Your Champion generator refuses to start after months in storage. You pull the cord repeatedly, but it sputters and dies—classic carburetor gumming. This happens to thousands of generator owners every season when ethanol-blended fuel leaves sticky deposits that clog microscopic passages. When your power goes out during a storm, you can’t afford to wait for a service technician. This comprehensive guide walks you through the exact steps to restore your generator’s performance without expensive shop visits.

Whether you own a traditional open-frame Champion or modern inverter model, these proven techniques work across the entire product line. You’ll need about 45 minutes and basic tools most homeowners already have. Let’s get your generator running like new again so you’re prepared for the next power outage.

Critical Safety Steps Before Carburetor Service

Never rush the preparation phase—most generator injuries happen during maintenance, not operation. Start by moving your generator outdoors to a well-ventilated area. Fuel vapors accumulate quickly in garages and sheds, creating both health risks and fire hazards. The knowledge base emphasizes this as a critical first step to avoid dangerous vapor accumulation.

Complete shutdown sequence you must follow:

– Turn off fuel valve and let engine run until it stops

– Allow engine to cool completely (minimum 30 minutes)

– Disconnect spark plug wire from spark plug

– Position wire away from plug to prevent accidental contact

Remove all combustible materials within 10 feet—rags, papers, gasoline containers, even dry leaves. Wear chemical-resistant gloves and safety glasses throughout the process. These simple precautions prevent 90% of maintenance-related accidents. Remember, Champion Power Equipment explicitly states you must never attempt carburetor service while the engine is running due to extreme danger from moving parts and potential fuel ignition.

Gather Champion-Specific Tools and Supplies

Gather everything before starting—interruptions during carburetor cleaning lead to lost parts and confusion. Champion generators use standard carburetor components, but model-specific variations exist.

Essential toolkit:

– Phillips and flathead screwdrivers (multiple sizes)

– Needle-nose pliers and regular pliers

– Clean rags and small wire brushes

– Compressed air or aerosol air duster

Cleaning supplies:

– Carburetor cleaner spray (genuine brand recommended)

– Small container for soaking parts

– New carburetor rebuild kit (gaskets, o-rings, needle valve)

– Fresh, ethanol-free gasoline for testing

Pro tip: Buy genuine Champion parts online using your model number. Aftermarket kits often contain slightly different gaskets that leak or fail prematurely, causing you to repeat the entire cleaning process.

Locate Your Champion Generator’s Carburetor

Champion generators position carburetors differently based on model type. Open-frame generators typically mount the carburetor on the engine’s side, protected by a rectangular air filter housing. Inverter models often conceal the carburetor beneath plastic covers for noise reduction.

Quick identification method:

– Follow the air filter box to the engine

– Carburetor sits between air filter and engine block

– Look for fuel line and throttle linkage connections

Remove air filter housing by loosening thumb screws or Phillips screws. Note the air filter orientation—installing it backwards reduces airflow and performance. Take photos with your phone during disassembly; these visual references prevent reassembly mistakes that could leave you stranded without power.

Proper Fuel System Shutdown Procedure

Prevent gasoline spills by properly depressurizing the fuel system. Turn the fuel valve to “OFF” position—usually located below the fuel tank on the fuel line path. Start the generator and let it run until fuel starvation stops the engine. This burns remaining fuel in carburetor bowl, reducing spillage during removal.

Fuel valve locations by Champion model:

– Traditional generators: Red lever below fuel tank

– Inverter models: Small petcock near carburetor

– Dual-fuel units: Multiple valves—close gasoline side only

Place absorbent rags beneath the carburetor area. Small amounts of fuel inevitably spill during bowl removal, and gasoline damages painted surfaces and plastic components instantly. This step aligns with Champion Power Equipment’s safety requirements for working with fuel systems.

Remove Carburetor Components Without Damage

Modern Champion carburetors use simple mounting systems, but hidden connections cause frustration. Work methodically to avoid forcing components.

