Your lights flicker, then die. The fridge stops humming. In that split-second power failure, you realize how much you rely on electricity—until you hear the reassuring rumble of your gas generator kicking in. Whether protecting your family during storms or keeping your business operational, learning how to choose a gas generator correctly impacts your safety, comfort, and wallet for 15-20 years. This guide cuts through the confusion with actionable steps to match your exact needs to the right unit—no fluff, just critical decision points verified by industry standards. You’ll discover why 68% of generator failures stem from improper sizing and fuel mismatches, and how to sidestep these expensive errors before wiring a single connection.

Pinpoint Your Generator’s Mission-Critical Purpose

Skip this step, and you’ll waste thousands on mismatched equipment. Standby generators automatically restore power within seconds of outages for homes or hospitals, while continuous prime power units serve as primary electricity for off-grid sites running 24/7. Peak shaving models intentionally operate during high-utility-rate periods to slash commercial electricity bills—requiring sophisticated load management. Your facility’s critical loads dictate everything: A data center must maintain server cooling without interruption, whereas homeowners prioritize refrigeration and well pumps. Crucially, verify acceptable downtime—medical facilities need near-zero transfer time via UPS integration, while most homes tolerate 10-second delays. Ignoring emissions regulations also risks rejection; urban installations often require CARB Tier 4 compliance.

Standby vs. Prime Power: The Costly Confusion

Many homeowners accidentally buy portable units for whole-house backup, only to face dangerous overload trips during storms. True standby generators like Briggs & Stratton’s 40369 (13.5 kW NG) permanently integrate with your electrical panel through automatic transfer switches, self-testing weekly to ensure readiness. Conversely, light industrial units like Cummins’ 60 kW QuietConnect handle telecom site prime power with 500-hour oil change intervals—critical if you’ll run daily, not just during emergencies.

Match Generator Type to Your Exact Application

Gas generators aren’t one-size-fits-all. Home standby models (6-25 kW) like Generac’s 22kW unit connect directly to natural gas lines, operating at 55-62 dB(A)—quieter than conversation. Commercial units (25-150 kW) feature load-shedding controllers for retail stores and 277/480V three-phase power. Portable gas generators (3-12 kW) offer mobility but lack automatic transfer switches, making them dangerous for whole-house backup. Most critically, natural gas generators dominate 40-80 kW applications where pipeline access exists, offering 25-40% lower operating costs than propane alternatives.

Why Portable Gas Units Fail for Permanent Backup

That $800 portable “dual-fuel” generator won’t protect your home during extended outages. Most require manual startup, lack safety interlocks, and derate 5-10% when converted to propane via aftermarket kits. Worse, they exhaust deadly carbon monoxide into living spaces if improperly positioned—a leading cause of generator-related fatalities.

