Your generator sits silently in the garage until the lights go out—then it’s your lifeline. But when that critical moment arrives, nothing sabotages performance faster than neglected oil. Too many homeowners learn this lesson during a blackout when their machine sputters and dies. The truth? Oil change frequency isn’t guesswork—it’s dictated by hard runtime hours, environmental conditions, and unmistakable warning signs. Whether you own a portable camping unit or a whole-house standby system, this guide reveals exactly how often to change generator oil based on manufacturer specifications and real-world engineering data.

Ignoring oil maintenance risks catastrophic engine failure when you need power most. Fresh oil ensures proper lubrication, heat dissipation, and contaminant removal. This isn’t just about routine upkeep—it’s about guaranteeing your generator will roar to life during the next storm. You’ll discover precise intervals for every generator category, environmental factors that slash change schedules by 50%, and visual cues that demand immediate action regardless of your calendar.

Break-In Oil Change: Your Generator’s Most Critical Service

That initial oil change isn’t optional—it’s non-negotiable engine protection. Manufacturing leaves microscopic metal shavings, assembly lubricants, and protective coatings circulating in your generator’s engine. These contaminants act like sandpaper, accelerating wear during the critical break-in phase. Change oil immediately upon reaching the specified runtime hour mark—never wait for the calendar date.

Why Skipping Break-In Oil Guarantees Premature Failure

During break-in, oil loses up to 40% of its lubricating capacity as it captures metal particles from seating piston rings and bearings. That metallic “glitter” visible in drained oil? Those are particles that would otherwise grind against cylinder walls for hundreds of hours. Skipping this service invites catastrophic scoring of critical engine components.

Pro Tip: Always replace the oil filter simultaneously. Filters capture 75% of initial contaminants—reusing one defeats the entire purpose of the break-in change. For most residential units, perform this service between 8-50 runtime hours as specified in your manual.

Portable Generator Oil Change Schedules (Gasoline Models)

Small portable units demand the most frequent oil attention due to high-RPM operation and exposure to harsh environments. Their compact engines run hotter and work harder than standby systems, accelerating oil breakdown. Ignoring these intervals risks seizure during your next camping trip or emergency outage.

Small Portable Units (Under 3,000 Watts)

- First Change: 8-25 runtime hours (critical for new units)

- Ongoing Schedule: Every 20-50 hours of operation

- Absolute Maximum: 12 months regardless of use

- Red Flag: Oil turning black before 15 hours indicates overload or poor ventilation

Mid-Size Portable Units (3,000-7,500 Watts)

- Break-In Service: 25-50 runtime hours

- Standard Interval: Every 100 hours

- Calendar Cap: Annual change required even with minimal use

- Pro Tip: Double-check oil level before each use—portables consume oil faster under heavy loads

Why Portables Need More Frequent Changes: Air-cooled engines reach higher operating temperatures than liquid-cooled standby units, thinning oil viscosity and accelerating oxidation. Construction site dust and debris also contaminate oil 3x faster than in protected standby installations.

