When the power grid fails during a storm, your generator springs to life, silently converting mechanical motion into the electricity that keeps your refrigerator humming and lights glowing. But how does generator work to transform spinning motion into usable power? Whether it’s a compact camping unit or a massive power plant generator, every model relies on the same fundamental electromagnetic principle discovered in 1831. This guide explains exactly how generators transform mechanical energy into electrical energy, why different types exist for specific applications, and what keeps them running reliably for decades—without technical jargon or confusing physics equations.

The Electromagnetic Engine Behind Every Generator

Generators don’t create electricity—they force existing electrons to move through conductors. Understanding how does generator work starts with recognizing it’s an energy converter, not a creator. When you spin a coil of copper wire inside a magnetic field (or vice versa), the movement pushes electrons along the wire, generating usable electrical current.

Faraday’s Law in Real-World Operation

Michael Faraday’s 1831 discovery remains the foundation of every generator today. The key principle states that changing magnetic flux through a circuit induces voltage. In practical terms:

- Rotating a magnet inside stationary copper windings or

- Spinning copper windings inside a stationary magnetic field

Both approaches produce identical results: alternating current (AC) electricity flowing through your circuits.

This electromagnetic dance happens inside every generator, from the tiny unit powering your campsite to the massive turbines supplying city grids. The magic occurs because electrons already exist in the copper wire—they just need that magnetic “push” to start moving in a coordinated direction.

What Actually Spins the Generator Shaft

The mechanical force driving generator operation varies dramatically by application:

- Power plants: Steam, gas, or water pressure spins massive turbines

- Backup generators: Diesel, gasoline, or natural gas engines provide rotation

- Renewable systems: Wind or water current turns turbine blades

- Emergency use: Hand cranks or pedal power for small-scale needs

Regardless of the power source, the generator’s sole requirement is consistent rotational speed. In North America, generators must spin precisely at 3,600 rpm for 60 Hz output (or 1,800 rpm with 4-pole designs), while most other countries require 3,000 rpm for 50 Hz systems. This exact speed control ensures your electronics receive stable, compatible power.

Generator Types and Their Real-World Applications

AC Alternators: The Workhorses of Modern Power

Over 95% of the world’s electricity comes from synchronous generators (alternators). These units feature:

- A rotating electromagnet (rotor) powered by DC current

- Stationary copper windings (stator) that harvest the induced AC

- Precise speed control to maintain 50/60 Hz frequency

Large power plant alternators often use hydrogen cooling for efficiency, while smaller units rely on forced air. Their brushless design eliminates maintenance-intensive commutators, making them ideal for continuous operation in everything from hospitals to data centers.

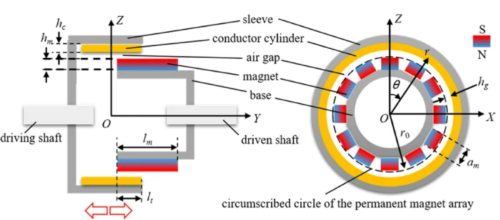

Permanent-Magnet Generators: Compact Power Solutions

When space and weight matter, permanent-magnet synchronous generators (PMSG) shine. These units replace electromagnets with powerful rare-earth magnets on the rotor, delivering:

- Higher efficiency (no energy lost to field excitation)

- Smaller physical size for equivalent output

- Instant voltage build-up without external power

You’ll find PMSG technology in modern wind turbines, hybrid vehicle regenerative braking systems, and premium portable generators where clean, stable power matters for sensitive electronics.

Induction Generators: The Grid-Dependent Option

Common in wind farms, induction generators operate differently—they require an existing power source to create their magnetic field. Key characteristics:

- No separate DC excitation system needed

- Must connect to an active grid or capacitor bank

- Allows variable rotor speeds while maintaining constant output frequency

Doubly-fed induction generators (DFIG) take this concept further, using power electronics to maintain stable grid connection even as wind speeds fluctuate—making them the dominant technology in utility-scale wind power.

Inside a Generator: Critical Components That Make It Work

The Prime Mover: Your Generator’s Muscle

Whether it’s a diesel engine in your backyard unit or steam turbine in a power plant, the prime mover provides the essential rotation. Critical considerations:

- Engine type determines fuel flexibility (diesel, propane, natural gas)

- Governor systems maintain precise rotational speed under varying loads

- Startup systems require reliable batteries (tested monthly) for automatic backup units

A generator only produces electricity when its shaft spins at the correct speed—making the prime mover the literal driving force behind how does generator work.

