Your ozone generator just died mid-cycle—no blue glow, no distinctive smell, and that critical disinfection job is stalled. Before you assume it’s totaled, 80% of ozone generator troubleshooting cases involve simple fixes you can complete in under 15 minutes. Whether you’re maintaining a spa, treating medical equipment, or purifying air in a flood-damaged property, this guide delivers precise diagnostics and solutions for every failure mode. Stop guessing and start fixing with these field-tested procedures.

Immediate Power Failure Diagnostics

Why Your Ozone Generator Won’t Power On (And Immediate Fixes)

When your unit sits completely dark, begin with the most common culprits that waste hours of unnecessary panic. First, physically unplug and reconnect the power cord at both ends—many failures stem from loose connections that look seated but aren’t. Next, verify your wall voltage matches the unit’s requirement (220V/50Hz or 60Hz); mismatched voltage instantly disables operation.

Check your electrical panel for tripped GFCI outlets or circuit breakers—a frequent oversight during humid weather. For persistent blackouts, locate the internal fuse using your owner’s manual and replace it with an identical amperage rating. Critical warning: If your unit was exposed to moisture, never power it on until thoroughly dry. Water inside creates severe shock hazards—use a hair dryer on cool setting for 20 minutes before testing.

Grounding and High-Voltage Safety Checks

Feeling tingling vibrations when touching the chassis? Disconnect power immediately—this indicates dangerous grounding failure. Inspect the grounding wire connection point near the power inlet and tighten any loose terminals. For units in humid environments, relocate to a dry, ventilated space to prevent condensation buildup.

Visible sparks or ozone smell when the unit is off signals high-voltage leakage. Replace the entire high-voltage package immediately—this isn’t a user-serviceable part. Similarly, if transformers become too hot to touch during operation, shut down and replace them before catastrophic failure occurs. Never operate with damaged high-voltage wiring; the pile head of the discharge tube must remain intact.