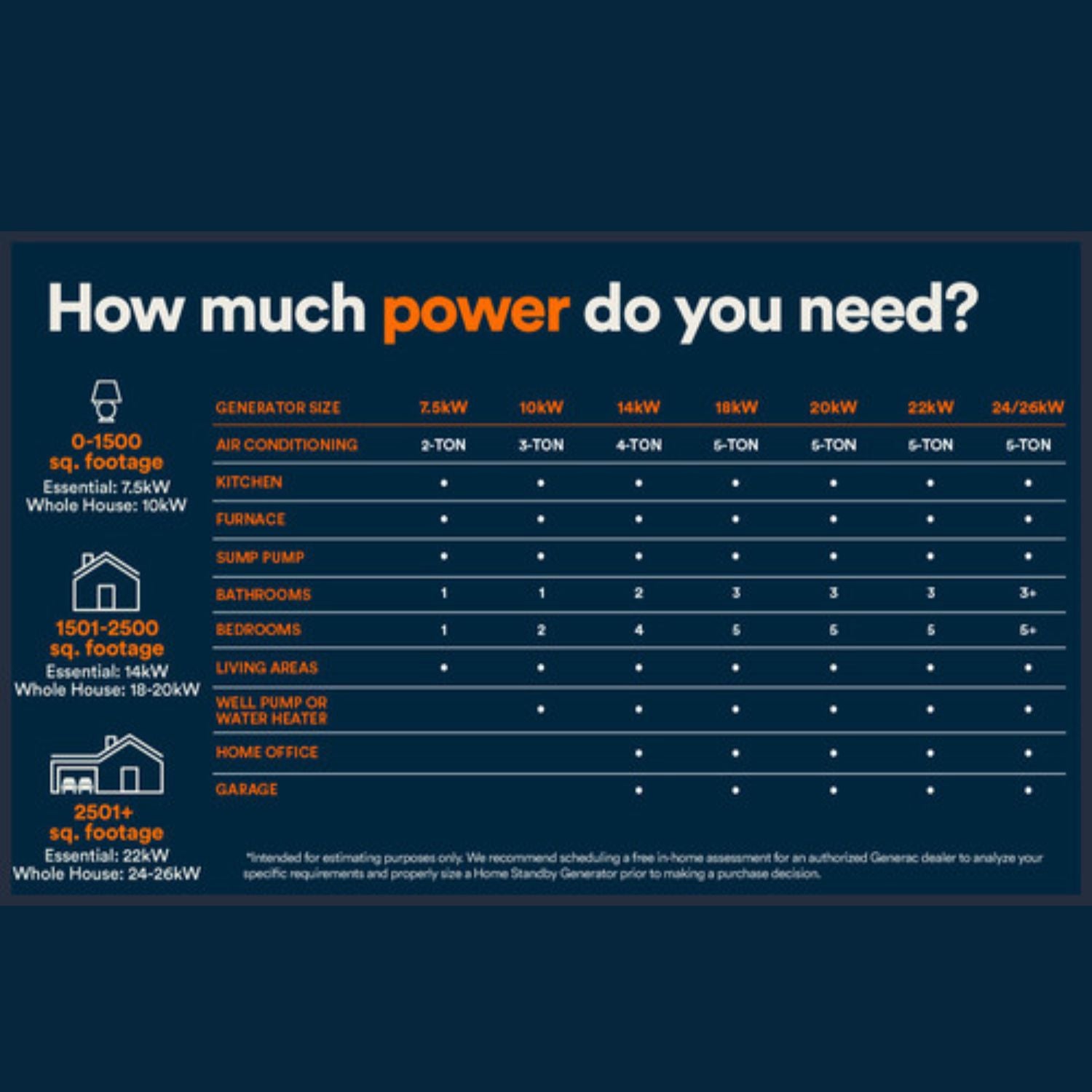

Standby Generator Oil Change Intervals (Whole-House Systems)

Residential standby generators follow more forgiving schedules but have stricter calendar requirements due to infrequent runtime. Most homeowners make a critical mistake—they assume “annual” means based on purchase date rather than operational hours. This misunderstanding voids warranties and causes preventable failures.

Gasoline/Propane/Natural Gas Standby Units

- Initial Service: 25 runtime hours

- Standard Schedule: Every 100-200 hours OR annually—whichever comes first

- Low-Use Exception: Oil analysis can extend beyond 12 months (see below)

- Critical Note: Generac 16kW units require oil changes every 200 hours

Diesel Standby Units (1,500 RPM Models)

- Break-In: 50 runtime hours

- Ongoing Schedule: Every 250 hours OR once yearly

- Prime Duty Extension: Up to 300 hours for continuous operation

- Warning: Diesel particulate matter contaminates oil faster—never exceed calendar limits

The Annual Deadline Trap: Standby units often run only 20-40 hours annually during self-tests. But oil degrades from moisture absorption and additive breakdown even when idle. Ignoring the 12-month cap causes acid formation that eats through bearings during your first real power outage.

Oil Analysis: Extending Change Intervals for Low-Use Generators

Facilities with standby generators increasingly replace fixed schedules with laboratory oil analysis—especially valuable for units running under 40 hours yearly. This isn’t DIY testing—it requires certified lab reports verifying oil remains serviceable.

