse directions. Understanding these processes reveals why hydrogen is rapidly becoming the backbone of clean energy systems for construction sites, data centers, and remote communities.

Electrolysis Creates Green Hydrogen from Water

Water Splitting Chemistry Explained

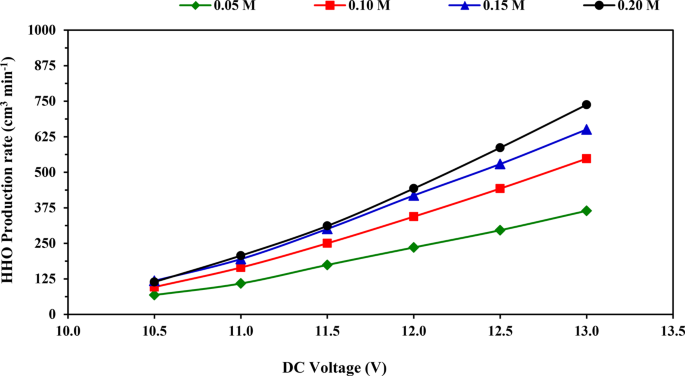

At its core, an electrolyzer-type hydrogen generator uses electricity to split water molecules. When direct current flows through water containing an electrolyte, chemical reactions occur at two electrodes. At the anode, water molecules lose electrons to produce oxygen gas (2 H₂O → O₂ + 4 H⁺ + 4 e⁻). Simultaneously at the cathode, protons gain electrons to form hydrogen gas (4 H⁺ + 4 e⁻ → 2 H₂). The result? Pure hydrogen and oxygen emerge from separate outlets with no harmful byproducts. This molecular transformation requires precise control—too much current causes overheating, while impurities in the water can damage critical components. You’ll notice visible gas bubbles forming almost immediately when the system activates, with hydrogen production rates directly tied to electrical input.

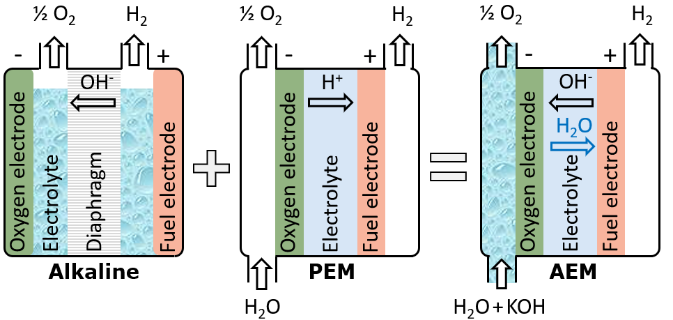

Three Main Electrolyzer Types Compared

Alkaline electrolyzers use liquid potassium hydroxide as the electrolyte and have powered industrial applications since the 1950s. While robust and cost-effective for large-scale operations (1–100 MW+), their slower response to power fluctuations makes them less ideal for pairing with variable solar or wind sources. PEM (Proton-Exchange-Membrane) electrolyzers employ solid polymer membranes that enable rapid response within seconds. These compact units achieve higher current densities but require expensive platinum-group catalysts, increasing upfront costs. Solid oxide electrolyzers operate at extreme temperatures (700–1000°C), leveraging waste heat to reach 80–90% efficiency—the highest of any system. However, thermal stress during startup/shutdown cycles creates durability challenges, limiting current deployment to research and specialized applications.

Essential Components Beyond the Electrolysis Stack

A complete hydrogen generator includes critical subsystems working in concert. Power electronics convert grid or renewable AC power to the precise DC voltage required for electrolysis. Water purification systems remove contaminants that could degrade membranes, especially crucial for PEM units. Gas processing equipment dries and purifies hydrogen to 99.999% purity through knock-out drums and de-oxidizers. Safety systems continuously monitor for leaks using hydrogen detectors and automatically trigger inert gas purging if concentrations exceed safe levels. These ancillary components add complexity but ensure reliable operation—without them, even minor impurities could clog membranes or create explosive mixtures.

Fuel Cells Generate Electricity from Stored Hydrogen

Reverse Chemistry Powers Your Equipment

When operating as a fuel-cell generator, the process reverses: hydrogen becomes the fuel. Compressed hydrogen enters the anode side where a catalyst splits it into protons and electrons (H₂ → 2 H⁺ + 2 e⁻). The protons pass through a membrane while electrons travel an external circuit—creating usable electricity. At the cathode, oxygen from air combines with returning electrons and protons to form pure water (½ O₂ + 2 H⁺ + 2 e⁻ → H₂O). This continuous flow sustains electrical generation as long as hydrogen and oxygen are supplied. Unlike combustion generators, there’s no flame or moving parts in the power generation stage—just silent electrochemical reactions producing only water vapor as exhaust.