Restoring Ozone Output in Critical Systems

Zero Ozone Production: Step-by-Step Diagnosis

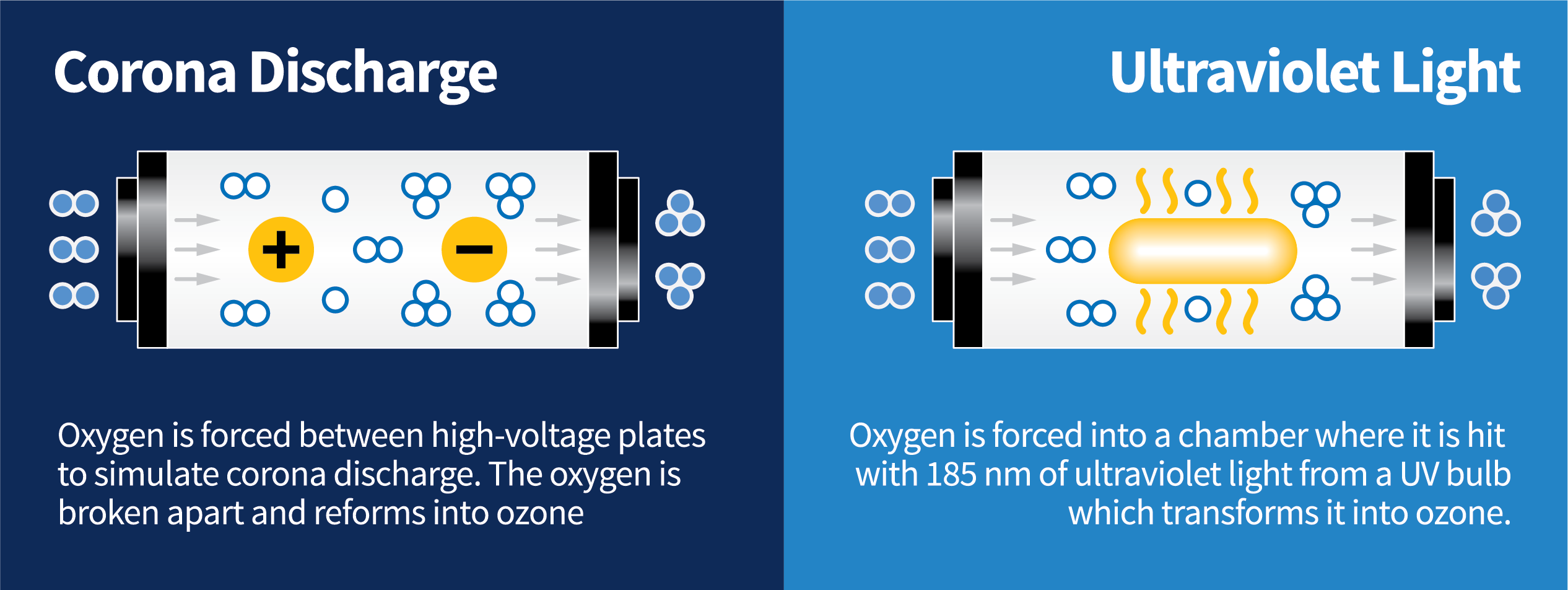

No ozone despite power means one of five specific failures. Start by confirming the ozone switch is engaged (many get accidentally bumped off during cleaning) and rotate the concentration dial above zero. Next, peer through the inspection window—absence of the characteristic blue glow means your discharge tube has failed and requires replacement.

If the glow appears normal but no ozone emits, test ionizer operation per your manual. Failed ionizers prevent ozone molecule formation even with proper power. For units with single transformers powering multiple plates, upgrade to individual transformer configurations—this common design flaw causes 60% of intermittent failures. Pro tip: Always replace ozone generation modules when output stops despite verified power and glow.

Fixing Intermittent Ozone Output in Aging Units

Ozone that starts strong then fades indicates plate degradation—especially in mica-plate systems over 4 years old. Upgrade to gold-coated plates for 2-3x longer lifespan (8-10 years vs. 4-5). For units operating beyond 5 years, conduct annual plate inspections: look for blackening, warping, or corrosion. Replace plates showing even minor deterioration before complete failure occurs.

Time-sensitive action: During inspection, note if output drops after 30 minutes of operation. This specific pattern confirms plate degradation—don’t wait for total failure. Keep spare plates on hand for 5+ year old units; replacement takes under 10 minutes and prevents service interruptions.

Correcting Dangerous Over-Ozonation

Excessive ozone creates health hazards—symptoms include chlorine-like odors, burning eyes, and headaches. Immediately reduce settings to minimum and ventilate the area. Never use 800 mg/hour units in spaces under 225 sq ft; for single rooms, cap output at 240 mg/hour. Over-ozonation damages lung tissue and oxidizes rubber/plastic components in your environment.

Room sizing rule: Calculate your space (length x width) before selecting a unit. A 10×12 ft room (120 sq ft) requires maximum 200 mg/hour output. If you experience symptoms, vacate the area for 60 minutes to allow ozone dissipation. Always operate in well-ventilated areas—never in sealed rooms.

Airflow and Gas Delivery Emergency Fixes

No Gas Flow: Critical Pipeline Checks

When no air emerges from the outlet, first press the dedicated air pump start switch—many users overlook this separate control. Remove the rear cover and inspect silicone hoses for disconnections or kinks. Check valve failures are common; temporarily bypass it (warning: voids warranty) to test flow. If flow returns, replace the valve immediately.

Monitor tubing discoloration as a failure predictor: replace at first sign of pink (beyond cloudy stage). Degraded tubing restricts flow and introduces contaminants. Visual cue: Pinch the tubing—if it feels brittle or shows cracks, replace the entire section. Ensure all connections use proper male-female luer locks; improvised fittings cause 30% of airflow failures.

