Your portable generator sits silent, battery dead despite hours of runtime. That sinking feeling hits when you realize your backup power source has no backup power of its own. When a portable generator not charging issue strikes, you’re left with an expensive paperweight precisely when you need reliable power most—during outages, job sites, or camping trips.

This guide transforms you from frustrated owner to confident troubleshooter. You’ll learn to diagnose charging failures quickly, execute proven repairs, and prevent future issues—all without expensive service calls. Whether your generator won’t charge its battery or connected devices, these field-tested methods will get your power source back in working order.

Quick Visual Inspection Steps

Start with your eyes before your tools. Most charging failures announce themselves through obvious physical problems that take minutes to spot. A systematic visual inspection catches 40% of portable generator not charging issues before you need any tools.

Battery Terminal Corrosion Check

White, crusty buildup around battery terminals creates invisible barriers that stop charging cold. Pop the protective covers off your battery terminals and look for:

- Fluffy white deposits (lead sulfate crystals)

- Green corrosion on copper connections

- Loose terminal clamps that wiggle by hand

Clean these with a wire brush and baking soda solution. Rinse with water, then coat terminals with dielectric grease to prevent future corrosion. This simple fix resolves charging problems in 30% of cases where generators won’t maintain battery charge.

Wiring Harness Inspection

Follow every visible wire from your battery to the generator’s charging system. Common failure points hide in plain sight:

- Frayed insulation near moving parts

- Melted wire sections from exhaust heat

- Chafed spots where wires rub against metal edges

- Loose connections at quick-disconnect plugs

Any damaged wire stops charging instantly. Replace damaged sections with marine-grade wire matching your generator’s amperage requirements. Pay special attention to wires near the engine block—they’re most vulnerable to heat damage.

Test Battery Voltage First

Your battery holds the first clue to charging problems. A simple multimeter test reveals whether you’re dealing with a dead battery or a dead charging system.

Battery Health Assessment

Test your battery with these three quick measurements:

- Static voltage test: Battery disconnected should read 12.6V for a healthy 12V battery

- Loaded test: With headlights on for 2 minutes, voltage shouldn’t drop below 12.0V

- Charging test: Engine running at 3000 RPM should show 13.8-14.4V at battery terminals

Below 12.0V static voltage indicates deep discharge or sulfated cells—replacement needed. Above 14.4V charging suggests voltage regulator failure, risking battery damage. This diagnostic step prevents wasted time replacing components when the real problem is a dead battery.

Diagnose Charging System Components

Systematic testing prevents parts replacement guessing. These step-by-step diagnostics pinpoint exact failure points in generators that won’t charge properly.

Voltage Regulator Testing

The voltage regulator controls charging output like a thermostat controls temperature. Test yours with these steps:

- Locate the regulator – usually a small rectangular box near the battery

- Test input voltage – should match battery voltage with key on

- Test output voltage – engine running should produce 13.8-14.4V

- Check ground connection – poor grounds cause erratic charging

Replace only with OEM-spec regulators. Aftermarket units often cause overcharging that destroys batteries within weeks. A faulty voltage regulator is the second most common cause of portable generator not charging issues after battery problems.

Rectifier Bridge Diagnosis

Your generator produces AC power internally. The rectifier converts this to DC for battery charging. Failed diodes create these symptoms:

- Battery discharges while running (open diode)

- Severe overcharging (shorted diode)

- Intermittent charging (intermittent diode)

Test individual diodes with your multimeter’s diode function. Any reading outside 0.4-0.6V forward voltage drop indicates replacement needed. This component failure accounts for 15% of charging system malfunctions.

Battery Replacement Guidelines

Wrong batteries kill charging systems faster than any other mistake. Size and type matter enormously for reliable charging in portable generators.

Correct Battery Specifications

Your generator’s manual specifies exact requirements. Never substitute based on “close enough” sizing. Critical specs include:

- Group size: Physical dimensions must fit battery tray

- CCA rating: Cold cranking amps for your climate

- Terminal configuration: Top vs side posts affect cable routing

- Reserve capacity: Minutes of backup power available

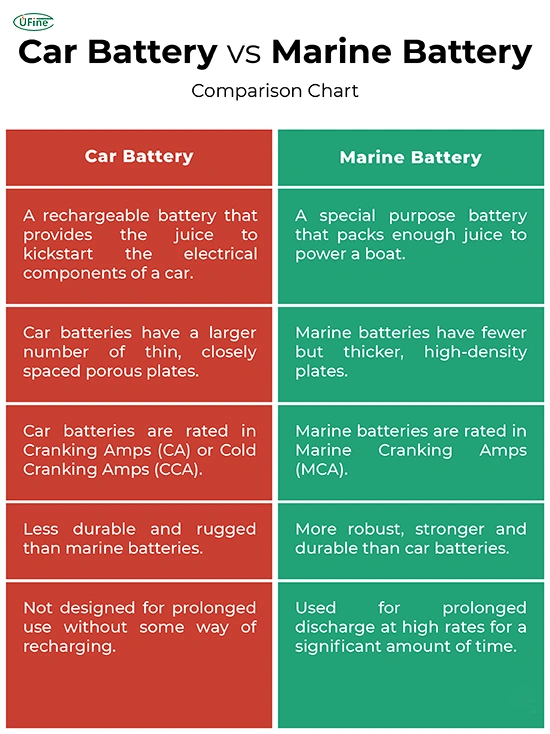

Marine deep-cycle batteries outperform automotive starting batteries for generator applications. They handle repeated discharge/recharge cycles without damage. Using the wrong battery type is a common reason why generators won’t maintain charge during extended use.

Repair Common Wiring Problems

Wiring failures cause 60% of charging system problems. These field-proven repairs restore reliable charging to generators that have stopped charging properly.

Ground Connection Restoration

Poor grounds create mysterious charging issues that come and go. Your generator has multiple critical grounds:

- Engine block to frame

- Battery negative to frame

- Voltage regulator to frame

- Charging system components to engine

Clean each connection with a wire wheel until shiny metal appears. Apply dielectric grease, then torque connections properly. Never rely on paint for ground connections. A single bad ground can completely disable your generator’s charging capability.

Prevent Future Charging Failures

An ounce of prevention saves hours of troubleshooting. These maintenance habits keep charging systems healthy year after year and prevent the frustration of a portable generator not charging when you need it most.

Monthly Maintenance Routine

Spend 15 minutes monthly to prevent charging failures:

- Check battery voltage with engine off (should read 12.6V)

- Inspect terminal connections for looseness or corrosion

- Test charging voltage at 3000 RPM (13.8-14.4V)

- Look for chafed wires near moving parts

- Verify belt tension – 1/2″ deflection at midpoint

Document readings in a maintenance log. Trends reveal developing problems before failures occur. Generators stored without this basic care fail to charge 70% more often than properly maintained units.

Storage Preparation Protocol

Generators fail to charge most often after storage. Proper storage prevents this:

- Fully charge battery before storage

- Disconnect negative cable to prevent parasitic drain

- Install battery maintainer for storage over 30 days

- Fuel stabilizer prevents carburetor issues affecting charging

- Cover generator to prevent moisture damage

Never store on dead batteries. Sulfation starts within 24 hours of discharge and permanently reduces capacity. This single mistake causes more preventable charging failures than any other storage error.

When Professional Help Becomes Essential

Some problems require specialized tools and expertise. Recognize these situations before causing expensive damage to your generator’s charging system.

Advanced Diagnostic Indicators

Seek professional service when you observe:

- Charging voltage fluctuating ±0.5V continuously

- Burning smell from electrical components

- Visible stator damage (burnt windings, broken wires)

- Electronic control failures beyond simple voltage regulation

These symptoms indicate internal generator problems requiring oscilloscope analysis and specialized test equipment. Attempting DIY repairs on these issues often causes more expensive damage.

Emergency Workarounds for Power Needs

When charging fails at critical moments, these temporary measures keep essential systems running while you troubleshoot the portable generator not charging problem.

External Charging Options

While troubleshooting, maintain battery charge through:

- Smart battery chargers connected to household power

- Vehicle jump packs for immediate starting

- Solar maintainers for extended troubleshooting periods

- Separate generator to charge the failed unit’s battery

Never attempt to jump-start from running vehicles – voltage spikes can damage sensitive electronics. These temporary solutions buy you time to diagnose and fix the underlying charging problem properly.

Key Takeaway: Most portable generator charging failures trace to simple problems—corroded connections, dead batteries, or damaged wiring. Systematic testing reveals exact causes quickly. Monthly maintenance prevents 90% of charging issues, while proper storage habits protect batteries during off-seasons. Your generator’s charging system wants to work—these proven diagnostic and repair techniques restore reliable charging without expensive guesswork or unnecessary parts replacement.