Step-by-step removal:

1. Disconnect fuel line using pliers on spring clamp

2. Remove throttle linkage rod (note hole position)

3. Unhook choke linkage if equipped

4. Loosen carburetor mounting bolts/nuts

5. Gently wiggle carburetor free from intake manifold

Critical observation: Champion uses both studs and bolts—keep track of which holes contained studs versus bolts. Mixing them during reassembly creates vacuum leaks and poor performance that mimics carburetor problems.

Disassemble Carburetor for Complete Cleaning

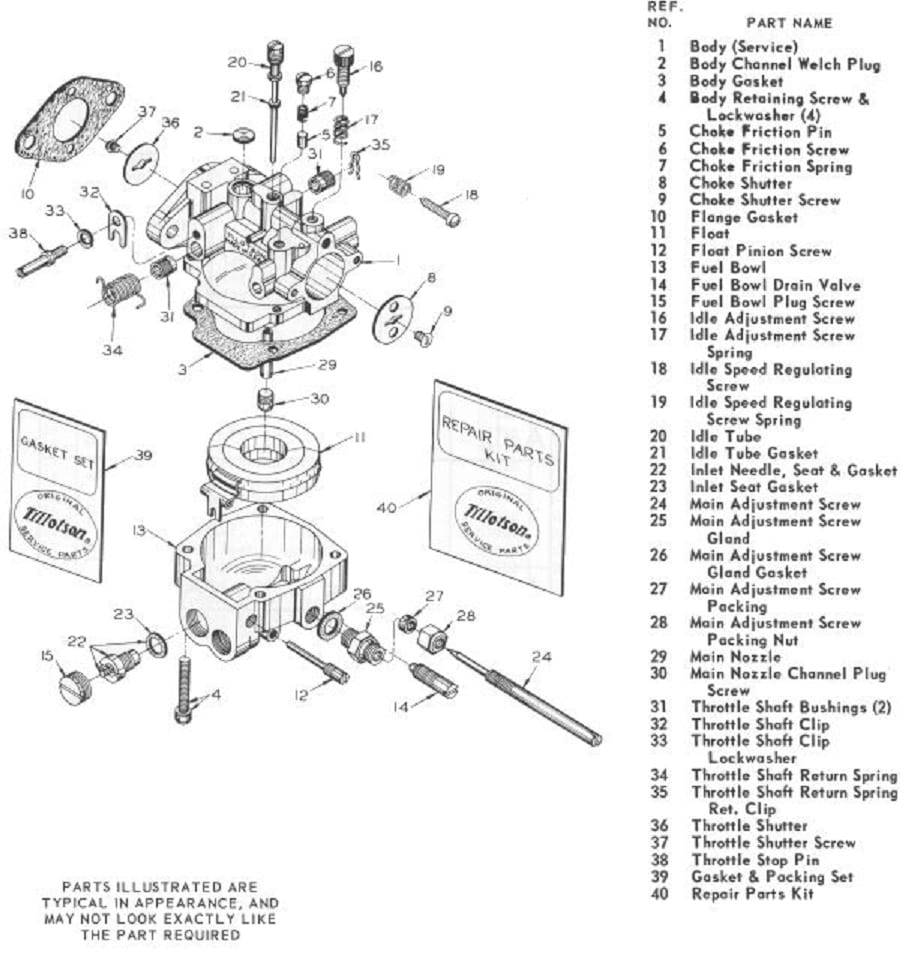

Carburetors contain tiny passages and precision components—organize parts systematically to prevent loss or confusion. Champion generators use standard float-type carburetors that require careful disassembly.

Bowl removal technique:

– Place carburetor on clean rag

– Remove bowl drain screw (if equipped) to empty residual fuel

– Loosen bowl screws in crisscross pattern

– Lift bowl straight down—avoid tilting to prevent gasket damage

Parts organization system:

– Use muffin tin or ice cube tray for small parts

– Label sections: Main body, float assembly, jets, gaskets

– Keep screws with their corresponding components

Take detailed photos of float position and jet locations. Champion uses different jet sizes for various models—mixing them creates running issues you can’t diagnose later.

Why Cleaning the Idle Circuit Solves Most Starting Problems

The idle circuit is the most common failure point in stored generators. This microscopic passage regulates fuel at low RPMs and clogs first when fuel evaporates. Use carburetor cleaner spray followed by compressed air through the idle jet until fluid flows freely. If you don’t see fluid exiting the other end, repeat the process. Many users mistakenly believe their carburetor needs replacement when cleaning this single passage would have solved the problem.