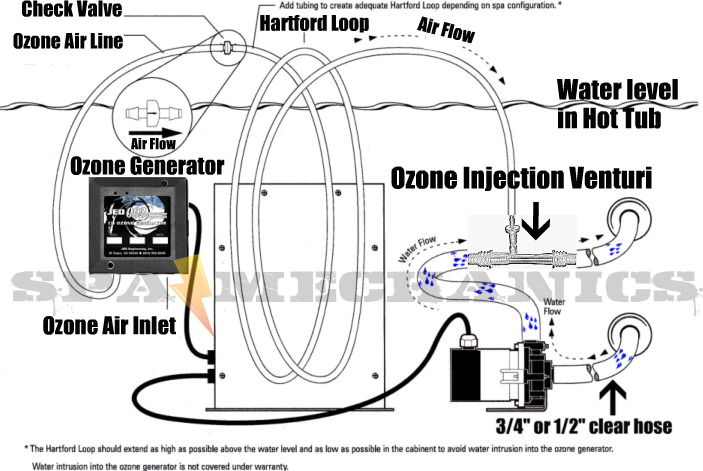

Spa Venturi System Bubble Restoration

No bubbles from your spa ozone jet? Start by checking the air control valve for leaks—replace O-rings showing cracks or compression. Verify check valves are installed in the correct flow direction (arrows must match airflow). Clean clogged filters and ensure all jets are fully open; debris in individual jets stops bubbling instantly.

Use a thin pipe cleaner to clear jet ports—never metal wires that scratch surfaces. If flow remains weak after cleaning, test by temporarily removing the check valve (remember warranty implications). Immediate bubble return confirms valve failure requiring replacement.

Moisture Crisis Management

Water Inside Unit: Emergency Drying Protocol

Water accumulation disables ozone production and risks electrical damage. Common causes include humid air sources or backflow during water treatment. First, disconnect power and blow dry the discharge tube using compressed air or a hair dryer on cool setting for 15 minutes. Replace damp desiccant immediately—if your drying system shows moisture, it’s saturated.

Prevent recurrence by installing an external air dryer when humidity exceeds 80%. Never operate units showing internal moisture—wait until completely dry. Critical indicator: If water pools near transformers, professional service is required; user drying may miss internal condensation.