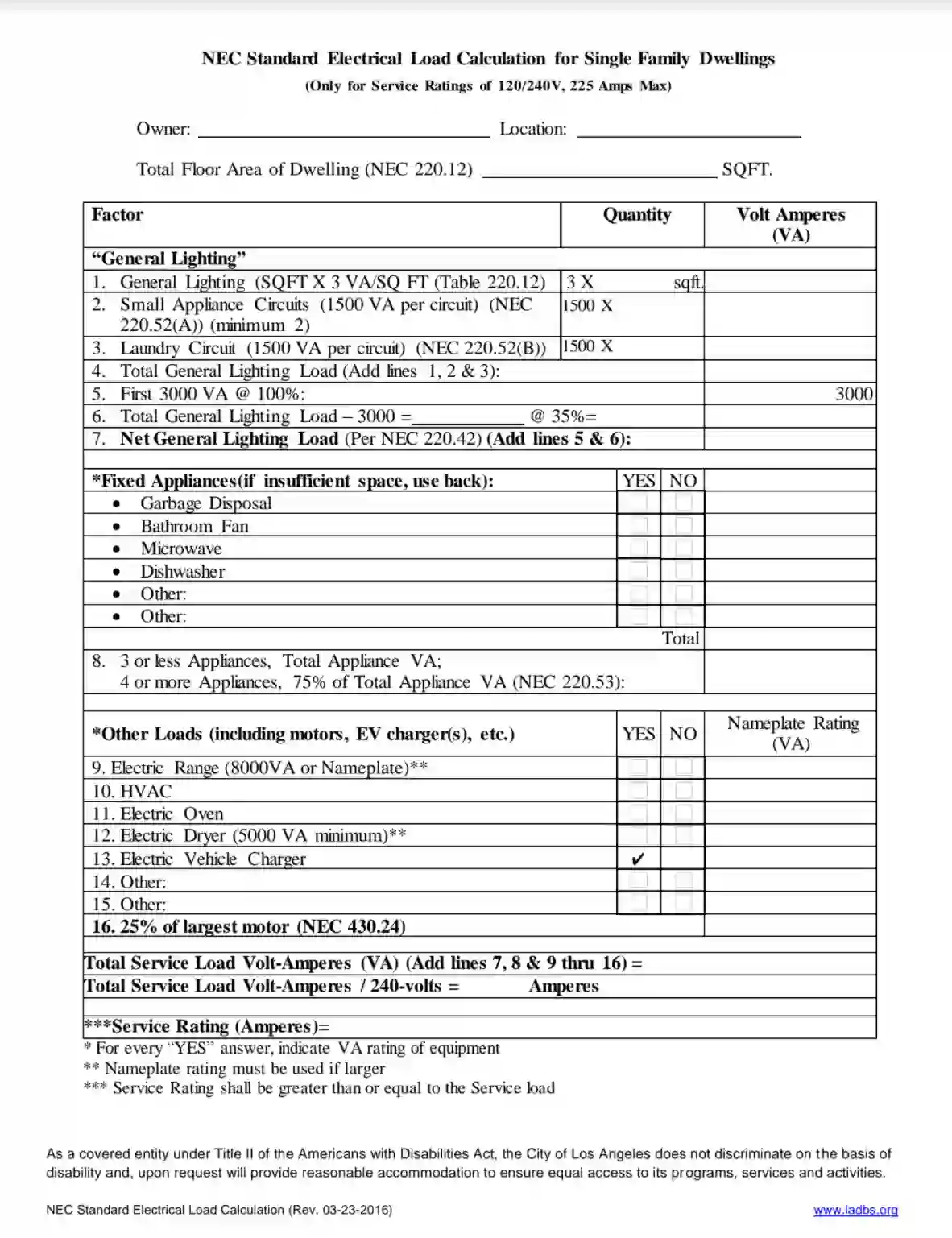

Calculate Power Needs Like a Professional

Undersizing destroys compressors; oversizing wastes 20% of your budget. Start by listing every device’s running watts and locked-rotor surge watts (e.g., 3-ton A/C: 3,500W running / 15,000W surge). Apply a 0.7-0.9 diversity factor since not all devices start simultaneously, then add 25% growth margin for future expansion. Crucially, derate for environmental factors: gas engines lose 3% power per 1,000 feet altitude and 1% per 10°F above 77°F.

Real Sizing Example: Avoid the 10,500W Surge Trap

Consider these common loads:

– Refrigerator: 700W running / 2,200W surge

– Well pump (½ HP): 1,000W running / 3,000W surge

– Lighting/outlets: 3,000W continuous

Total running watts: 6,500W. Total surge: 10,500W.

With 25% safety margin, you need 13,125W continuous rating—requiring a 14-16 kW standby unit. A 12 kW model would trip instantly when the A/C compressor kicks on.

Fuel Selection: Pipeline Gas vs. Propane Tank Reality Check

Natural gas generators win long-term where pipelines exist, costing 25-40% less per kWh than propane. Verify your meter’s capacity early—upgrades add weeks to projects. A 14 kW unit needs 1-¼ inch gas piping for 50-foot runs at standard 4-7 inch water column pressure. Propane requires 500-gallon tanks (costing $1,200-$2,500 installed) for meaningful runtime; that same 14 kW unit burns 1.89 gal/hr at 50% load, giving just 264 hours from a full tank. In cold climates below -20°F, propane vaporization fails without heated tanks—adding $500-$1,000 to your budget.

The Hidden Cost of Fuel Switching

Dual-fuel conversion kits for portable generators seem convenient but reduce output by 5-10%. A 12,000W gasoline unit becomes an 11,000W natural gas generator—potentially insufficient during peak demand. Pipeline gas also rarely fails except during major earthquakes, while propane deliveries get delayed in storms.