Voltage Regulation: Keeping Power Stable

Your electronics demand consistent voltage, which is why every generator includes sophisticated regulation:

- Automatic Voltage Regulators (AVRs) constantly monitor output

- Field current adjustments happen 50-60 times per second

- Precision control maintains voltage within ±1% from no-load to full capacity

Without this critical component, your generator’s output would fluctuate wildly as you turned appliances on and off—potentially damaging connected equipment.

Step-by-Step: How a Generator Produces Electricity

The Power Generation Sequence

- Startup phase: Battery engages starter motor, spinning the engine until it fires

- Excitation process: AVR supplies initial DC to rotor, creating magnetic field

- Induction begins: Rotating magnetic field cuts across stator windings

- Voltage build-up: Initial output feeds back to strengthen the magnetic field

- Stabilization: AVR fine-tunes field current until voltage reaches 120/240V

- Load acceptance: Transfer switch connects generator to your electrical panel

- Continuous operation: Engine governor and AVR work together to maintain stable power

This entire sequence happens in seconds for modern automatic units, with sophisticated models completing synchronization in under 10 seconds after detecting a power outage.

Why Frequency Matters More Than You Think

The relationship between rotational speed and electrical frequency is fixed by physics: f = (P × N) / 120 where:

– f = frequency in Hz (60 in North America)

– P = number of magnetic poles

– N = rotational speed in RPM

This explains why small portable generators must spin at 3,600 RPM (for 2-pole designs) to produce standard household power. Larger industrial units use more poles to achieve the same frequency at lower, more efficient speeds.

Critical Maintenance That Keeps Generators Running

The Top 3 Generator Killers (And How to Prevent Them)

-

Wet stacking (diesel units): Incomplete combustion from chronic underloading

→ Solution: Run monthly under 30-50% load for 30+ minutes -

Fuel degradation: Gasoline loses volatility in 30 days; diesel grows microbes

→ Solution: Add stabilizers and polish fuel annually -

Battery failure: 70% of automatic generator failures stem from weak batteries

→ Solution: Test monthly and replace every 3 years

Essential Maintenance Schedule

| Task | Frequency | Critical Warning Signs |

|---|---|---|

| Oil & filter change | Every 150-250 hours | Metallic particles, dark color |

| Air filter inspection | Weekly during use | Restricted airflow, visible dirt |

| Coolant level check | Before each use | Low levels, discoloration |

| Load bank test | Quarterly for critical systems | Voltage droop under load |

| Fuel system cleaning | Annually | Hard starting, reduced runtime |

Smart Generator Sizing: Avoiding Costly Mistakes

The 4-Step Sizing Process That Works

- List all essential loads with running and starting wattages (motors need 3-7x startup power)

- Calculate total demand including diversity factor (not everything runs simultaneously)

- Add 25% safety margin for future needs and voltage stability

- Verify altitude derating (lose 3-4% capacity per 1,000 feet elevation)

Most homeowners oversize by 30-50%, wasting fuel and money. A properly sized 7kW unit handles refrigerators, lights, well pumps, and furnace fans in most 2,000 sq ft homes—while a 22kW unit powers nearly everything except large central AC.

Generator Efficiency: What Manufacturers Won’t Tell You

Large power plant generators achieve remarkable 98% efficiency, but your portable unit tells a different story:

- 5-10kW portable units: 85-88% efficient (15-20% energy lost as heat)

- 20-50kW home standby: 90-92% efficient with liquid cooling

- 100kW+ commercial: 93-95% with advanced cooling systems

This efficiency gap explains why running a small generator for extended periods costs significantly more per kilowatt-hour than grid power. For occasional outages, this matters little—but for frequent or extended use, consider solar+battery alternatives.

The Hidden Lifespan of Your Generator

With proper care, generators deliver decades of service:

– Portable units: 1,000-2,000 hours (5-10 years with annual use)

– Home standby: 10,000-30,000 hours (25-40 years with maintenance)

– Power plant generators: 40+ years with major overhauls

The secret? Consistent maintenance focused on the big three: clean fuel, fresh oil, and regular exercise under load. Generators that sit unused develop more problems than those run weekly—even without load.

Understanding how does generator work transforms it from mysterious black box to reliable tool. When storms threaten, you’ll appreciate knowing exactly what keeps your power flowing—the elegant electromagnetic principle that converts spinning motion into life-sustaining electricity, one rotation at a time. Keep your fuel fresh, your oil clean, and your maintenance schedule current, and your generator will deliver dependable power exactly when you need it most.