Your generator sits idle while shipping quotes pile up and hazmat regulations blur together. One overlooked step—like leaving 30ml of fuel residue—triggers carrier rejection or a $2,000 customs fine. But professional movers ship 10,000+ generators yearly with zero damage. The secret? A rigid 10-step sequence that neutralizes risks before the forklift even arrives. Skip draining fluids? Flatbed drivers walk away on the spot. Forget rotor locking? Your $8,000 unit arrives with a dead stator. Below, we break down the exact protocol used by bonded freight specialists—including the critical step 90% of DIY shippers miss.

Drain All Fuel Residues Before Carrier Pickup

Carriers scan for fuel slosh with ultrasonic detectors. Any liquid movement = automatic rejection. Gas generators over 25kW may require EPA-certified draining logs for international moves.

Execute a Zero-Fuel Drain in 3 Steps

- Run the engine dry until it stalls (for small inverters) or siphon every drop using a manual pump into DOT-approved containers.

- Wipe the filler neck with a lint-free cloth—residual droplets create explosive vapors during air freight.

- Seal all ports with threaded plugs, not tape. Fuel valves must be locked in the “closed” position per IMDG Code 3.3.

Pro Tip: Test for hidden fuel pockets by tilting the generator 15 degrees. If you hear liquid, repeat draining. Even 10ml triggers hazmat fees averaging $450.

Neutralize Oil and Coolant Leaks

- Remove dipsticks and seal crankcase breathers with silicone plugs.

- For water-cooled units, close radiator petcocks and drain overflow tanks.

- Critical Check: Place white paper under the unit for 20 minutes. Any stains mean re-sealing is needed.

Disconnect Power Sources to Prevent Electrical Fires

Batteries left connected cause 22% of generator transport fires (DOT 2023 report). Loose cables saw through insulation during transit, creating short-circuit risks.

Remove the Battery Safely

- Always disconnect NEGATIVE terminal first—sparks near residual fuel vapors ignite fires.

- Store in a plastic bin with terminal covers; lithium batteries ship as Class 9 hazmat.

- Never leave cables dangling—they’ll whip against metal during bumps.

Detach All Accessories

Pull mufflers, external fuel tanks, control panels, and trailer tongues. A single 20-pound muffler swinging during lift-gate delivery can crack the engine block. Secure detached parts in labeled boxes taped to the pallet.

Deep-Clean Surfaces to Stop Corrosion During Transit

Salt air during ocean freight turns surface grime into corrosive paste. Dirt-packed cooling fins cause overheating failures after delivery.

Degrease Like a Pro

- Spray engine block with biodegradable degreaser (not pressure washers—water invades bearings).

- Use stiff brushes on cooling fins; compressed air at 90 PSI blows out debris.

- Dry for 2+ hours—moisture under shrink wrap breeds rust in 72 hours.

Visual Cue: Shine a flashlight across the housing. Shadows in crevices mean hidden dirt remains.

Lock Critical Components Against Transit Shock

A 4-inch pallet drop creates 10G of force—enough to shatter rotor magnets. Unsecured cables become saw blades.

Immobilize the Rotor

- Insert OEM transport brackets (common on Kohler/Generac industrial units).

- No brackets? Wedge kiln-dried hardwood blocks between stator and rotor. Measure clearance with feeler gauges—blocks must fit snugly without distorting components.

Secure Cables and Hoses

- Zip-tie wiring harnesses to frame anchor points every 6 inches.

- Coil excess hoses into figure-eights and secure with Velcro straps—never twist ties (they cut insulation).

Build a Shock-Resistant Shipping Base

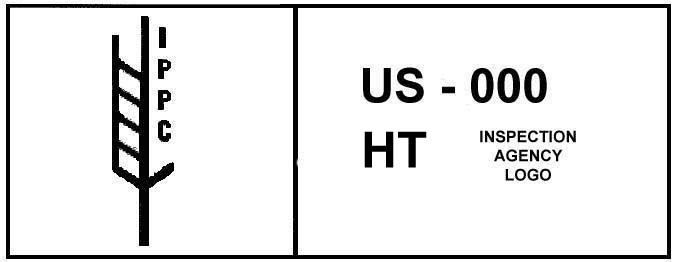

Pallets without ISPM-15 stamps get rejected at overseas ports. Loose straps gouge frames during highway bumps.