How Oil Analysis Saves Money Without Risking Failure

- Collect 4 oz sample through drain plug while engine is warm

- Send to labs like Blackstone or Polaris for $30-$50 analysis

- Review critical metrics:

– Viscosity stability (must stay within SAE grade)

– Acid number (TAN below 2.0 is safe)

– Contaminant levels (silicon from dust, iron from wear) - Extend intervals up to 24 months if all parameters remain optimal

Warranty Protection: Major manufacturers like Cummins and Kohler accept lab results in place of annual changes. Always keep original reports—warranty claims require proof of oil condition at time of failure.

Environmental Factors That Slash Oil Life by 50%

Your location and operating conditions dramatically shorten oil change intervals. These factors turn a 200-hour schedule into a 100-hour requirement—ignoring them risks engine destruction.

Dusty Construction Sites and Desert Climates

Abrasive particles overwhelm air filters, turning oil into grinding paste. Change oil every 50-75 hours instead of 100. Install premium synthetic oil with enhanced detergents and upgrade to high-efficiency air filters (FRAM XG series).

Tropical Humidity and Coastal Regions

Moisture condensation creates emulsified oil that loses lubricity. Check dipstick weekly—milky appearance requires immediate change. Add 10% more frequent changes in environments above 80% humidity.

Extreme Temperature Swings

- Above 95°F: Oil thins excessively—reduce intervals by 25% and switch to higher-viscosity synthetic

- Below 32°F: Cold starts increase wear—use 5W-30 instead of 10W-30 and change oil before winter

Pro Tip: Generators in Phoenix, AZ need oil changes 30% more often than identical units in Seattle due to heat and dust exposure. Adjust schedules for your specific environment.