Real-World System Architecture for Reliable Power

Modern hydrogen power units integrate everything needed for grid-quality electricity. Fuel cell stacks contain hundreds of individual cells connected in series, with each cell producing about 0.7 volts. Power electronics boost this to 400V AC through DC-DC converters and inverters. Battery buffers handle sudden load spikes and provide backup during hydrogen refueling—critical for applications like data centers where milliseconds matter. Safety systems include double-block-and-bleed hydrogen valves, explosion-proof enclosures, and continuous gas monitoring. These systems deploy rapidly: a standard 50kW unit fits in a shipping container and powers up in 30 minutes with no foundation required, making them ideal for emergency response or remote sites.

Performance Metrics That Matter for Operations

A 50kW hydrogen generator consumes precisely 0.8 kilograms of hydrogen per hour while producing zero emissions. Response times under 2 seconds allow instant adaptation to changing power demands—faster than diesel generators can spool up. These units operate at 45–50% electrical efficiency, comparable to conventional generators but without pollution. Noise levels stay below 65 decibels at one meter—quieter than normal conversation. Water production averages 0.67 liters per hour at full load, providing clean drinking water as a valuable byproduct in arid regions. During operation, you’ll notice only a faint hum from cooling fans and occasional condensation from the exhaust, a stark contrast to the vibration and fumes of diesel equipment.

Environmental Impact Comparison with Traditional Generators

Zero Emissions Versus Diesel Pollution

Every kilowatt-hour from a hydrogen generator eliminates 2.68 kilograms of CO₂ compared to diesel. Air quality impacts are dramatic: diesel generators contribute to approximately 36,000 premature deaths annually in the UK alone from NOx and particulate matter emissions. Hydrogen systems produce zero smog-forming pollutants, making them safe for indoor use at events or in food processing facilities. Unlike diesel exhaust—which contains carcinogens like benzene and formaldehyde—hydrogen generator exhaust is simply warm, clean water vapor. This eliminates respiratory health risks for workers on construction sites and allows deployment in emission-sensitive zones like national parks or urban centers.

Complete Lifecycle Sustainability

When powered by renewable electricity, hydrogen generators achieve true zero-carbon operation. Green hydrogen production via electrolysis creates no emissions when using solar or wind power. The water cycle remains closed—water splits during production and reforms during electricity generation. Compare this to diesel generators requiring constant fuel deliveries that risk spills and contaminate soil. Hydrogen generators also avoid the maintenance headaches of oil changes, filter replacements, and exhaust system cleanings. While battery storage systems degrade over time, hydrogen generator components like PEM membranes show degradation rates below 1 microvolt per hour—translating to decades of reliable service with minimal environmental impact.

Deployment and Future Outlook for Hydrogen Power

Modular Scaling for Any Application

Hydrogen generators scale seamlessly through standardized modules. Containerized 1MW electrolyzer skids allow rapid expansion from kilowatts to megawatts without redesign. Fuel cell units stack like building blocks—multiple 50kW modules combine to power everything from film sets to mining operations. This modularity enables precise capacity matching, avoiding the oversizing common with diesel generators. Cost trajectories show hydrogen production below €2/kg by 2030 through manufacturing scale-up and catalyst innovations. Recent projects demonstrate this scalability: a 2MW hydrogen generator now powers telecom towers across rural Africa, while 1MW units support grid stability in California during peak demand.

Maintenance and Reliability Advantages

Fuel cell generators require minimal maintenance—just air filter and coolant changes every 8,000 hours. No moving parts in the core power generation section eliminate mechanical wear, unlike diesel generators with complex engines. Predictive maintenance systems monitor performance metrics like voltage degradation, scheduling service before failures occur. Electrolyzer maintenance focuses on membrane replacement every 5-10 years and catalyst refurbishment. Automated monitoring tracks critical parameters in real-time, with cloud-based dashboards alerting operators to anomalies. In field tests, hydrogen generators achieve 98% uptime—significantly higher than diesel alternatives—because they avoid fuel gelling in cold weather and don’t require crankcase heaters in freezing conditions.

Key Takeaway: Understanding how a hydrogen generator works reveals why it’s transforming power generation. Whether creating hydrogen from renewable electricity or generating clean power from stored hydrogen, these systems offer silent, emission-free operation with minimal maintenance. The chemistry is elegantly simple: split water to store energy, recombine elements to release it. As costs continue dropping and efficiency improves, hydrogen generators will become the standard for clean, reliable power across industries—from replacing diesel on construction sites to providing emergency backup for hospitals. For immediate implementation, start with containerized 50kW units that deploy in 30 minutes; they require no special foundations and integrate seamlessly with existing electrical systems. The future of clean power isn’t coming—it’s already generating electricity quietly in locations worldwide.