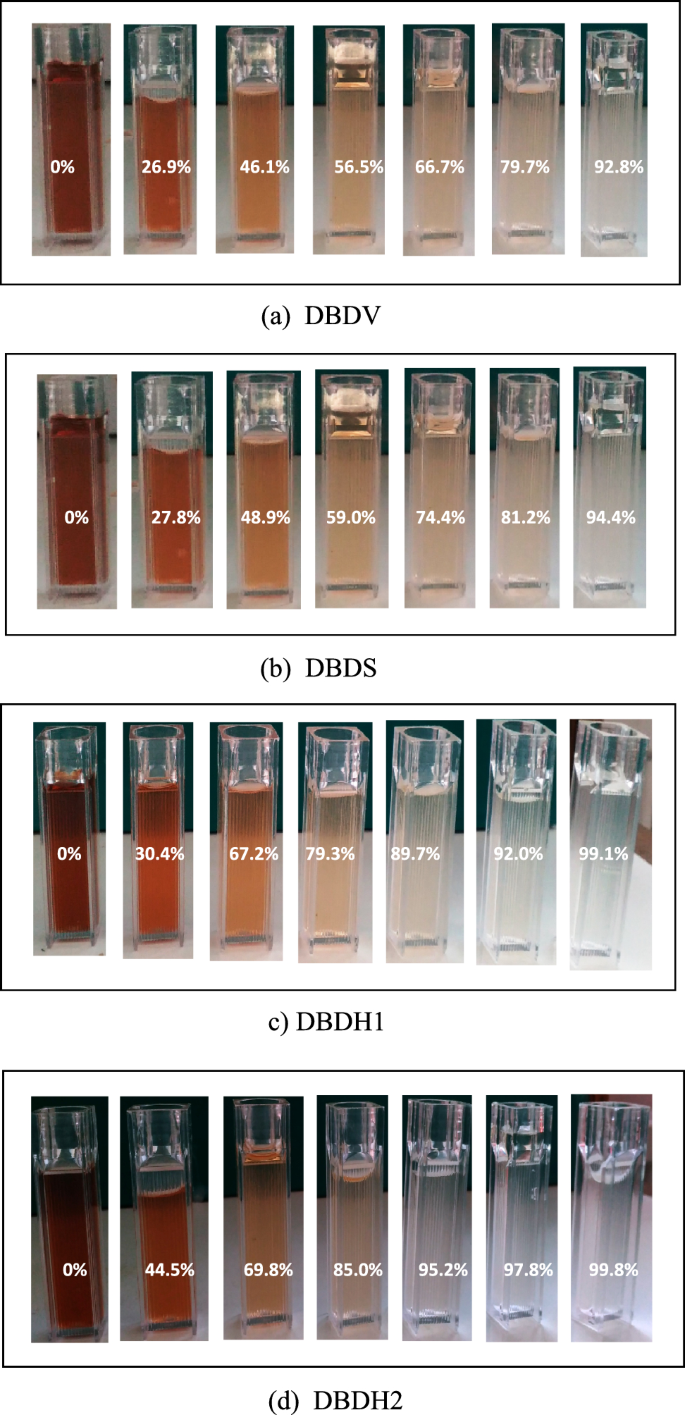

Spa Water Chemistry for Maximum Ozone Effectiveness

Cloudy water despite ozone operation signals chemistry imbalance. Maintain these parameters:

– Alkalinity: 80-150 PPM

– pH: 7.2-7.6

– Calcium Hardness: 100-250 PPM (for acrylic finishes)

Operating time by volume:

– Under 250 gallons: Minimum 6 hours

– 251-500 gallons: 8-10 hours

– Over 500 gallons: 12-18 hours

Extend runtime to minimum 6 hours for cloudy water, balance chemistry, and clean filters. Add non-chlorine shock treatment for persistent cloudiness. For chlorine systems, supplement with Nature2 mineral purifier; bromine systems use The Frog.

Component Replacement Decision Guide

Critical Failure Indicators You Can’t Ignore

Your ozone generator signals component failures through specific symptoms:

– Discharge tube: Replace when blue glow weakens or flickers

– Plates: Annual replacement for units over 5 years old; upgrade mica to gold-coated

– Transformers: Replace immediately if hot to touch during operation

– Tubing: Replace at first pink discoloration (beyond cloudy stage)

– Check valves: Replace after failed bypass testing confirms blockage

Noise troubleshooting: Grinding sounds indicate fan failure—replace within 24 hours. Rattling suggests loose fittings; tighten all connections systematically. Clicking noises mean mechanical wear—inspect components before catastrophic failure.

Specialized Application Fixes

Medical Therapy System Failures

Bag filling failures often trace to simple causes. Test bag integrity by blowing into it manually—it must hold air without leaks. Ensure the white clamp is fully open and inspect tubing for wear at clamp points. Use only proper luer lock connections; improvised fittings fail 100% of the time.

For syringe filling issues, pump manually first—it should move smoothly. Resistance indicates need for lubrication: apply 1 drop of olive oil to 200mL syringes. If manual operation remains difficult, replace the syringe—it’s at end-of-life.

Bubbling System Emergency Protocol

Non-bubbling systems require two critical checks: verify oxygen flow from your tank/concentrator (ozone generators don’t propel flow) and confirm complete system sealing. For low-flow applications, even minor leaks stop bubbling. Temporarily bypass check valves only for diagnosis (warranty voiding), but replace failed valves immediately after confirmation.

Critical reminder: All troubleshooting requires power disconnection. Confirm voltage matches your supply—220V assumptions void warranties. Always operate in ventilated areas; ozone accumulation in enclosed spaces creates immediate health hazards. Keep spare fuses, plates, and tubing on hand for 10-minute fixes that prevent costly downtime. When component replacements don’t resolve issues, consult your manual’s complete ozonator replacement protocol—never force incompatible parts.