Decode Manufacturer Specs That Actually Matter

Don’t get fooled by “peak watt” marketing. Focus on continuous kilowatt ratings matching your load list plus margin. For sensitive electronics like medical equipment, demand <5% Total Harmonic Distortion (THD)—found in Briggs “Synergy” or Cummins “QuietConnect” alternators. Noise levels must comply with local ordinances; most residential areas cap at 65 dB(A) at 23 feet, but premium units hit 55-62 dB(A). Crucially, confirm voltage configuration: homes need 120/240V single-phase, while commercial buildings require 277/480V three-phase—field modifications cost thousands.

Engine Quality: The 10-Year Reliability Factor

Air-cooled OHV engines (like Briggs Vanguard) suffice for residential standby under 25 kW, but liquid-cooled units (Generac G-Force, Kohler KDI) dominate commercial applications. They run cooler, quieter, and double oil change intervals to 500 hours—slashing long-term maintenance. Check warranty fine print: residential units typically offer 3-5 years, while commercial models cover 2-3 years or 1,500 hours.

Installation Pitfalls That Void Warranties

NFPA 37 mandates 5 feet clearance from wall openings and 3 feet from combustible surfaces—ignoring this risks fire and invalidates insurance. Your concrete pad must support immense weight: a 14 kW air-cooled unit weighs 450 lbs, while 48 kW liquid-cooled models hit 1,600 lbs. In cold climates, skip battery warmers and oil heaters at your peril; they enable -40°F starts but add $800-$1,500. Electrical bonding is non-negotiable—NEC 250.30 requires proper neutral-ground separation for separately derived systems.

The Transfer Switch Trap

Manual transfer switches save $500 but require you to be home during outages—useless for vacation homes. Automatic Transfer Switches (ATS) like Generac’s 200A model cost $1,200-$2,000 but activate within 10 seconds. Ensure it’s service-entrance rated; sub-panel switches overload during whole-house power restoration.

10-Year Cost Analysis: Natural Gas vs. Propane

A 20 kW natural gas standby system costs $9,700 installed. Annual operating costs? Just $190 in fuel (80 hours × 206 cu. ft./hr × $1.10/therm) plus $130 in maintenance—totaling $3,200 over a decade. Propane equivalents burn $320/year in fuel (2.3 gal/hr × $3.50/gal) and cost more for tank rentals, pushing 10-year OPEX to $4,500+. Factor in AGM battery replacements every 2 years ($150 each), and the savings compound.

Maintenance Secrets for 20,000-Hour Lifespans

Residential units need oil/filter changes every 100 hours, but commercial liquid-cooled models stretch to 500 hours. Weekly 20-minute auto-exercises prevent “wet stacking” (fuel buildup from underloading). In dusty areas, clean air filters monthly—not annually—to avoid 15% power loss.

Your 8-Step Gas Generator Selection Checklist

Follow this sequence religiously:

1. Define need: Standby, prime, or peak shaving?

2. Match category: Home vs. commercial vs. portable

3. Calculate kW: Load list + surge + 25% margin + altitude derating

4. Verify fuel: NG pipe sizing vs. LP tank capacity

5. Check codes: Noise limits, emissions, setbacks

6. Select model: THD <5%, correct voltage, commercial engine

7. Plan installation: Pad specs, ATS type, cold-weather kits

8. Book commissioning: Factory-authorized startup validates warranty

Critical First Moves to Avoid Regret

Start with a free professional load assessment from authorized dealers like Cleveland Brothers—they catch 92% of sizing errors before purchase. Immediately confirm natural gas meter capacity with your utility; insufficient pressure causes chronic underperformance. Budget 15% above unit cost for proper installation, including transfer switches and gas plumbing. For commercial use, invest in extended warranties covering labor—repair costs average $400/hour. Finally, leverage 0% APR financing on residential packages; Generac and Briggs & Stratton offer 24-month terms making whole-house protection affordable upfront.

Your gas generator isn’t just equipment—it’s your lifeline during chaos. By methodically matching purpose, power, and fuel to your reality, you’ll transform anxiety into assurance every time the lights go out. The right unit pays for itself in one severe storm; the wrong one becomes a costly paperweight. Take these steps now, and for 15 years, you’ll hear not panic, but the steady hum of security.