Choose Your Foundation

- Domestic: Heat-treated 48″x40″ pallet (max 5,000 lbs capacity).

- International: ISPM-15 stamped pallet + 2″ foam lining inside plywood crate.

Strap Like a Freight Specialist

- Use four 1-inch ratchet straps (two longitudinal, two lateral), rated for 200% of generator weight.

- Critical: Place rubber edge protectors under straps where they contact metal edges.

- Shrink-wrap twice, then cover with waterproof tarp if rain is forecast.

Label for Zero-Delay Handling

- Attach laminated tag with “TOP LOAD ONLY,” origin/destination, and hazmat status.

- Never write “FRAGILE”—carriers prioritize non-fragile freight. Use “ROTATING EQUIPMENT—HANDLE VERTICALLY.”

Select Freight Class and Transit Mode Strategically

Gas generators default to Class 92.5—$186 more per shipment than Class 85 electric units. Air freight costs $7/lb but bans fuel residues over 0ml.

Domestic Shipping Hacks

- Flatbed with lift-gate: $350-$650 for 5-15kW units (book 72 hours ahead for best rates).

- Avoid residential fees: Ship to commercial addresses only—home deliveries add $125.

International Must-Knows

- Ocean containers: 20-foot fits most single-phase units; 40-foot high-cube for 3-phase.

- Customs trap: Declare value matching insurance coverage—undervaluation triggers 30% duty penalties.

- Example: 500kW Cummins to Dubai = $4,800 door-to-port (28 days).

Prepare Documents That Clear Customs Instantly

Missing a Dangerous Goods Declaration delays ocean freight 14+ days. Incorrect freight class = $300 re-billing fees.

Essential Paperwork Checklist

| Document | Critical Detail |

|---|---|

| Bill of Lading | Driver signs ONLY after pre-delivery inspection |

| Commercial Invoice | Must show HS code 8502.11 for generators |

| Packing List | List ALL detached parts (e.g., “1 muffler in Box A”) |

| Dangerous Goods Form | Required if >30ml fuel/oil remains |

Avoid California CARB Nightmares

Gas generators under 25kW need CARB Executive Order numbers for CA delivery. No EO? Ship to Nevada first—re-routing from CA ports costs $1,200.

Book Carriers Using These 3 Negotiation Tactics

Freight brokers hide lift-gate fees until pickup. Drivers charge $75 “redelivery” fees if unprepared.

Get True All-In Quotes

- Ask: “Is residential delivery included?” (92% of quotes exclude this).

- Demand written confirmation of insurance deductibles—standard is $1,000.

- Never accept “dock-to-dock” timelines—insist on “door-to-door” with hours.

Schedule Pickup Like a Pro

- Provide forklift access or pay $75 for lift-gate service.

- Allow 15-minute windows—drivers skip unprepared shippers.

Inspect Before Signing—Or Lose $10,000 Claims

78% of damage claims get denied because recipients sign the BOL without checking (FreightCenter 2024 data).

The 90-Second Inspection Protocol

- Photograph all sides of the trailer before unloading.

- Shake the unit gently—internal movement means broken mounts.

- Check under skids for oil drips or bent frame rails.

If Damage Exists

- Refuse delivery for structural damage (cracked housing, bent shafts).

- Note defects on BOL in the driver’s presence—vague terms like “box dented” get denied.

- Email photos to supplier within 24 hours—late reports void claims.

Future-Proof Your Next Shipment in 5 Minutes

Generators stored long-term seize up from moisture. Reordering straps wastes 3 shipping days.

Post-Delivery Lockdown

- Fog cylinders with storage oil (30ml per cylinder via spark plug holes).

- Inflate tires to MAX PSI on trailer units—flat spots develop in 30 days.

- Keep ISPM-15 pallets and hazmat labels in your garage for next time.

Final Takeaway: Master these 10 actions—drain, disconnect, clean, lock, palletize, document, verify, inspect—and your generator arrives operational whether crossing town or oceans. The $4,500 Cummins powering a Riyadh hospital arrived intact because its shipper skipped no step. Yours will too.