Deep Clean All Carburetor Passages Properly

Gum and varnish build up in microscopic passages invisible to naked eye. Thorough cleaning restores original performance. Champion generators are particularly susceptible to ethanol-related gumming when stored with fuel.

Cleaning sequence:

1. Spray carburetor cleaner through main jet from bowl side

2. Clean idle jet and air passages with compressed air

3. Soak metal parts in cleaner for 15 minutes

4. Use soft brush on exterior surfaces only

5. Blow compressed air through all passages until clear

Problem areas to check:

– Main jet: Center brass piece in bowl—ensure cleaner sprays freely through

– Idle circuit: Small hole near throttle plate—often completely blocked

– Float needle: Rubber tip must move smoothly without sticking

Never use wire or metal tools on jets—it enlarges passages permanently, creating rich-running conditions that waste fuel and foul spark plugs. This damage often requires complete carburetor replacement.

Inspect and Replace Worn Parts After Cleaning

Cleaning reveals component wear invisible when assembled. Check these specific areas for Champion carburetors:

Float inspection:

– Plastic floats: Look for cracks or fuel absorption (heavier than new)

– Brass floats: Shake gently—rattling indicates internal failure

– Float height: Measure 11/64″ from bowl gasket surface (varies by model)

Gasket condition:

– Bowl gasket: Replace if compressed, cracked, or torn

– Intake gasket: Check for vacuum leaks around mounting surface

– Needle valve seat: Replace if worn or scored

Order genuine Champion rebuild kits using your generator’s model and spec numbers. Generic kits often omit critical o-rings specific to your carburetor version.

Reassemble Carburetor with Champion Specifications

Reverse disassembly process, but with critical attention to detail. Small mistakes create big problems on first startup. Champion generators are sensitive to improper carburetor assembly.

Assembly sequence:

1. Install new gaskets dry—no sealant needed

2. Position float needle correctly on float tang

3. Torque bowl screws evenly—Champion specification is 25-30 inch-pounds

4. Verify float moves freely without binding

5. Install jets finger-tight plus 1/8 turn with proper tool

Final checks:

– All linkages move smoothly

– Throttle returns to idle position

– No fuel leaks from bowl gasket

– Air filter housing seals properly

Test linkages before installation—bent or misaligned linkages cause hunting or surging that appears to be carburetor problems.

Test Your Champion Generator After Carburetor Cleaning

Proper reinstallation prevents vacuum leaks and ensures reliable starting. Take time aligning components correctly.

Initial startup procedure:

– Turn fuel valve to “ON”

– Wait 30 seconds for bowl to fill

– Choke fully closed for cold start

– Pull cord smoothly—avoid yanking

– Gradually open choke as engine warms

Performance verification:

– Smooth idle without surging

– Quick response to load changes

– No fuel leaks or odors

– Normal exhaust color (clear to light gray)

Run the generator for 10-15 minutes under load to verify stable operation. Minor adjustments may be needed as engine reaches operating temperature.

Prevent Future Carburetor Problems in Champion Generators

Regular maintenance eliminates 90% of carburetor issues. Implement these habits immediately after successful cleaning.

Storage preparation:

– Run generator monthly for 15 minutes under load

– Add fuel stabilizer to fresh gasoline

– Drain carburetor bowl before extended storage

– Store with empty tank when possible

Fuel quality standards:

– Use ethanol-free gasoline when available

– Replace fuel every 30 days during storage season

– Install inline fuel filter for additional protection

– Keep fuel containers sealed and cool

Your Champion generator will provide years of reliable service with proper carburetor maintenance. The 45 minutes spent cleaning saves hundreds in professional repairs and ensures power availability during emergencies.

Key takeaway: Carburetor cleaning isn’t complex—it’s systematic. Follow these steps exactly, use genuine parts, and your Champion generator will start reliably every time you need it. Implement proper fuel storage practices to avoid repeating this process more than once a year, keeping your backup power ready when the grid fails.