Emergency Warning Signs Requiring Immediate Oil Change

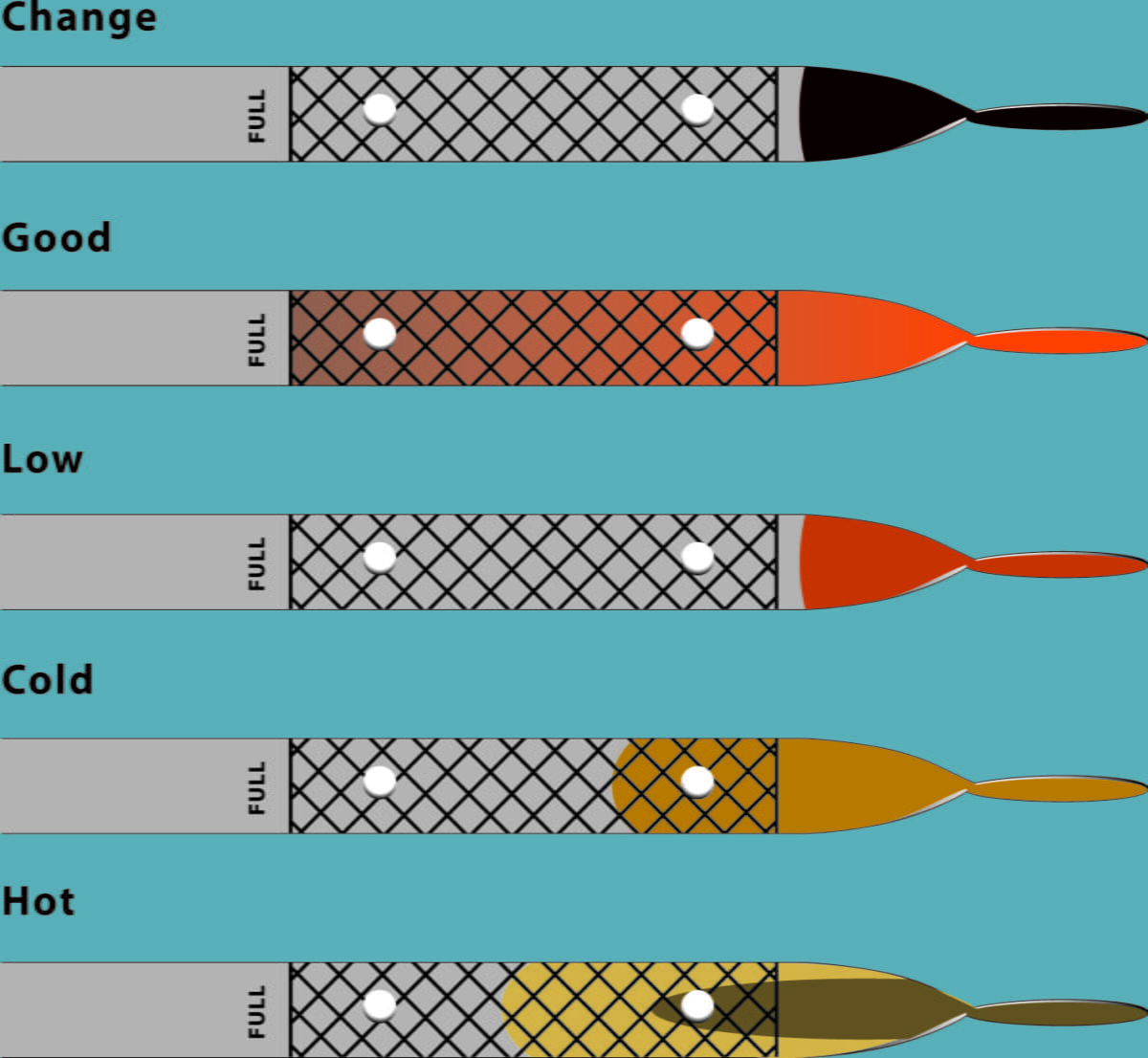

Your oil dipstick tells a story—learn to read it. These visual indicators override all schedules and demand action within 24 hours to prevent engine destruction.

Metallic Particles: The “Glitter Death” Signal

Visible metallic flecks indicate catastrophic internal wear. Change oil immediately and inspect for:

– Aluminum glitter: Piston ring wear

– Steel flakes: Bearing failure

– Copper shards: Bushing damage

Burnt Oil Smell and Overheating

A pungent, acrid odor means oil has lost cooling capacity. Shut down immediately—running with degraded oil melts piston rings within minutes. Top off only for emergency power restoration, then perform full service.

Critical Check: Rub oil between fingers—if gritty texture appears, change oil before next use regardless of hour count. Clean oil should feel silky smooth.

Step-by-Step Oil Change: Avoiding Costly Mistakes

Most generator failures during oil changes stem from preventable errors. Follow this exact sequence to avoid warranty-voiding mistakes.

Filter Replacement: The #1 Warranty Killer

- Never reuse oil filters—even “low-hour” units require new filters

- Hand-tighten only (overtightening cracks housings)

- Pre-fill new filter with oil to prevent dry-start damage

Drain Plug Protocol

- Replace crush washers every time (leaks cause 68% of oil-related failures)

- Torque to manufacturer specs (typically 15-20 ft-lbs)

- Position drain pan BEFORE removing plug—spills void warranties

Pro Tip: Run generator 2 minutes after refill, then recheck level. Air-cooled engines require topping off as oil circulates to upper cylinder areas.

Storage Rules That Preserve Oil Between Outages

Infrequent use creates unique oil degradation risks. Follow these protocols whether storing for 3 months or 3 years.

Short-Term Storage (1-6 Months)

- Run under load for 15 minutes monthly to circulate fresh oil

- Never store with fuel—ethanol degrades seals and contaminates oil

- Check dipstick for milky residue before next use

Long-Term Storage (6+ Months)

- Change oil BEFORE storage to remove combustion acids

- Fog cylinders with fogging oil through spark plug hole

- Store with battery maintainer connected

Critical Note: Oil left in crankcase during storage absorbs moisture from temperature swings—this causes sludge that blocks oil passages during first startup.

Final Reality Check: Your generator’s reliability during the next blackout depends entirely on oil changed at the right time. Portable units need service every 20-100 hours. Standby systems demand annual changes or 100-200 runtime hours—whichever comes first. Environmental factors can slash these intervals by half. Most importantly: never ignore metallic particles or burnt smells. Check your hour meter today, inspect your oil’s color and texture, and schedule maintenance before the next storm hits. Waiting until power fails guarantees you’ll be sitting in the dark with a seized engine—while your properly maintained neighbor’s generator hums through the outage. Change oil on schedule, and your generator will deliver when seconds count.